Preparing method for fine copper hydrophobic surface with wetting anisotropy

A super-hydrophobic surface, anisotropic technology, applied in the chemical field, can solve problems such as preparation difficulties, and achieve the effect of simple process, broad application prospects, and excellent anisotropic wetting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

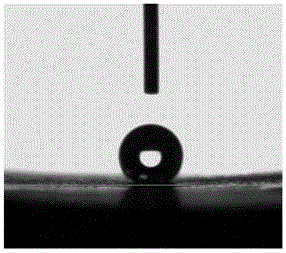

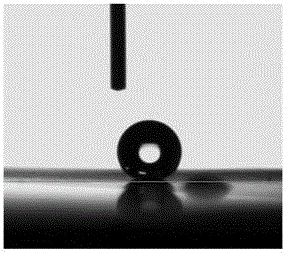

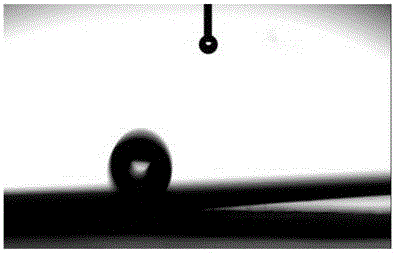

Image

Examples

Embodiment 1

[0040] A method for preparing a pure copper superhydrophobic surface with corrosion resistance, comprising the following steps:

[0041] A. Preparation of plating solution: Prepare copper sulfate solution with a concentration of 300g / L as the main component of the plating solution, and add ammonium nitrate with a concentration of 40g / L, citric acid with a concentration of 5g / L, and citric acid with a concentration of 5g / L. Hexadecyltrimethylammonium bromide, adsorbed by activated carbon to remove impurities, and filtered to obtain a clear and transparent plating solution;

[0042] B. Pretreatment of copper foil: Polish the pure copper through 400-mesh, 800-mesh and 1500-mesh metallographic sandpaper in turn to mirror effect, clean it ultrasonically in acetone solution for 10 minutes, and then use absolute ethanol and deionized water to clean it. Remove oil and grease on the surface of pure copper;

[0043] C. Physical etching: mechanically etch the pretreated copper foil with...

Embodiment 2

[0048] A method for preparing a pure copper superhydrophobic surface with corrosion resistance, comprising the following steps:

[0049] A, preparation of plating solution: preparation concentration is 300g / L copper sulfate solution as the main component of plating solution, and adding ammonium nitrate concentration is 40g / L of ammonium nitrate, concentration is the citric acid of 5g / L and concentration is 5g / L Cetyltrimethylammonium bromide, adsorbed by activated carbon to remove impurities, and filtered to obtain a clear and transparent plating solution;

[0050] B. Pretreatment of copper foil: Polish the pure copper through 400-mesh, 800-mesh and 1500-mesh metallographic sandpaper in turn to mirror effect, clean it ultrasonically in acetone solution for 10 minutes, and then use absolute ethanol and deionized water to clean it. Remove oil and grease on the surface of pure copper;

[0051] C. Physical etching: use the tip of a stainless steel knife to mechanically etch the p...

Embodiment 3

[0056] A, the preparation of plating solution: preparation concentration is that 300g / L copper sulfate solution is used as the main component of plating solution, and successively add the ammonium nitrate that concentration is 40g / L, the citric acid that concentration is 5g / L and the decathin that concentration is 5g / L Hexaalkyltrimethylammonium bromide, adsorbed by activated carbon to remove impurities, and filtered to obtain a clear and transparent plating solution;

[0057] B. Pretreatment of copper foil: Polish the pure copper through 400-mesh, 800-mesh and 1500-mesh metallographic sandpaper in turn to mirror effect, clean it ultrasonically in acetone solution for 10 minutes, and then use absolute ethanol and deionized water to clean it. Remove oil and grease on the surface of pure copper;

[0058] C. Physical etching: use the tip of a stainless steel knife to mechanically etch the parallel groove structure on the pretreated copper foil. The width of the groove is 100 μm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com