Resin for UV-cured strippable protection film, preparation method and applications thereof

A technology of protective film and ultraviolet light, which is applied in the direction of coating, etc., can solve the problems of affecting efficiency, wasting energy, and fogging on the protected surface, and achieves the effect of energy saving and no VOC pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

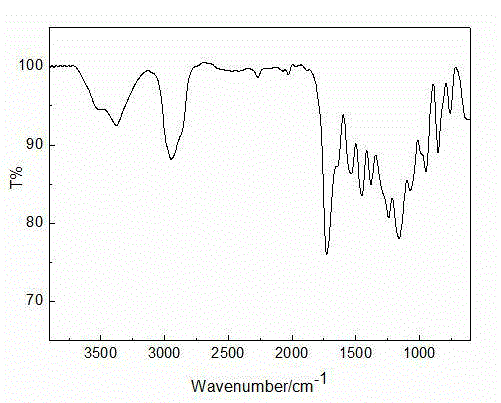

Image

Examples

Embodiment 1

[0036] 1) Weigh 60g of methyl methacrylate, 40g of butyl acrylate, 10g of acrylic acid, 40g of hydroxypropyl acrylate, 50g of isooctyl methacrylate and 200g of ethyl acetate, and the total mass of the above five acrylic acid monomers is 3.5 % of azobisisobutyronitrile is mixed uniformly, and nitrogen gas is introduced;

[0037] 2) Take 10% of the total mass of the above mixture and place it in a four-neck flask equipped with a stirring rod, condenser, constant pressure burette and thermometer, and react at a temperature of 75±1°C for 30 minutes; slowly add the remaining mixture The liquid content is 5.0% dodecyl mercaptan of the total mass of the 5 kinds of acrylic acid monomers described in step 1), and the reaction is continued for 1 h after the dropwise addition is completed;

[0038] 3) Dissolve azobisisobutyronitrile with a content of 1.5% of the total mass of the five acrylic acid monomers described in step 1) in 20ml of ethyl acetate, and slowly add it dropwise to the r...

Embodiment 2

[0044] 1) Weigh 40g of methyl methacrylate, 30g of butyl acrylate, 20g of acrylic acid, 30g of hydroxypropyl acrylate, 30g of isooctyl methacrylate and 150g of ethyl acetate, and the total mass of the above five acrylic acid monomers is 1.4 % of azobisisobutyronitrile is mixed uniformly, and nitrogen gas is introduced;

[0045] 2) Take 5% of the total mass of the above mixture and place it in a four-neck flask equipped with a stirring rod, condenser, constant pressure burette and thermometer, and react at a temperature of 75±1°C for 30 minutes; slowly add the remaining mixture The liquid content is 1.0% dodecyl mercaptan of the total mass of the 5 kinds of acrylic acid monomers described in step 1), and the reaction is continued for 1 h after the dropwise addition is completed;

[0046] 3) Dissolve azobisisobutyronitrile with a content of 1.5% of the total mass of the five acrylic acid monomers described in step 1) in 15ml of ethyl acetate, and slowly add it dropwise to the re...

Embodiment 3

[0051] 1) Weigh 60g of methyl methacrylate, 30g of butyl acrylate, 20g of acrylic acid, 40g of hydroxypropyl acrylate, 50g of isooctyl methacrylate and 200g of ethyl acetate, and the total mass of the above five acrylic acid monomers is 3.0 % of azobisisobutyronitrile is mixed uniformly, and nitrogen gas is introduced;

[0052] 2) Take 10% of the total mass of the above mixture and place it in a four-neck flask equipped with a stirring rod, condenser, constant pressure burette and thermometer, and react at a temperature of 75±1°C for 30 minutes; slowly add the remaining mixture The liquid content is 1.5% dodecyl mercaptan of the total mass of the 5 kinds of acrylic acid monomers described in step 1), and the reaction is continued for 1 h after the dropwise addition is completed;

[0053] 3) Use 20ml of ethyl acetate to dissolve azobisisobutyronitrile with a content of 1.5% of the total mass of the five acrylic acid monomers described in step 1), and slowly add it dropwise to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com