Floatation depressant and methods for preparing and using depressing agent

A depressant and flotation technology, applied in flotation, solid separation, etc., can solve the problems of inconvenient operation and achieve the effects of less dosage, safe use and convenient addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

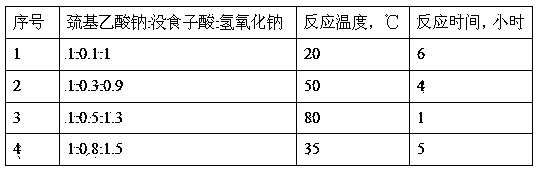

[0025] An example of the preparation method of the inhibitor of the present invention comprises the following steps:

[0026] In the reactor, add thioglycolic acid, gallic acid, and sodium hydroxide at a molar ratio of 1:0.5:1.7, keep the reaction temperature at 50°C for 4 hours, and cool to obtain a clear and transparent solution, which is the flotation inhibitor.

[0027]

Embodiment 2

[0029] Another example of the preparation method of the inhibitor of the present invention comprises the following steps:

[0030] In the reactor, add thioglycolic acid, gallic acid, and sodium hydroxide at a molar ratio of 1.5:0.4:2.3, keep the reaction temperature at 70°C for 2 hours, and cool to obtain a clear and transparent solution, which is the flotation inhibitor.

Embodiment 3

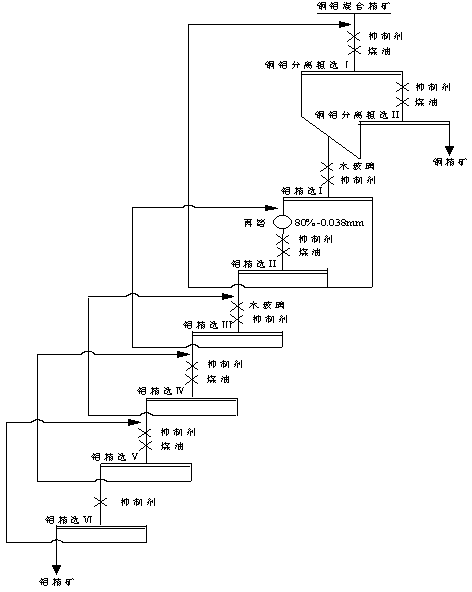

[0032] This embodiment is an application example of separating copper-molybdenum minerals in copper-molybdenum mixed flotation concentrate by the flotation inhibitor.

[0033] A copper-molybdenum sulfide ore was subjected to copper-molybdenum mixed flotation to obtain copper-molybdenum mixed concentrate. The mixed concentrate contained 0.32% molybdenum and 22.65% copper. , and sequentially add water glass, inhibitor, kerosene, and stir, after two times of roughing and six times of beneficiation, a molybdenum concentrate containing 46.15% molybdenum and 0.79% copper can be obtained. The amount of water glass added is 1500g / t for ore, the amount of inhibitor added is 6500g / t for ore, and the amount of kerosene added is 150g / t for ore. The inhibitor is the flotation inhibitor prepared in Example 1 or Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com