Reinforced dump leaching method of low grade molybdenite

A molybdenite and enhanced reactor technology, applied in the direction of improving process efficiency, can solve problems such as unsatisfactory economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The grade of molybdenum in molybdenite is 0.051%.

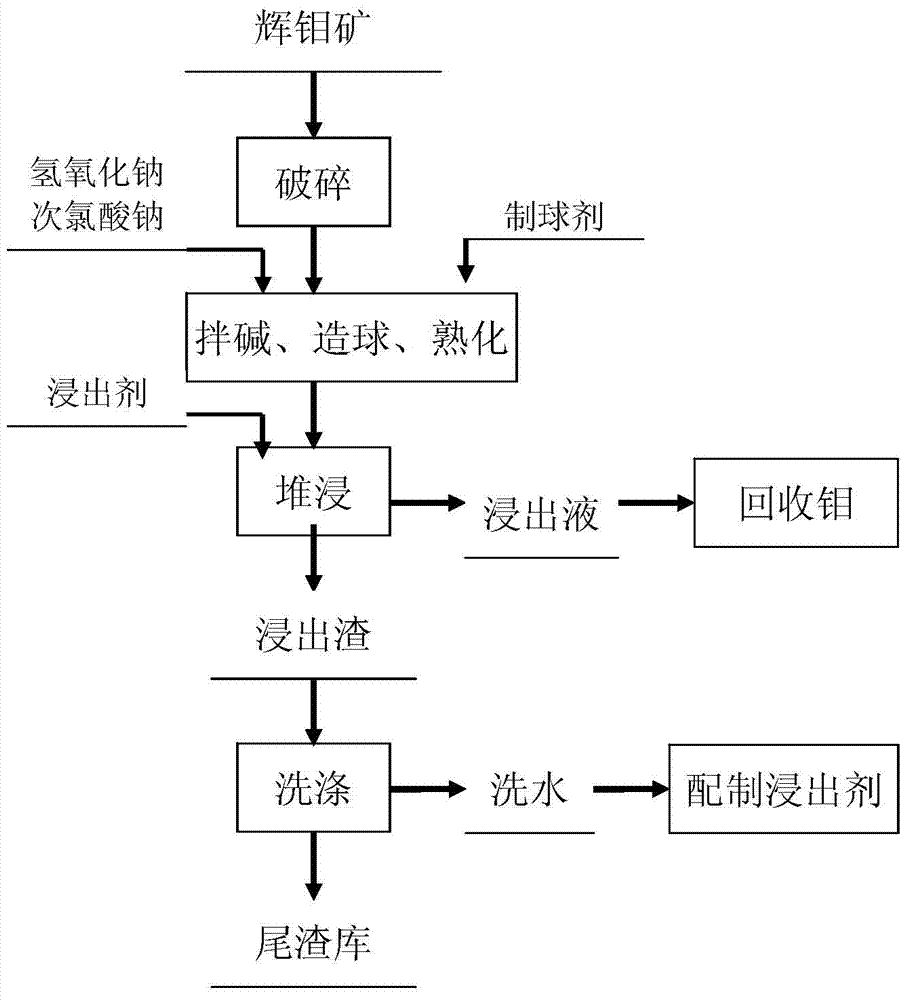

[0039] Adopt the method described in the present invention to comprise the steps:

[0040] (1) Crushing: Crushing the ore particle size to -0.5mm.

[0041](2) Soda mixing, pelletizing, slaking: Add 0.5% sodium hydroxide (ratio to ore mass), 0.5% oxidant (mass ratio to ore) and 0.1% pelleting agent to the ore obtained in step (1), according to the liquid-solid ratio Stir at 0.20L / kg to make the leaching agent and ore evenly infiltrate and make balls; the wet ore after ball making is packed into a column and matured at 5°C for 1 day.

[0042] (3) Leaching: Use 2g / L sodium hydroxide and 1g / L sodium hypochlorite solution as leaching agents for the wet ore obtained in step (2), and heap leaching for 20 days at a temperature of 5°C.

[0043] (4) Treatment of leachate: the leachate obtained in step (3) is prepared by ion exchange or precipitation to prepare products such as ammonium molybdate or calcium molybdate. The leac...

Embodiment 2

[0046] The grade of molybdenum in molybdenite is 0.5%.

[0047] Adopt the method described in the present invention to comprise the steps:

[0048] (1) Crushing: Crushing the ore to a particle size of 5mm.

[0049] (2) Soda mixing, pelletizing, slaking: add 5% sodium hydroxide (ratio to ore mass), 5% oxidant (mass ratio to ore) and 8% pelleting agent to the ore obtained in step (1), according to the liquid-solid ratio Stir at 0.05L / kg to make the leaching agent and ore uniformly infiltrate and make balls; the wet ore after ball making is packed into a column and matured at 40°C for 10 days.

[0050] (3) Leaching: Use 40g / L sodium hydroxide and 10g / L sodium hypochlorite solution as leaching agents for the wet ore obtained in step (2), and heap leaching for 7 days at a temperature of 40°C.

[0051] (4) Treatment of leachate: the leachate obtained in step (3) is prepared by ion exchange or precipitation to prepare products such as ammonium molybdate or calcium molybdate. The l...

Embodiment 3

[0054] The grade of molybdenum in molybdenite is 0.114%.

[0055] Adopt the method described in the present invention to comprise the steps:

[0056] (1) Crushing: Crushing the ore to a particle size of 3mm.

[0057] (2) Soda mixing, pelletizing, slaking: Add 1.5% sodium hydroxide (ratio to ore mass), 1.5% oxidant (mass ratio to ore) and 2% pelleting agent to the ore obtained in step (1), according to the liquid-solid ratio Stir at 0.20L / kg to make the leaching agent and ore uniformly infiltrate and make balls; the wet ore after ball making is packed into a column and matured at 20°C for 5 days.

[0058] (3) Leaching: Use 20g / L sodium hydroxide and 5g / L sodium hypochlorite solution as leaching agents for the wet ore obtained in step (2), and heap leaching for 10 days at a temperature of 20°C.

[0059] (4) Treatment of leachate: the leachate obtained in step (3) is prepared by ion exchange or precipitation to prepare products such as ammonium molybdate or calcium molybdate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com