Method for preparing polybutadiene rubber latex with extra large particle size

A technology of polybutadiene latex and particle size, which is applied in the field of preparation of polybutadiene latex with a super-large particle size of 400-1000nm, can solve the problems that do not involve the preparation method of polymer agglomerating agent and agglomeration process, and achieve agglomeration The polymerization process is controllable, the preparation process is simple, and the effect of improving the impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

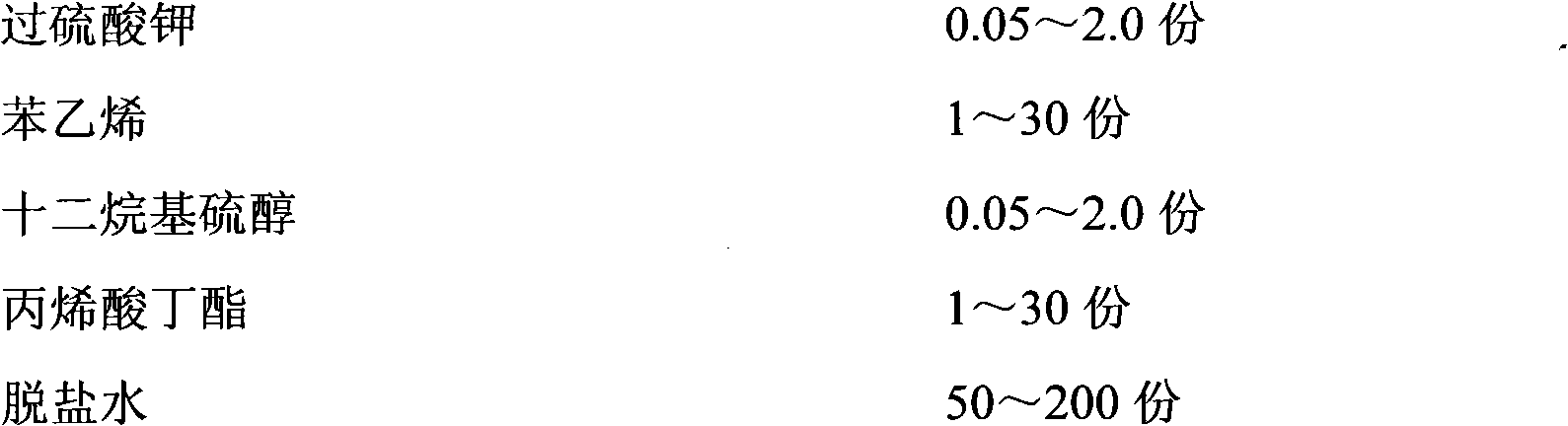

[0034] (1) Synthesis of polymer agglomerating agent

[0035] deionized water, sodium bicarbonate (NaHCO 3 ), Sodium Dodecyl Sulfate (SDS), Potassium Persulfate (KPS), Dodecyl Mercaptan (TDDM), Butyl Acrylate (BA) and Styrene (ST) are added with agitator and reflux condenser , Thermometer in a four-neck bottle, put it into a water bath, start stirring and emulsifying, replace it with nitrogen gas, raise the temperature, when the temperature reaches 55°C, start timing, and add the mixed monomers dropwise after 1 hour of polymerization, including BA, methacrylic acid (MMA), ST, OP-10, react for 2 hours, raise the temperature to 75°C, stir for another 1 hour to complete the reaction, cool down and filter.

[0036] (2) Add the polymer agglomerating agent into the polybutadiene latex in a certain proportion (ratio of dry parts), stir slowly for 10 minutes while adding, and place for more than 4 hours.

[0037] (3) Components and parts by weight

[0038] 1) The components and part...

Embodiment 2

[0048] (1) Synthesis of polymer agglomerating agent

[0049] deionized water, sodium bicarbonate (NaHCO 3 ), Sodium Dodecyl Sulfate (SDS), Potassium Persulfate (KPS), Dodecyl Mercaptan (TDDM), Butyl Acrylate (BA) and Styrene (ST) are added with agitator and reflux condenser , Thermometer in a four-neck bottle, put it into a water bath, start stirring and emulsifying, replace it with nitrogen gas, raise the temperature, when the temperature reaches 60°C, start timing, and add the mixed monomers dropwise after polymerization for 0.5 hours, including BA, methacrylic acid (MMA), ST, OP-10, react for 2.5 hours, raise the temperature to 80°C, stir for another 1 hour to complete the reaction, cool down and filter.

[0050] (2) Add the polymer agglomerating agent into the polybutadiene latex in a certain proportion (ratio of dry parts), stir slowly for 10 minutes while adding, and place for more than 4 hours.

[0051] (3) Components and parts by weight

[0052] 1) The components an...

Embodiment 3

[0062] (1) Synthesis of polymer agglomerating agent

[0063] deionized water, sodium bicarbonate (NaHCO 3 ), Sodium Dodecyl Sulfate (SDS), Potassium Persulfate (KPS), Dodecyl Mercaptan (TDDM), Butyl Acrylate (BA) and Styrene (ST) are added with agitator and reflux condenser , Thermometer in a four-neck bottle, put it into a water bath, start stirring and emulsifying, replace it with nitrogen, raise the temperature, when the temperature reaches 58°C, start timing, and add the mixed monomers dropwise after 1 hour of polymerization, including BA, methacrylic acid (MMA), ST, OP-10, react for 2.5 hours, raise the temperature to 78°C, stir for another 1.5 hours to complete the reaction, cool down and filter.

[0064] (2) Add the polymer agglomerating agent into the polybutadiene latex in a certain proportion (ratio of dry parts), stir slowly for 10 minutes while adding, and place for more than 4 hours.

[0065] (3) Components and parts by weight:

[0066] 1) The components and pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com