A special water reducing agent for steel pipe jacking self-compacting concrete and preparation method thereof

A self-compacting concrete and steel pipe jacking technology is applied in the field of concrete admixtures, which can solve the problems of concrete divergence, increase in air content, and affect strength, and achieve the effects of supplementary shrinkage, low cost, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

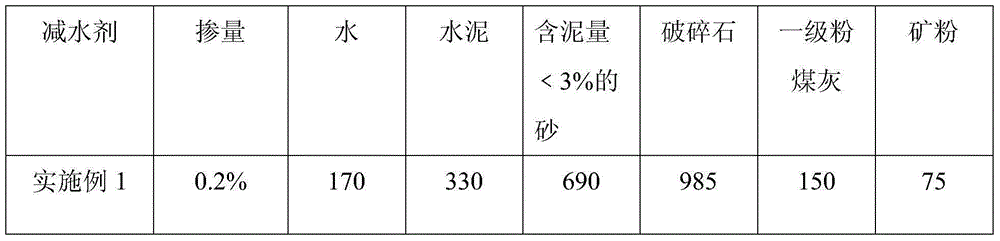

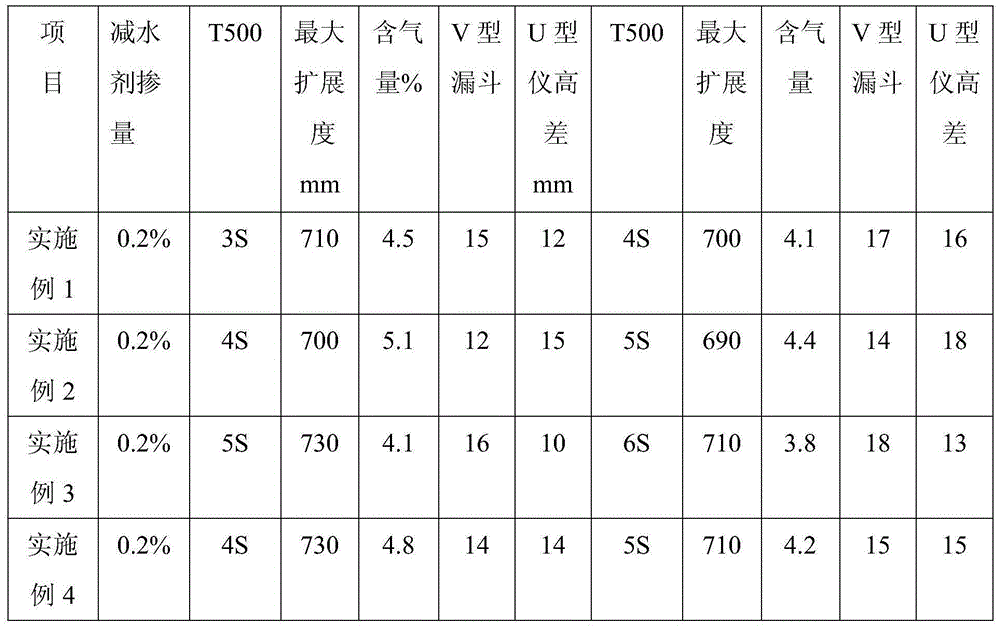

example 1

[0049]Add 160 parts of 40% Bote PVC-V polyester polycarboxylate water reducer to the mixing tank, then add 140 parts of 40% Feilong JML-8 polyether polycarboxylate water reducer, add 520 parts of water, open Stir, after stirring evenly, add 0.5 parts of bamboo oil AE-200 defoamer and stir for 10 minutes, add 30 parts of Hongye Kyushu M2 tackifier, 120 parts of sodium nitrite, 53 parts of sodium gluconate and continue stirring for 20 minutes, After adding 4 parts of AFK-2 air-entraining agent and stirring for 10 minutes, product 1 was obtained.

example 2

[0051] Add 180 parts of 40% Bote PVC-IV polyester polycarboxylate water reducer to the mixing tank, then add 120 parts of 40% Weiding WD-2 polyether polycarboxylate water reducer, add 540 parts of water, Turn on the stirring, after stirring evenly, add 0.5 parts of catalyst SFL-1 defoamer and stir for 10 minutes, add 30 parts of Hongye Kyushu M2 tackifier, 100 parts of sodium nitrite, 53 parts of sodium gluconate and continue stirring for 20 minutes, Add 4 parts of Tiejian Shengjie TJ-2 air-entraining agent and stir for 10 minutes to obtain product 2.

example 3

[0053] Add 200 parts of 40% Bangford SS-100 polyester polycarboxylate superplasticizer to the mixing tank, then add 140 parts of 40% Bott PVC-II polyether polycarboxylate superplasticizer, add 520 parts of water , turn on the stirring, after stirring evenly, add 0.5 parts of AE-200 defoamer and stir for 10 minutes, add 30 parts of Tiejian Shengjie TJZ-1 viscosity increaser, 80 parts of sodium nitrite, 51 parts of sodium gluconate and continue stirring for 20 minutes Finally, add 6 parts of Tiejian Shengjie TJ-1 air-entraining agent and stir for 10 minutes to obtain product 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com