Nano C-S-H seed crystal early strength agent for building concrete and preparation method thereof

A C-S-H, concrete technology, applied in the field of concrete additives, can solve the problems affecting the quality and quality of concrete components, and achieve the effects of no electrochemical corrosion phenomenon, accelerated reaction process, and no influence on later strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

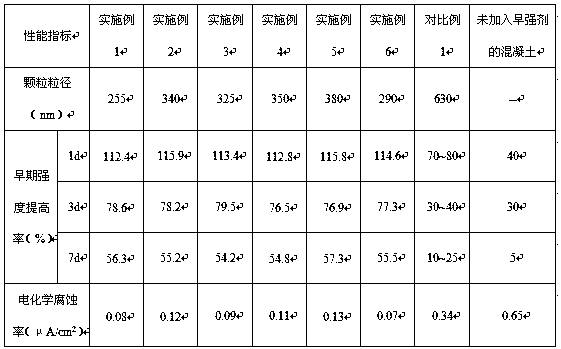

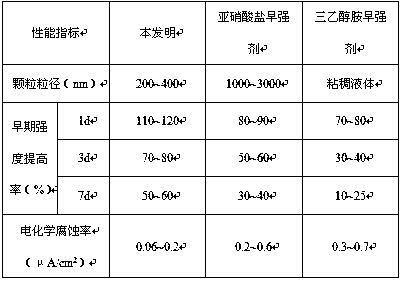

Examples

Embodiment 1

[0032] (1) Add acrylic monomers, silane coupling agent, and modified polyoxyethylene ether to the redox system composed of ammonium persulfate, vitamin C and dodecyl mercaptan, and obtain a molecular weight of 10,000 by polymerization reaction High molecular polymer and formulated into polymer solution; acrylic monomers are acrylic acid and methacrylic acid; silane coupling agent is vinyl trimethoxysilane; modified polyoxyethylene ether is allyl alcohol polyoxyethylene ether ( APEG); The mass concentration of the polymer solution is 16%;

[0033] In the reaction system, in parts by weight: 36 parts of acrylic monomer, 4 parts of silane coupling agent, 13 parts of modified polyoxyethylene ether, 3 parts of ammonium persulfate, 4 parts of vitamin C, and dodecyl mercaptan 40 copies;

[0034] (2) Prepare sodium metasilicate into solution A with a mass concentration of 48%, and calcium nitrate into solution B with a mass concentration of 35%;

[0035] (3) Place the polymer solution prep...

Embodiment 2

[0038] (1) Add acrylic monomer, silane coupling agent, and modified polyoxyethylene ether into the redox system composed of ammonium persulfate, vitamin C and dodecyl mercaptan, and obtain a molecular weight of 4000 by polymerization reaction High molecular polymer and formulated into polymer solution; acrylic monomer is methacrylic acid; silane coupling agent is vinyl triethoxy silane; modified polyoxyethylene ether is prenol polyoxyethylene ether ( TPEG); The mass concentration of the polymer solution is 12%;

[0039] In the reaction system, in parts by weight: 30 parts of acrylic monomer, 3 parts of silane coupling agent, 11 parts of modified polyoxyethylene ether, 2 parts of ammonium persulfate, 3 parts of vitamin C, and dodecyl sulfide 49 parts of alcohol;

[0040] (2) Prepare sodium metasilicate into solution A with a mass concentration of 45%, and calcium nitrate into solution B with a mass concentration of 30%;

[0041] (3) Place the polymer solution prepared in step (1) on...

Embodiment 3

[0044] (1) Add acrylic monomer, silane coupling agent, and modified polyoxyethylene ether into the redox system composed of ammonium persulfate, vitamin C and dodecyl mercaptan, and obtain a molecular weight of 20,000 by polymerization reaction High molecular polymer and formulated into polymer solution; acrylic monomer is methyl acrylate; silane coupling agent is γ-aminopropyl triethoxysilane; modified polyoxyethylene ether is polyethylene glycol monomethyl Ether (MPEG); the mass concentration of the polymer solution is 20%;

[0045] In the reaction system, in parts by weight: 42 parts of acrylic monomer, 5 parts of silane coupling agent, 15 parts of modified polyoxyethylene ether, 4 parts of ammonium persulfate, 5 parts of vitamin C, and dodecyl sulfide 31 parts of alcohol;

[0046] (2) Sodium metasilicate is formulated into solution A with a mass concentration of 50%, and calcium nitrate is formulated into solution B with a mass concentration of 40%;

[0047] (3) Place the polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com