Preparation method of high-fluidity amino molding plastic

An amino molding compound and high-fluidity technology, which is applied in the field of preparation of high-fluidity amino molding compounds, can solve problems such as cumbersome operations, increased equipment investment, etc., and achieve the effects of not easy fading and dyeing, and no loss of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

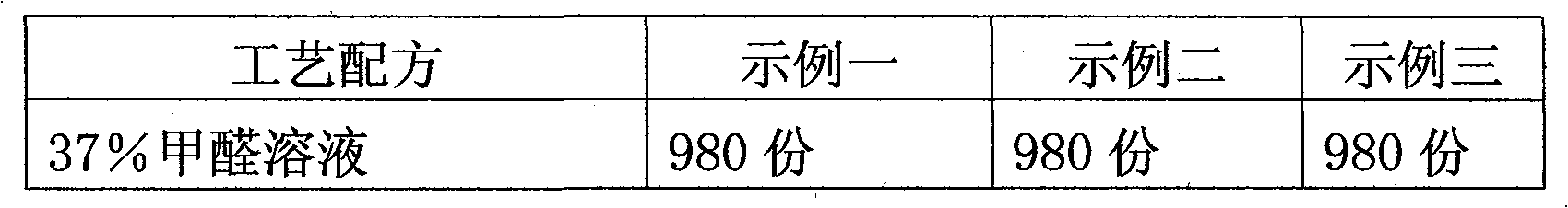

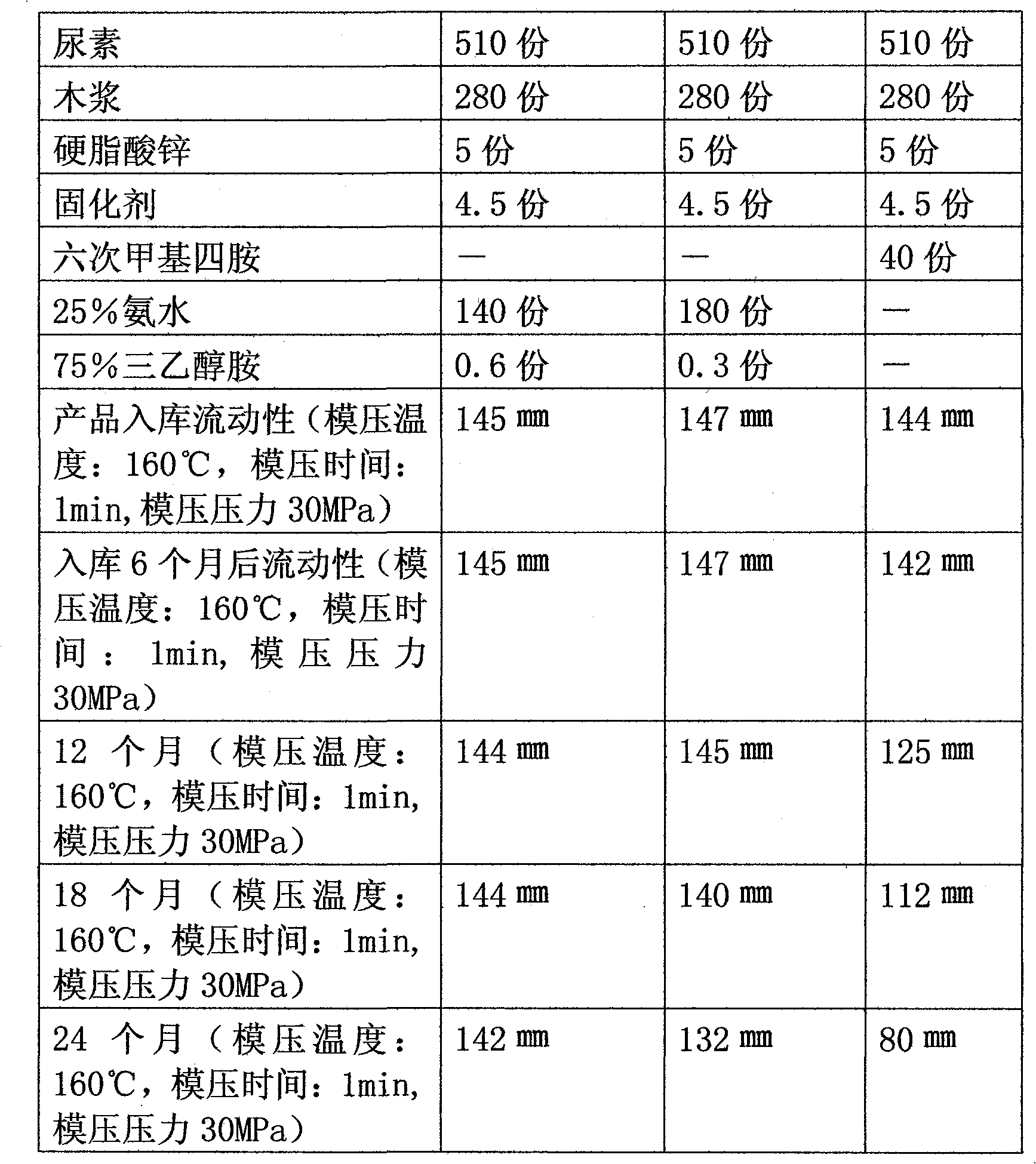

[0005] The present invention includes amino resin manufacturing-kneading-drying-pulverizing-amino molding compound, which is characterized in that in the manufacturing process of amino resin, a mixed solution of ammonia water and triethanolamine, or monoethanolamine, or diethanolamine is added, and 37% formaldehyde is added. Based on 1000 parts of the solution, the dosage of 25% ammonia water is between 80 and 250 parts, and the amount of triethanolamine is between 0.1 and 5 parts. Adjusting the ratio and total consumption of ammonia water and triethanolamine can effectively adjust the storage period of the product. The manufacturing method is as follows: adding 37% formaldehyde solution into the reactor after metering, adding 50% ammonia water in a quantitative proportion and stirring for 20 minutes, adding urea and warming up to 80 DEG C and stirring for 2 hours, and adding the remaining ammonia water and trihydrate when cooling to 60 DEG C. The compound of ethanolamine was s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com