Preparation method of high-strength wood-plastic composite material and high-strength wood-plastic composite material

A wood-plastic composite material and high-strength technology, applied in the field of furniture manufacturing, can solve the problems of inability to meet the relevant strength requirements of key structural parts of furniture, insufficient mechanical strength, and short service life, and achieve improved mechanical strength, strong corrosion resistance, Effects for easy re-manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The preparation method of the high-strength wood-plastic composite material provided in this embodiment comprises the following steps:

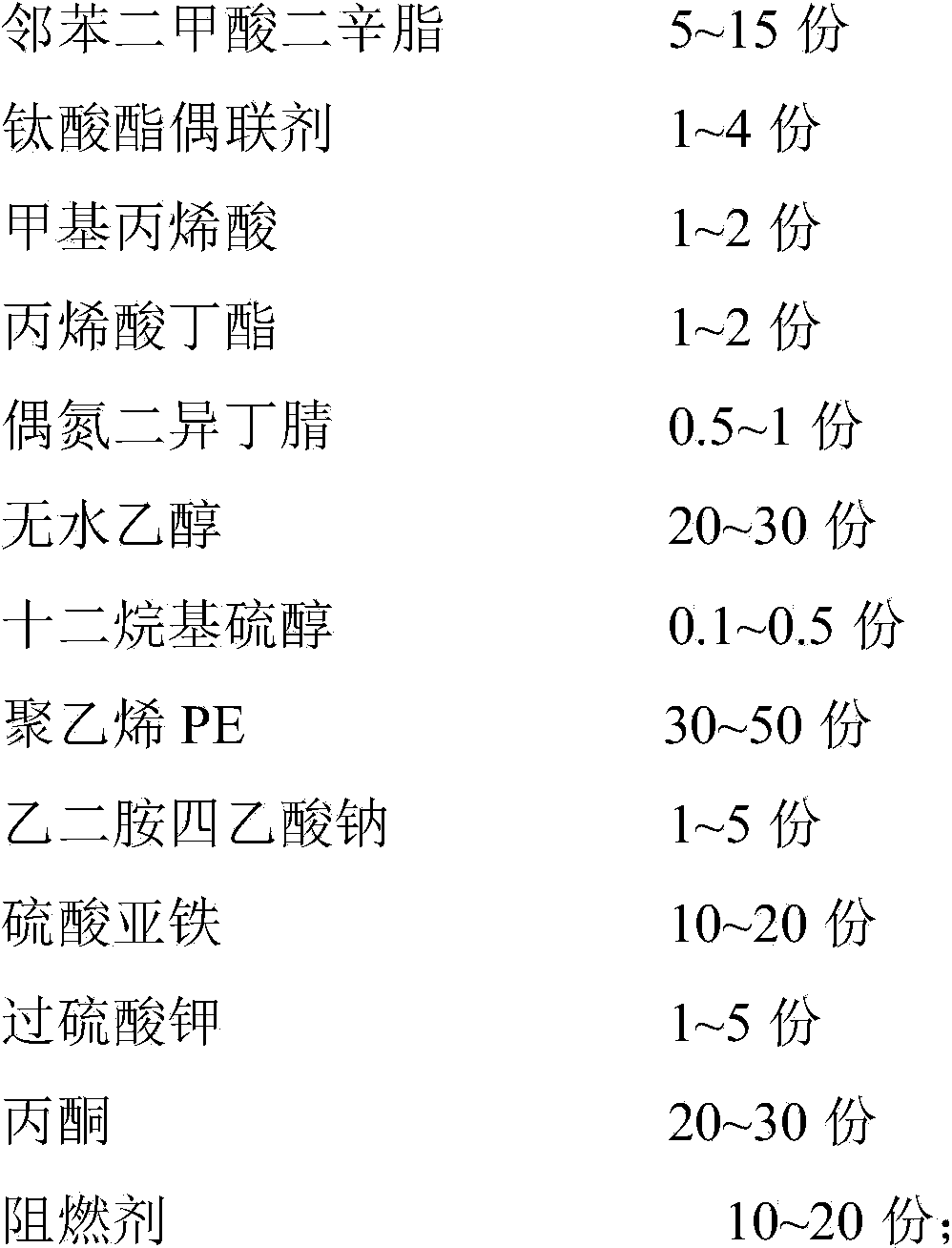

[0033] (1) prepare each component by following parts by weight:

[0034]

[0035]

[0036] Wherein said flame retardant is ammonium polyphosphate, one of melamine and dipentaerythritol;

[0037] (2) Dry the wood powder, and use the prepared titanate coupling agent to modify the surface of the dried wood powder to enhance its surface bonding performance;

[0038] Specifically, dry the wood powder in an electric blast drying oven at 120°C for 4 hours, degrease and dry it so that the moisture content is less than 0.2%, dilute the titanate coupling agent with acetone to 20% (V / V), then spray the diluted titanate coupling agent to treat the wood powder, and then add it to a high-speed mixer for pre-mixing for 0.5h, which can enhance its surface adhesion by more than 40%;

[0039] (3) with azobisisobutyronitrile and dod...

Embodiment 2

[0047] Example 2: The preparation method and product of high-strength wood-plastic composite material provided in this example, its steps and components are basically the same as those in Example 1, the difference is that it includes the following steps:

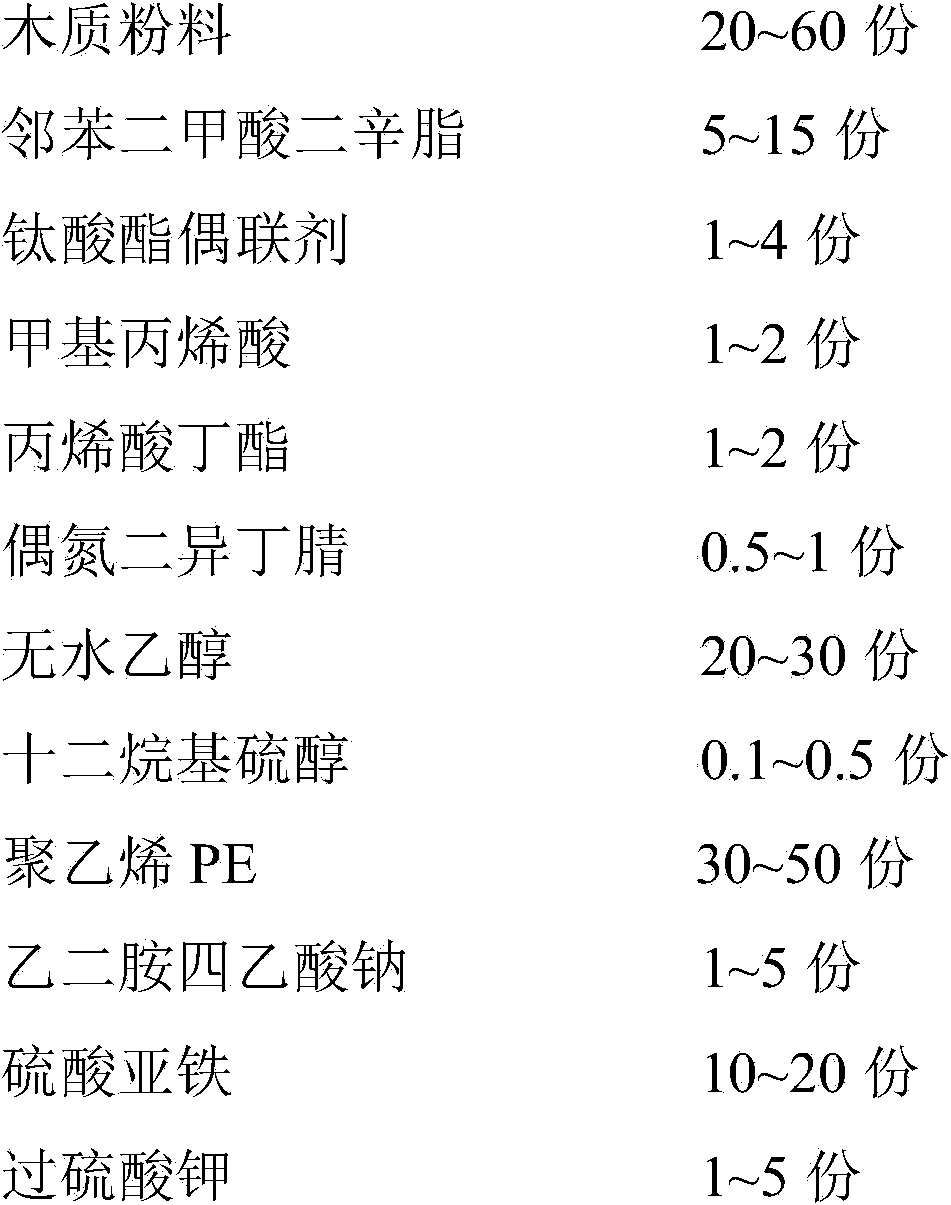

[0048] (1) prepare each component by following parts by weight:

[0049]

[0050]

[0051] (2) drying the wood powder, and using the prepared titanate coupling agent to modify the surface of the dried wood powder;

[0052] (3) with azobisisobutyronitrile and dodecyl mercaptan, methacrylic acid and butyl acrylate are carried out copolymerization reaction, obtain methacrylic acid, butyl acrylate copolymer;

[0053] (4) The modified wood powder, methacrylic acid, butyl acrylate copolymer, dioctyl phthalate, polyethylene PE, sodium edetate, ferrous sulfate, ammonium polyphosphate and peroxide Potassium sulfate was added to a high-speed mixer, and mixed for 5 minutes at a temperature of 80°C;

[0054] (5) Send the above-m...

Embodiment 3

[0058] Example 3: The preparation method and product of the high-strength wood-plastic composite material provided in this example, its steps and components are basically the same as those in Examples 1 and 2, the differences are:

[0059] A preparation method of high-strength wood-plastic composite material, comprising the following steps:

[0060] (1) prepare each component by following parts by weight:

[0061]

[0062]

[0063] (2) drying the wood powder, and modifying the dried wood powder with the prepared titanate coupling agent;

[0064] (3) with azobisisobutyronitrile and dodecyl mercaptan, methacrylic acid and butyl acrylate are carried out copolymerization reaction, obtain methacrylic acid, butyl acrylate copolymer;

[0065] (4) The modified wood powder, methacrylic acid, butyl acrylate copolymer, dioctyl phthalate, polyethylene PE, sodium edetate, ferrous sulfate, melamine and potassium persulfate , added to a high-speed mixer, and mixed for 8 minutes at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com