Method for preparing nano copper powder

A technology of nano copper powder and copper sulfate, applied in the field of electrochemical preparation of nano copper powder, can solve the problems such as difficulty in maintaining stability of dispersion liquid for a long time, adverse effects on sintering performance, limited application scope, etc., and achieves low cost, small particle size, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

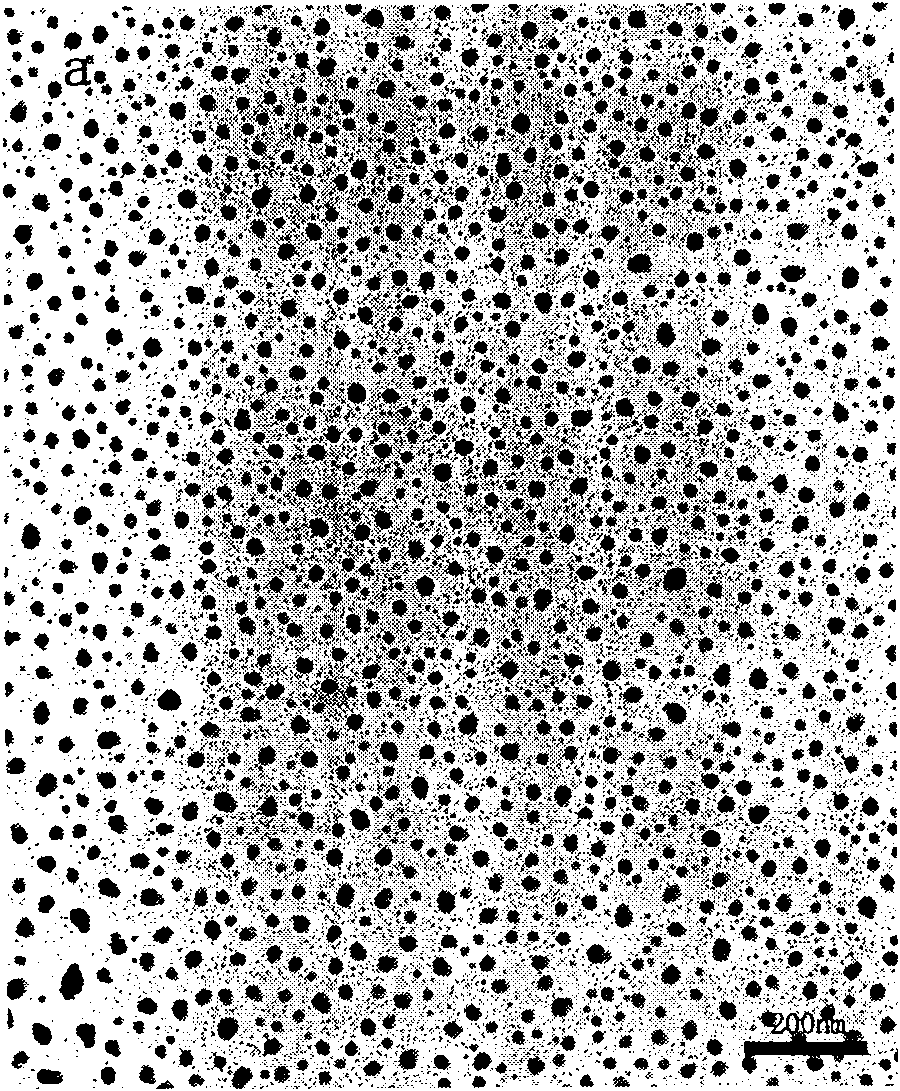

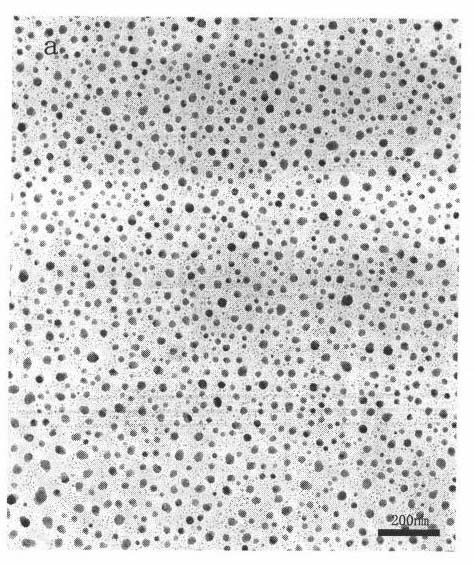

Image

Examples

preparation example Construction

[0013] The present invention is a kind of preparation method of nanometer copper powder, and its steps are:

[0014] (1) The molar ratio of copper sulfate, sodium lauryl sulfate and polyoxyethylene sorbitan monooleate is 1: 0.5~2: 0.05~0.3, dissolved in water, and mixed with sulfuric acid The molar ratio of copper to dodecyl mercaptan is 1: 0.5~2 The above-mentioned aqueous solution is mixed with the benzene solution containing dodecyl mercaptan, and stirred evenly under the action of a magnetic stirrer and ultrasonic waves;

[0015] (2) Inject the evenly stirred emulsion into the electrolytic cell, use pure copper as the anode, stainless steel as the cathode, the area ratio of the anode and the cathode is 1:2-5, and the distance between the pole pieces is 30-70mm. The pH value is adjusted to 0.5-4;

[0016] (3) Direct current is applied to the electrode, so that the copper of the anode is continuously dissolved into the electrolyte, and the copper ions in the solution near t...

Embodiment 1

[0020] Take 5 g of anhydrous copper sulfate and dissolve it in 500 mL of distilled water.

[0021] Take 1 g of sodium lauryl sulfate, 5 mL of Tween 80, 15 mL of dodecyl mercaptan, and 20 mL of benzene, and stir evenly under the action of a magnetic stirrer and ultrasonic waves.

[0022] The above two solutions were mixed, mixed evenly under the action of a magnetic stirrer, and titrated with concentrated sulfuric acid until the pH value was 0.5.

[0023] The prepared emulsion is used as electrolyte, pure copper is used as anode, stainless steel mesh is used as cathode, the area ratio of anode and cathode is 1:2, the distance between pole pieces is 30mm, and the current density of cathode is 0.01A / cm 2 , direct current is applied to the electrode, so that the copper in the anode is continuously dissolved into the electrolyte, and the copper ions in the solution near the cathode are continuously precipitated and deposited on the cathode, and the dodecyl mercaptan dissolved in th...

Embodiment 2

[0026] Take 12.5 g of anhydrous copper sulfate and dissolve it in 500 mL of distilled water.

[0027] Take 1 g of sodium lauryl sulfate, 5 mL of Tween 80, 15 mL of dodecyl mercaptan, and 20 mL of benzene, and stir evenly under the action of a magnetic stirrer and ultrasonic waves.

[0028] The above two solutions were mixed, mixed evenly under the action of a magnetic stirrer, and titrated with concentrated sulfuric acid until the pH value was 4.

[0029] The prepared emulsion is used as electrolyte, pure copper is used as anode, stainless steel mesh is used as cathode, the area ratio of anode and cathode is 1:5, the distance between pole pieces is 45mm, and the current density of cathode is 0.2A / cm 2 , direct current is applied to the electrode, so that the copper in the anode is continuously dissolved into the electrolyte, and the copper ions in the solution near the cathode are continuously precipitated and deposited on the cathode, and the dodecyl mercaptan dissolved in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com