A method for enhancing biological oxidation of arsenic-containing gold ore through potential regulation and control

A technology of biological oxidation and gold ore, applied in the direction of improving process efficiency, etc., can solve the problems that the total iron content is unfavorable to the growth and reproduction of bacteria, unfavorable to the oxidation and dissolution of arsenic and gold ore, and the unfavorable bioleaching process, so as to facilitate the oxidation rate and shorten the leaching Cycle, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

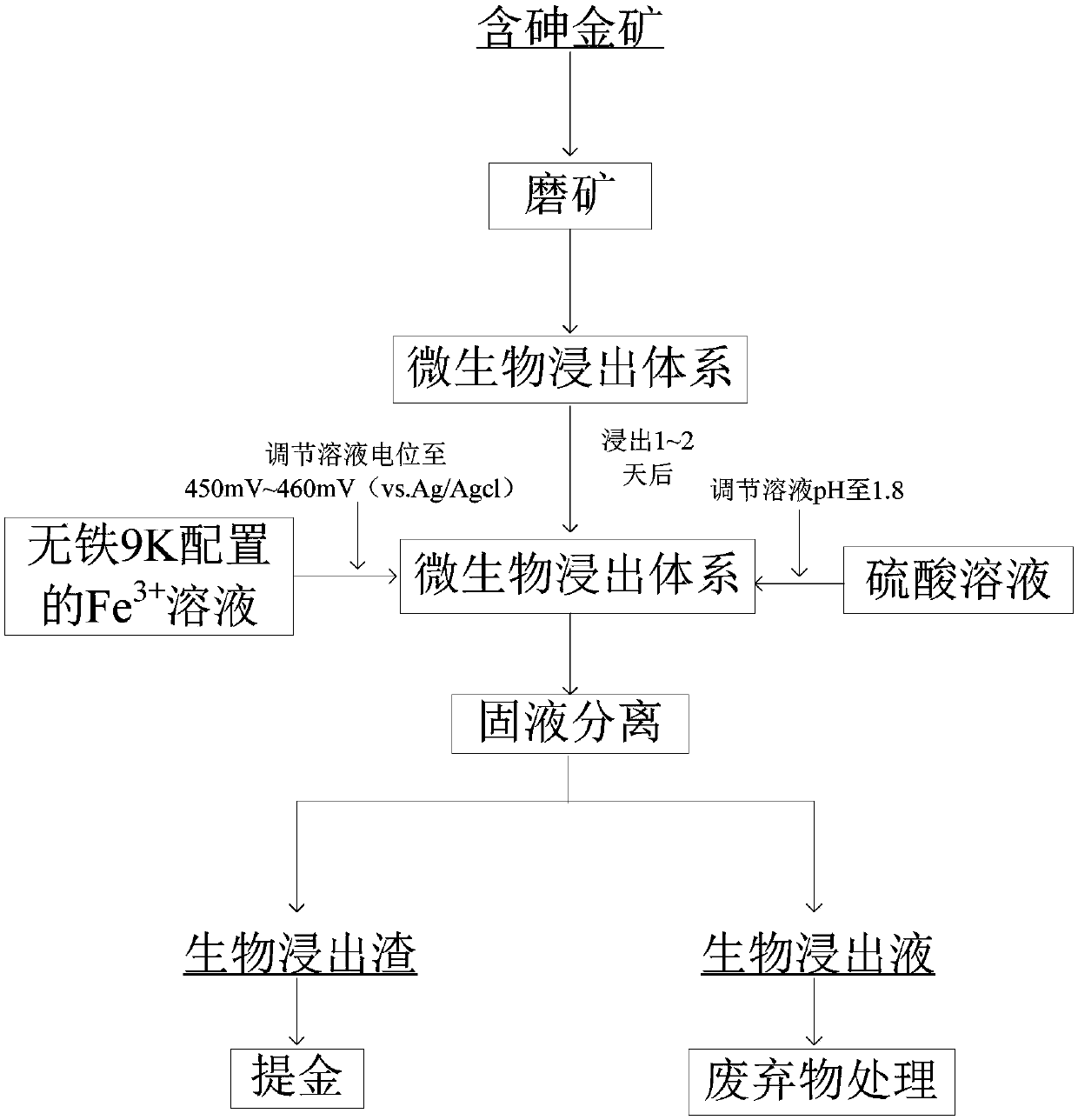

[0030] like figure 1 As shown, a method for regulating potential to strengthen the biooxidation of arsenic-containing gold ore, comprising the following steps:

[0031] (1) Using wet or dry grinding to finely grind the arsenic-containing gold ore into ore powder, and make the content of the part of the ore powder whose particle size is less than 0.074mm account for more than 80% of the total ore powder mass;

[0032] (2) Using the preparation of Fe-containing 2+ 9K medium, and then use Fe-free 2+ Fe 3+ Solution; Wherein, the main component of 9K culture medium is: (NH 4 ) 2 SO 4 The content is 3.0g / L, MgSO 4 ·7H 2 O content is 0.5g / L, K 2 HPO 4 ·3H 2 O content is 0.5g / L, KCl content is 0.1g / L, Ca(NO 3 ) 2 4H 2 O content is 0.01g / L, FeSO 4 ·7H 2 O content is 29.8g / L; Fe 3+ The main components of the solution are: (NH 4 ) 2 SO 4 The content is 3.0g / L, MgSO 4 ·7H 2 O content is 0.5g / L, K 2 HPO 4 ·3H 2 O content is 0.5g / L, KCl content is 0.1g / L, Ca(NO 3 ) ...

Embodiment 2

[0048] A method for regulating potential to strengthen biooxidation of arsenic-containing gold ore, comprising the following steps:

[0049] (1) Using wet or dry grinding to finely grind the arsenic-containing gold ore into ore powder, and make the content of the part of the ore powder whose particle size is less than 0.074mm account for more than 80% of the total ore powder mass;

[0050] (2) Using the preparation of Fe-containing 2+ 9K medium, and then use Fe-free 2+ Fe 3+ Solution; Wherein, the main component of 9K culture medium is: (NH 4 ) 2 SO 4 The content is 3.0g / L, MgSO 4 ·7H 2 O content is 0.5g / L, K 2 HPO 4 ·3H 2 O content is 0.5g / L, KCl content is 0.1g / L, Ca(NO 3 ) 2 4H 2 O content is 0.01g / L, FeSO 4 ·7H 2 O content is 29.8g / L; Fe 3+ The main components of the solution are: (NH 4 ) 2 SO 4 The content is 3.0g / L, MgSO 4 ·7H 2 O content is 0.5g / L, K 2 HPO 4 ·3H 2 O content is 0.5g / L, KCl content is 0.1g / L, Ca(NO 3 ) 2 4H 2 O content is 0.01g / L...

Embodiment 3

[0066] A method for regulating potential to strengthen biooxidation of arsenic-containing gold ore, comprising the following steps:

[0067] (1) Using wet or dry grinding to finely grind the arsenic-containing gold ore into ore powder, and make the content of the part of the ore powder whose particle size is less than 0.074mm account for more than 80% of the total ore powder mass;

[0068] (2) Using the preparation of Fe-containing 2+ 9K medium, and then use Fe-free 2+ Fe 3+ Solution; Wherein, the main component of 9K culture medium is: (NH 4 ) 2 SO 4 The content is 3.0g / L, MgSO 4 ·7H 2 O content is 0.5g / L, K 2 HPO 4 ·3H 2 O content is 0.5g / L, KCl content is 0.1g / L, Ca(NO 3 ) 2 4H 2 O content is 0.01g / L, FeSO 4 ·7H 2 O content is 29.8g / L; Fe 3+ The main components of the solution are: (NH 4 ) 2 SO 4 The content is 3.0g / L, MgSO 4 ·7H 2 O content is 0.5g / L, K 2 HPO 4 ·3H 2 O content is 0.5g / L, KCl content is 0.1g / L, Ca(NO 3 ) 2 4H 2 O content is 0.01g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com