Flotation separation agent system for copper-molybdenum mixed concentrates and application of flotation separation agent system

A technology of copper-molybdenum mixed concentrate and mixed concentrate, which is applied in flotation, solid separation, etc., can solve the problems of poor concentrate products and low separation efficiency of copper-molybdenum mixed concentrate, achieve excellent results, and avoid floatability Decrease and increase the effect of planktonic difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

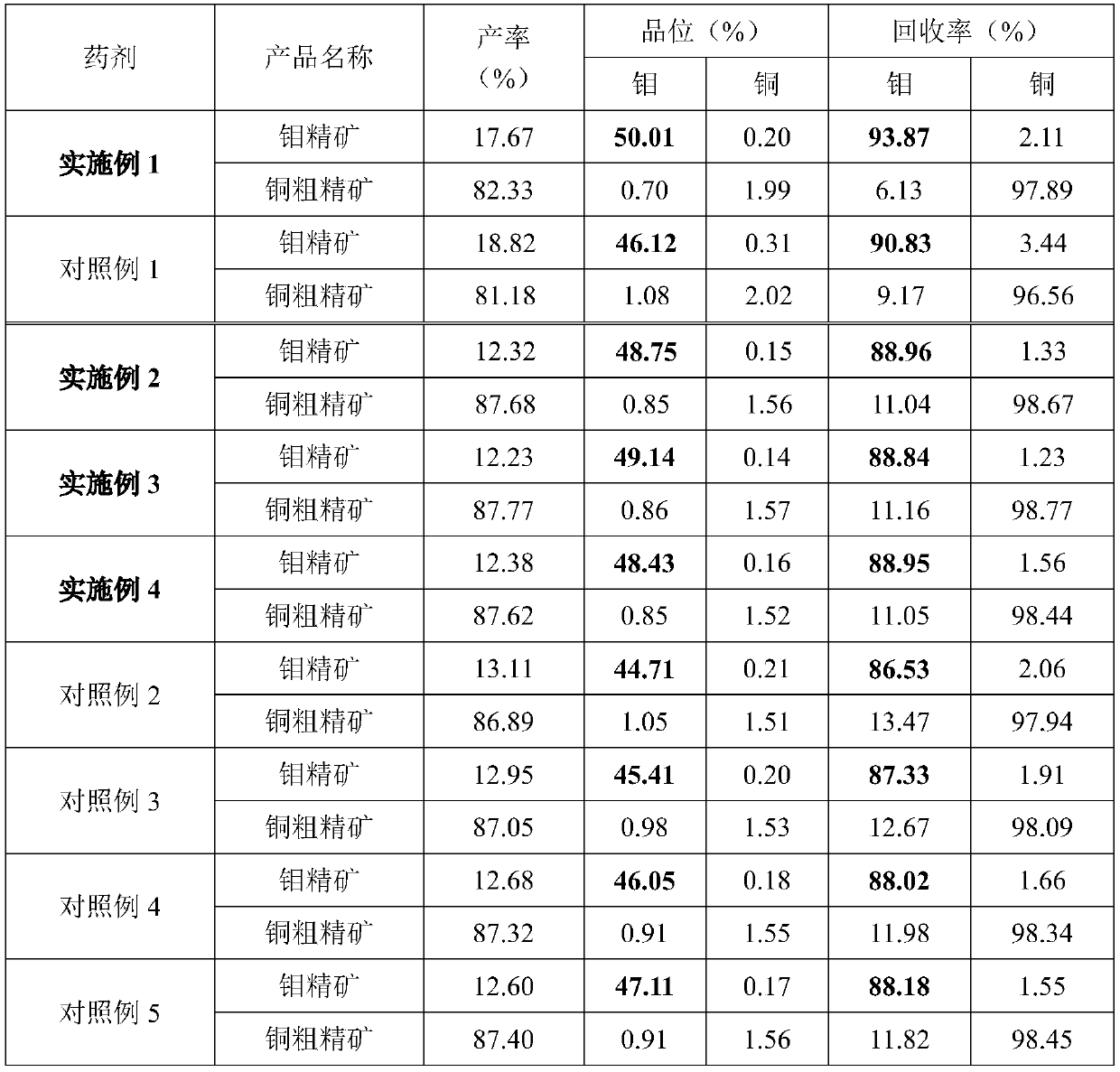

Examples

Embodiment 1

[0028] 1. Drug preparation

[0029] Copper mineral inhibitors and molybdenum mineral collectors were prepared respectively, wherein the copper mineral inhibitors were prepared from the following components: 7 parts of sodium hydroxide, 5 parts of hydrogen peroxide, 25 parts of sodium thioglycolate, diethylene triethylene 4 parts of pentasodium aminepentaacetic acid, 200 parts of water; the molybdenum mineral collector is composed of the following components: 25 parts of kerosene, 8 parts of tertiary dodecyl mercaptan; the foaming agent is 2-hexanol.

[0030] 2. Drug application method

[0031] The copper-molybdenum mixed concentrate used is taken from a molybdenum beneficiation plant in Shaanxi. The grade of molybdenum in the mixed concentrate is 9.40%, and the grade of copper is 1.68%. The fineness of the mixed concentrate is -74μm and the content is 70%-72%. Mix the mixed concentrate and dry it in the shade, then pack it into bags and seal it for later use. Using the above...

Embodiment 2

[0037] 1. Drug preparation

[0038] Copper mineral inhibitors and molybdenum mineral collectors were prepared respectively, wherein the copper mineral inhibitors were prepared from the following components: 4 parts of sodium hydroxide, 3 parts of hydrogen peroxide, 20 parts of sodium thioglycolate, diethylene triethylene 2 parts of pentasodium aminepentaacetic acid, 150 parts of water; the molybdenum mineral collector is composed of the following components: 25 parts of kerosene, 6 parts of tert-dodecylmercaptan; the foaming agent is 2-hexanol.

[0039] 2. Drug application method

[0040] The copper-molybdenum mixed concentrate used is taken from a molybdenum beneficiation plant in Henan. The grade of molybdenum in the mixed concentrate is 6.75%, and the grade of copper is 1.32%. The fineness of the mixed concentrate is -74μm and the content accounts for 73%-75%. Mix the mixed concentrate and dry it in the shade, then pack it into bags and seal it for later use. Using the ab...

Embodiment 3

[0046] The copper-molybdenum mixed concentrate and beneficiation steps adopted in this embodiment are all the same as those in Example 2, the difference lies in the composition ratio of copper mineral inhibitors and molybdenum mineral collectors and the separation and roughing of copper and molybdenum, molybdenum sweeping, molybdenum The amount of medicine used in the selection step is different; the proportion of medicine ingredients and the medicine content of each step are respectively:

[0047] Ratio of pharmaceutical ingredients: Copper mineral inhibitor is prepared from 3 parts of sodium hydroxide, 3 parts of hydrogen peroxide, 15 parts of sodium thioglycolate, 2 parts of pentasodium diethylenetriaminepentaacetic acid, and 150 parts of water, molybdenum minerals are collected 20 parts of kerosene, 5 parts of tert-dodecylmercaptan, and 2-hexanol as foaming agent;

[0048] Copper-molybdenum mixed concentrate grinding: Add 150 g / ton of sodium hydroxide to the mixed concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com