Biological gasifying furnace

A gasifier and biological technology, which is applied in the field of stoves, can solve the problems of no stoves, low combustion value of biofuels, and prolonged cooking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

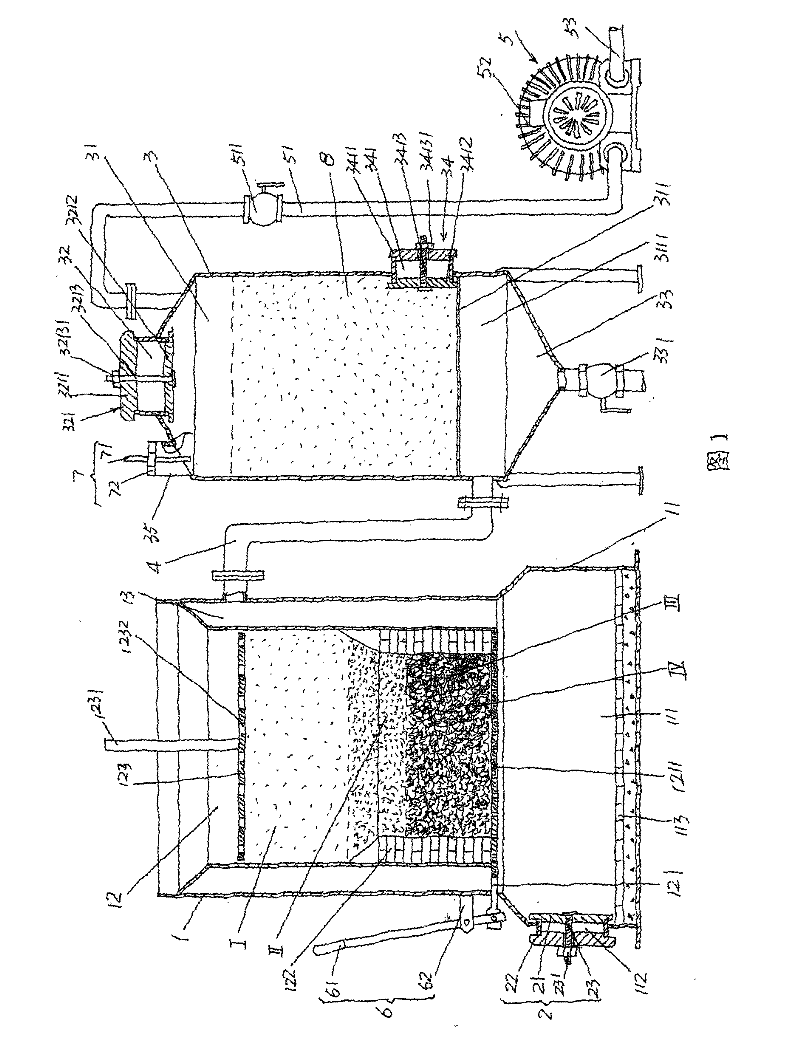

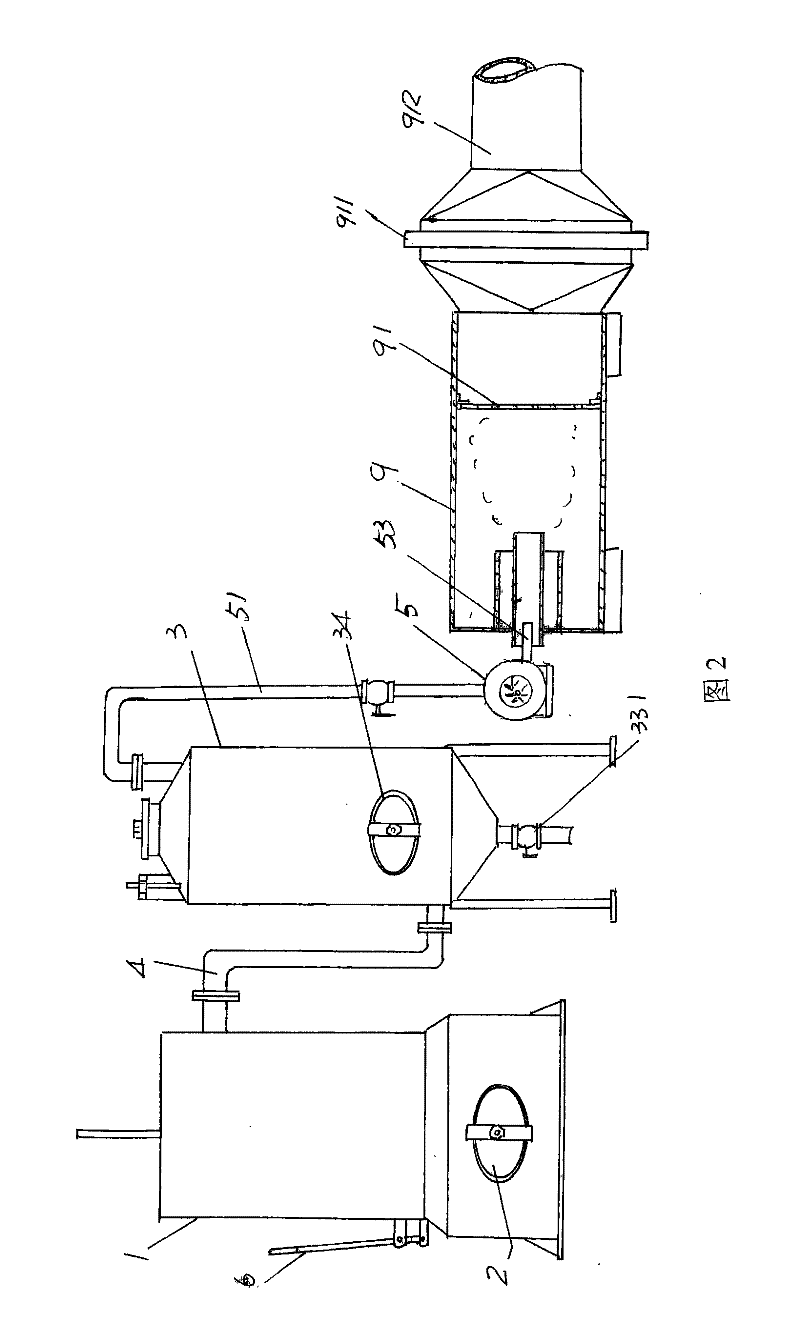

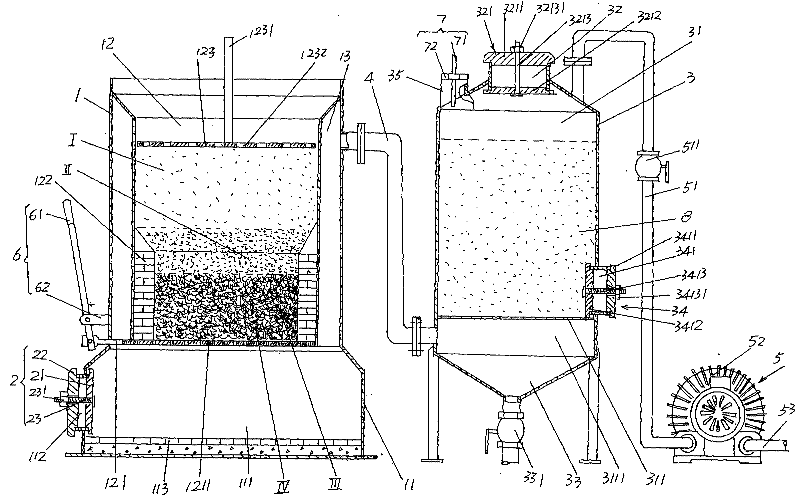

[0021] Please see figure 1 , the specifications are given, that is, the size of the furnace body 1 does not need to be limited but can be large or small according to the requirements of use. In general, the furnace body 1 is in the shape of a cylinder, and the applicant recommends a cylinder shape. Furnace body 1. The lower part of the furnace body 1 is formed as a base 11, and the base 11 forms an integral structure with the furnace body 1. The inside of the furnace body 1, that is, the upper part of the base 11, constitutes a furnace cavity 12, which can also be called For the furnace. A spacer 13 is formed between the outer wall of the furnace cavity 12 and the inner wall of the furnace body 1 , and the spacer 13 communicates with the ash chamber 111 of the aforementioned base 11 . A refractory layer 122 is laid around the lower part of the furnace cavity 12. The refractory layer 122 can use refractory bricks or pouring materials such as concrete or other equivalent refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com