Method for preparing doublet acrylonitrile butadiene styrene (ABS) resin

A technology of ABS resin and small particle size, which is applied in the field of high-efficiency and easy-to-control bimodal ABS resin and its preparation, which can solve the problems of increasing the workload and time of the coagulation unit, and achieve the effect of improving the tensile strength and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

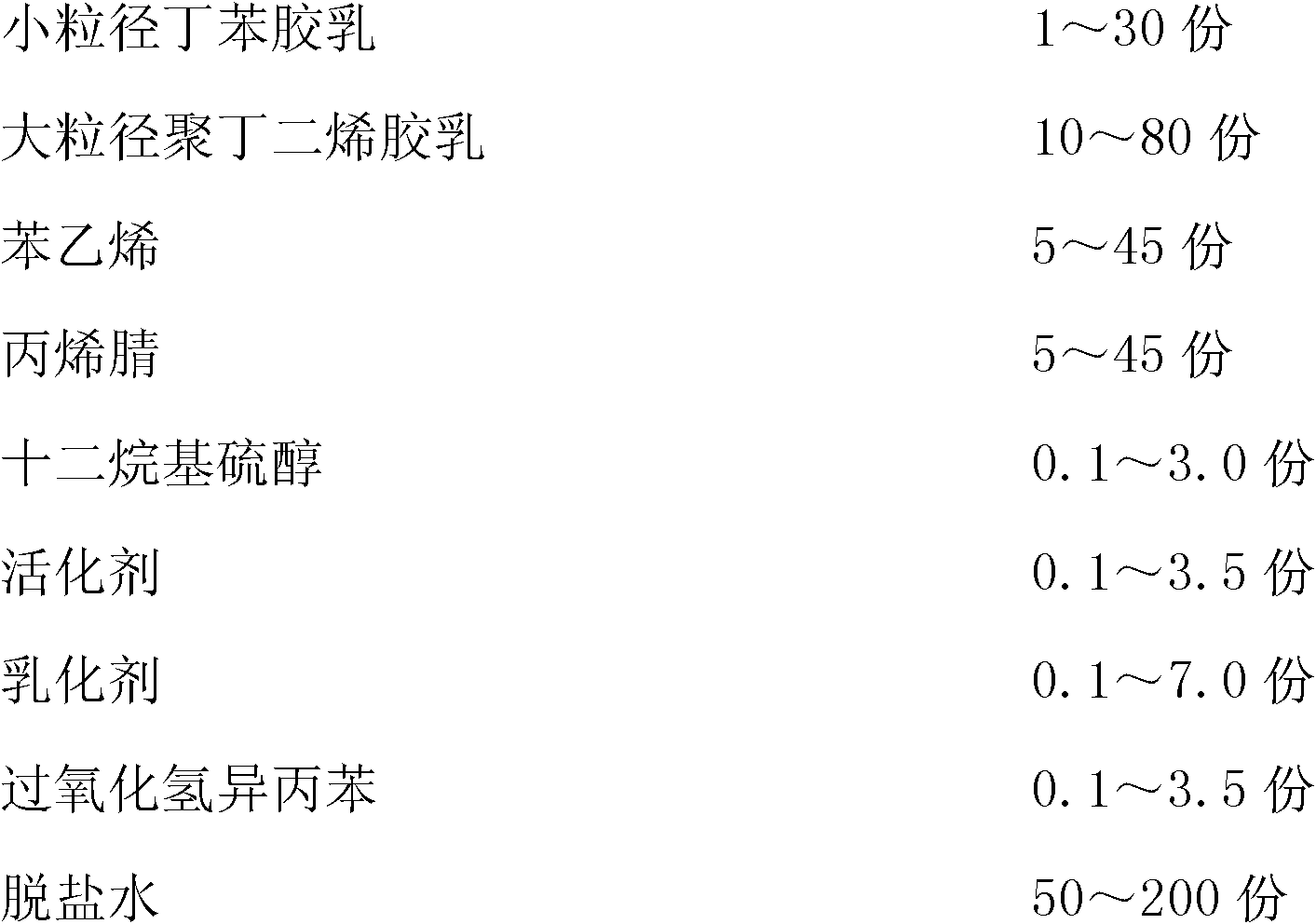

[0025] 1. ABS graft polymerization:

[0026] First, the small particle size styrene butadiene latex and the large particle size polybutadiene latex are fully stirred and mixed into the reactor, and then part of the emulsifier, styrene, acrylonitrile, dodecyl mercaptan, and desalinated water are added to the reactor. The temperature is controlled at 65°C. When the temperature rises to 48°C, add part of the activator and cumene hydroperoxide. After reacting for 1 hour, add the remaining emulsifier, styrene, and propylene within 2 hours by continuous feeding. Nitrile, dodecyl mercaptan, desalinated water, add the remaining activator and cumene hydrogen peroxide after the addition, and after aging for 0.8 hours, the reaction is over to obtain ABS latex;

[0027] 2. Filter the ABS latex obtained in 1 above with a 100-mesh white steel filter, add antioxidants, add 2 parts of concentrated sulfuric acid to the water, stir and heat, and control the temperature at 93°C for 15 minutes. The m...

Embodiment 2

[0037] 1. ABS graft polymerization:

[0038] First, the small particle size styrene butadiene latex and the large particle size polybutadiene latex are fully stirred and mixed into the reactor, and then part of the emulsifier, styrene, acrylonitrile, dodecyl mercaptan, and desalinated water are added to the reactor. The temperature is controlled at 40℃. When the temperature rises to 50℃, add part of the activator and cumene hydroperoxide. After reacting for 2 hours, add the remaining emulsifier, styrene and propylene within 3 hours by continuous feeding. Nitrile, dodecyl mercaptan, desalinated water, add the remaining activator and cumene hydrogen peroxide after the addition, and after curing for 1 hour, the reaction ends to obtain ABS latex;

[0039] 2. Filter the ABS latex obtained in 1 above with a 100 mesh white steel filter, add antioxidants, add 2.5 parts of concentrated sulfuric acid to the water, stir, heat, and control the temperature at 95°C for 15 minutes. The matured s...

Embodiment 3

[0049] 1. ABS graft polymerization:

[0050] First, the small particle size styrene butadiene latex and the large particle size polybutadiene latex are fully stirred and mixed into the reactor, and then part of the emulsifier, styrene, acrylonitrile, dodecyl mercaptan, and desalinated water are added to the reactor. The temperature is controlled at 80°C. When the temperature rises to 42°C, add part of the activator and cumene hydroperoxide. After 0.5 hours of reaction, add the remaining emulsifier, styrene, and propylene within 1 hour by continuous feeding Nitrile, dodecyl mercaptan, desalinated water, add the remaining activator and cumene hydrogen peroxide after the addition, and after maturing for 0.3 hours, the reaction is over to obtain ABS latex;

[0051] 2. Filter the ABS latex obtained in 1 above with a 100-mesh white steel filter, add antioxidants, add 2.0 parts of concentrated sulfuric acid to the water, stir, heat, and control the temperature at 94°C for 15 minutes. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com