Preparation of acrylate polymer emulsion with gradient network structure for pressure-sensitive adhesive

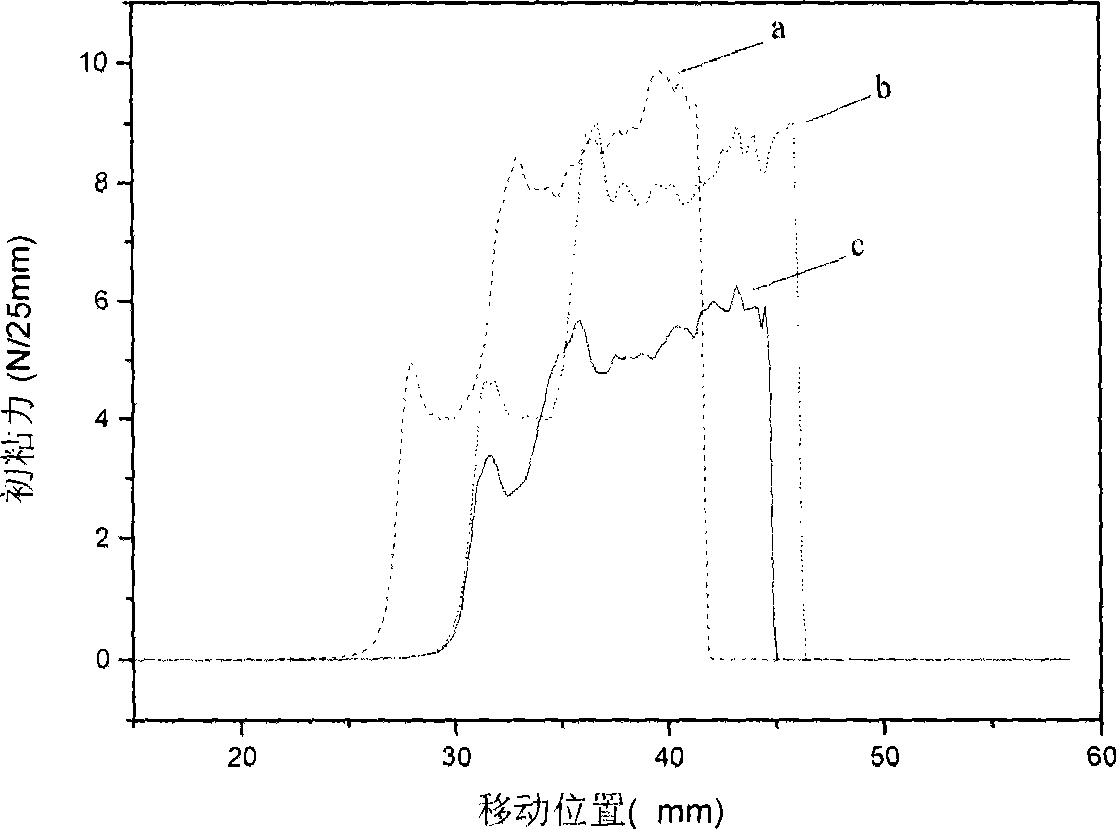

A technology of polymer emulsion and gradient structure, applied in the direction of ester copolymer adhesives, adhesive types, etc., to achieve the effect of improving initial adhesion, large peeling force and holding force, and high conversion rate of reaction monomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of network gradient structure acrylate polymer emulsion for pressure-sensitive adhesive comprises the following steps:

[0025] ①Preparation of seed emulsion: at 83°C, in a polymerization container, dissolve 0.4g of emulsifier diisooctyl sulfonate sodium succinate in 140g of water evenly, then add 10g of butyl acrylate and stir for 10 minutes, then add 20g of mass ratio Polymerization was initiated for 2% initiator potassium persulfate solution for 1 h.

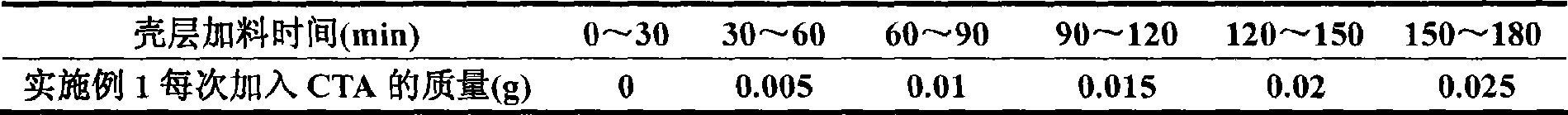

[0026] ② Pre-emulsification of the shell monomer: Mix 2.18g of emulsifier diisooctyl sulfonate sodium with 185.25g of butyl acrylate and 4.75g of acrylic acid, and take out 95.925g of the mixed solution and 0.075g of chain transfer agent tertiary After dodecyl mercaptan is mixed evenly, it is divided into 6 parts according to n×6.4g, n=0, 1, 2, 3, 4, 5, and it is mixed with the above mixed solution without chain transfer agent respectively, Six pre-emulsions of equal mass were formed, each pre-emulsion...

Embodiment 2~3

[0044] Preparation;

[0045] 1. the preparation of seed emulsion: with embodiment 1.

[0046] ② Pre-emulsification of the shell monomer: Mix 2.18g of emulsifier diisooctyl sulfonate sodium with 185.25g of butyl acrylate and 4.75g of acrylic acid, and take out 95.925g of the mixed solution and 0.075g of chain transfer agent tertiary Dodecyl mercaptan is uniformly mixed according to n × 6.4g, n is 5, 4, 3, 2, 1, 0 (for Example 2) or n=2.5, 2.5, 2.5, 2.5, 2.5, 2.5 (for Embodiment 3) is divided into 6 parts, and it is respectively mixed with the mixed solution that does not add chain transfer agent above, forms 6 parts of pre-emulsion, and the quality of every part of pre-emulsion is 32.043g. The mass of tert-dodecyl mercaptan in each part of pre-emulsion gradually increases, that is, positive gradient, and the quality of tert-dodecyl mercaptan in each part of pre-emulsion is constant, that is, uniform. Table 2 shows the change of tert-dodecylmercaptan quality over time during g...

Embodiment 4~6

[0052] Preparation:

[0053] 1. the preparation of seed emulsion: with embodiment 1.

[0054] ② Pre-emulsification of the shell monomer: Mix 2.18g of emulsifier diisooctyl sulfonate sodium with 185.25g of butyl acrylate and 4.75g of acrylic acid, and take out 95.85g of the mixed solution and 0.15g of chain transfer agent tert- Dodecyl mercaptan is uniformly mixed according to n × 6.4g, n is 0, 1, 2, 3, 4, 5 (for Example 4) or n is 5, 4, 3, 2, 1, 0 (for Embodiment 5) or n=2.5, 2.5, 2.5, 2.5, 2.5, 2.5 (being embodiment 6) is divided into 6 parts, and it is mixed with the mixed solution that does not add chain transfer agent above respectively, forms 6 parts of preliminary Emulsion, the mass of each pre-emulsion is 32.055g. Table 3 shows the change of tertiary dodecyl mercaptan quality with time during gradient feeding in Examples 4-6.

[0055] ③Shell layer gradient feeding: At 83°C, first add 10 g of initiator potassium persulfate solution with a mass ratio of 0.9% to 170.4 g...

PUM

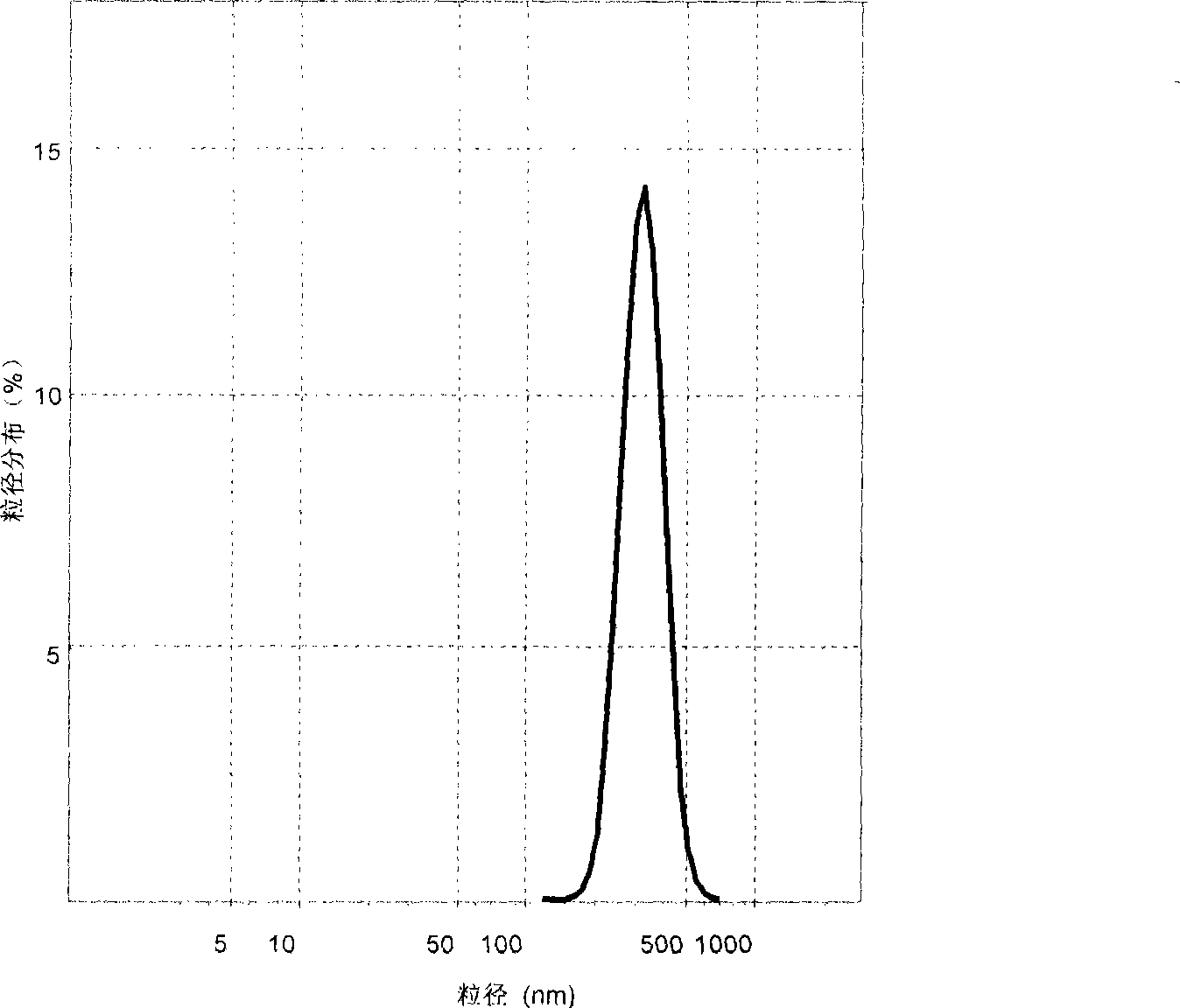

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com