Chalcocite-contained coarse-grain disseminated copper sulfide ore step-by-step ore grinding flotation method

A copper sulfide, coarse-grained technology, applied in flotation, chemical instruments and methods, solid separation, etc., can solve the problems of insufficient flotation time, tailing of useful minerals, excessive crushing and loss, etc., and achieves easy industrial application and production cost. Low, the effect of achieving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

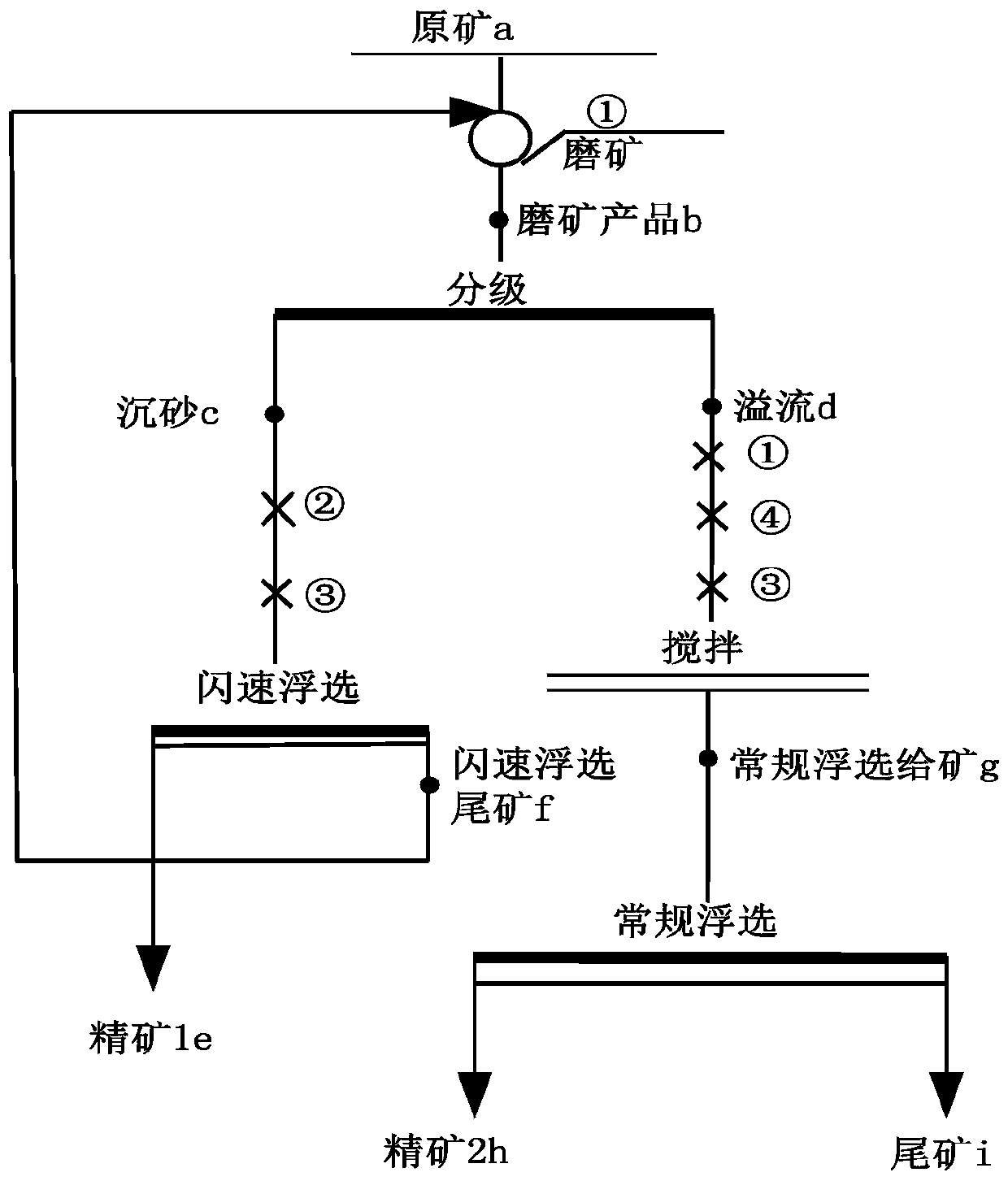

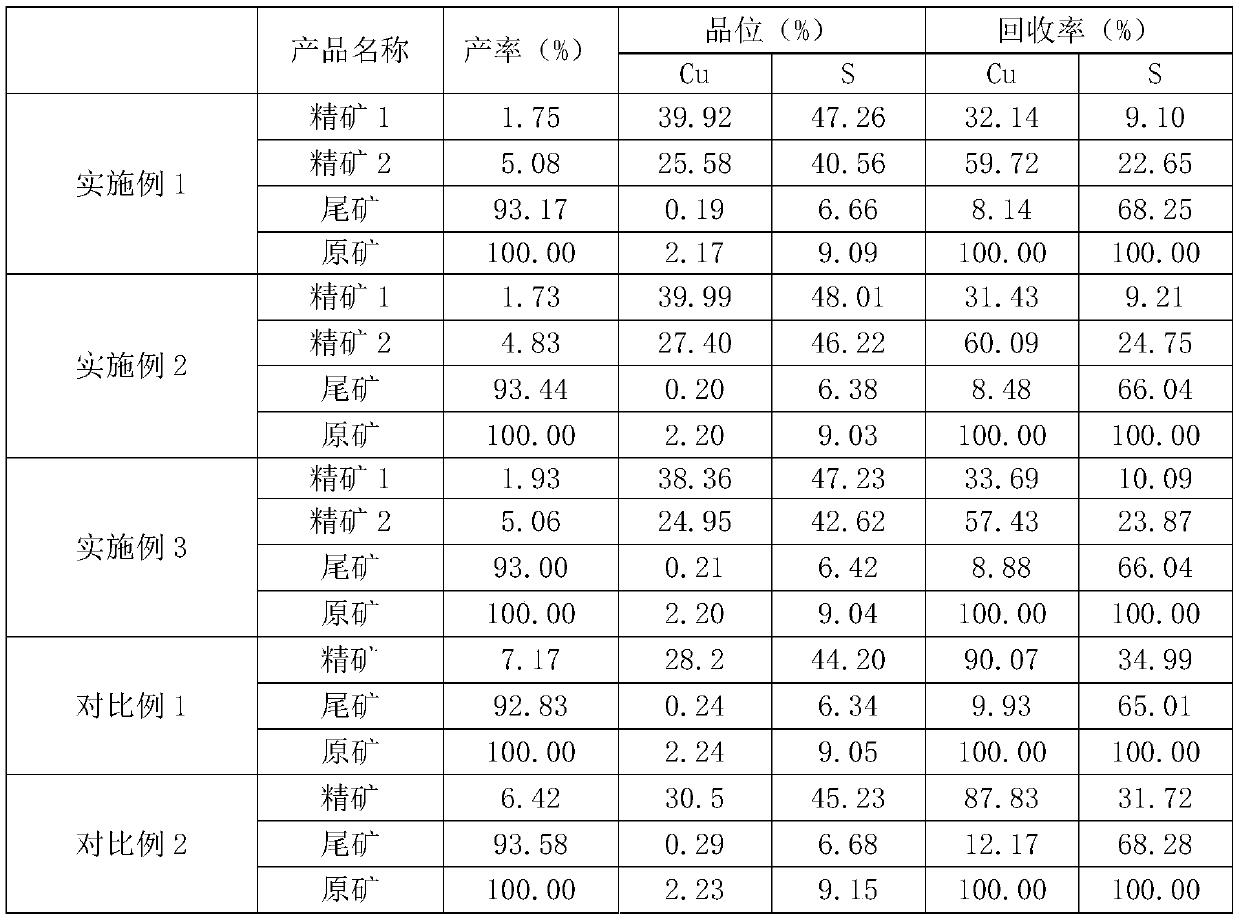

Embodiment 1

[0031] According to the dry weight of copper sulfide ore per ton, 1000g / t of calcium oxide is added to the raw ore, and after ball milling until the ore discharge is -74um, about 25% enters the classification system, and the graded sand fineness is -74um, accounting for 15%, and the graded overflow The fineness is -74um, accounting for 65%. The graded sand settling directly enters the flash flotation system, and the graded overflow enters the conventional flotation system. The dosage of highly selective collector LY01 is 15g / t, and the dosage of foaming agent 2# oil is 10g / t. After flash flotation, the yield of concentrate 1 is 1.75%, the grade of copper is 39.82%, and the grade of sulfur is 47.26%; graded overflow enters the conventional flotation operation, adding a strong collector LY02 dosage of 30g / t, foaming agent 2# oil dosage of 15g / t and sorting, the yield of concentrate 2 is 5.08%, the copper grade is 25.58%, and the sulfur grade is 40.56%; the comprehensive concentr...

Embodiment 2

[0033] According to the dry weight of copper sulfide ore per ton, 1000g / t of calcium oxide is added to the raw ore, and after ball milling until the ore discharge is -74um, about 25% enters the classification system, and the graded sand fineness is -74um, accounting for 15%, and the graded overflow The fineness is -74um, accounting for 64%. The graded sand settling directly enters the flash flotation system, and the graded overflow enters the conventional flotation system. The dosage of highly selective collector LY01 is 13g / t, and the dosage of foaming agent 2# oil is 12g / t. After flash flotation, the yield of concentrate 1 is 1.73%, the grade of copper is 39.99%, and the grade of sulfur is 48.01%; graded overflow enters the conventional flotation operation, adding a strong collector LY02 dosage of 28g / t, foaming agent 2# oil dosage of 18g / t and then sorting, the yield of concentrate 2 is 4.83%, the copper grade is 27.40%, the sulfur grade is 46.22%; the comprehensive concent...

Embodiment 3

[0035] According to the dry weight of copper sulfide ore per ton, 1000g / t of calcium oxide is added to the raw ore, and after ball milling until the ore discharge is -74um, about 25% enters the classification system, and the graded sand fineness is -74um, accounting for 15%, and the graded overflow The fineness is -74um, accounting for 63%. The graded sand settling directly enters the flash flotation system, and the graded overflow enters the conventional flotation system. The dosage of highly selective collector LY01 is 15g / t, and the dosage of foaming agent 2# oil is 12g / t. After flash flotation, the yield of concentrate 1 is 1.93%, the grade of copper is 38.36%, and the grade of sulfur is 47.23%; graded overflow enters the conventional flotation operation, adding a strong collector LY02 dosage of 35g / t, foaming agent 2# oil dosage of 12g / t and then sorting, the yield of concentrate 2 is 5.06%, the copper grade is 24.95%, the sulfur grade is 42.62%; the comprehensive concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com