Inhibitor-free floatation separation method for high-sulfur copper and zinc sulphide ore difficult to float

A technology without inhibitors and separation methods, applied in flotation, solid separation, etc., can solve the problems of chemical waste, toxicity, and environmental impact, and achieve the effects of easy control, less mutual content, and effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

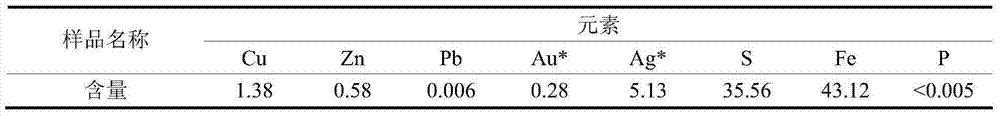

[0056] The method of the present invention was used to conduct a beneficiation test study on a high-sulfur copper-zinc sulfide ore in Qinghai. The elemental analysis of the raw ore is shown in Table 1.

[0057] Table 1 Analysis results of raw ore elements / %

[0058]

[0059]

[0060] *g / t

[0061] As can be seen from the data in Table 1, the main metal elements recyclable in this mine are Cu and Zn. According to the properties of the raw ore, the process of the present invention is adopted. The specific process flow is shown in the appendix figure 1 . Mainly:

[0062] (1) Prioritize copper selection to obtain qualified copper concentrate;

[0063] (2) Re-select zinc to obtain qualified zinc concentrate.

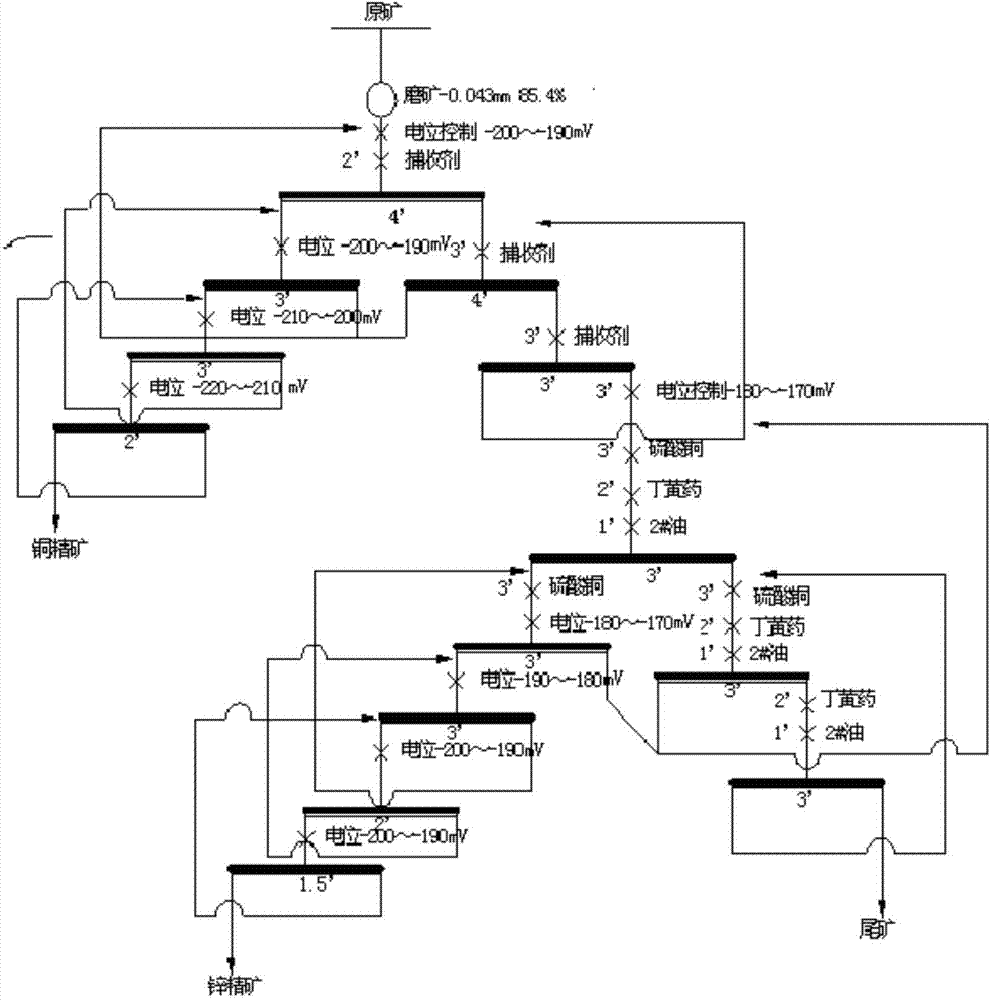

[0064] as attached figure 1 As shown, the ore is ground first, and the number of ore particles with a diameter of no more than 0.043mm accounts for 85.40% of the total, and then flotation separation is carried out, and the copper selection step is given priority, a...

Embodiment 2

[0072] Adopt the inventive method to carry out copper-zinc separation to above-mentioned ore adopting MA / butyroxanthate combined collector, concrete technological process is as attached figure 1 Shown:

[0073] Grind the ore first, and the number of ore particles with a diameter of no more than 0.043mm accounts for 85.40% of the total, and then carry out flotation separation, giving priority to the copper selection step, roughing and adding lime to adjust the slurry potential -200 ~ -190mV, adding MA (produced by Hubei Jingjiang Mineral Dressing Chemicals Co., Ltd.) / butadiene xanthate combination collector, the dosage is 24 / 24g / t; the coarse concentrate is selected for 3 times, and only lime is added to adjust the pulp potential for each selection. The slurry potential is controlled at -200~-190mV for the selection; the slurry potential is -210~-200mV for the second selection; the slurry potential is -220~-210mV for the third selection; Add different amounts of MA / Dxanthate c...

Embodiment 3

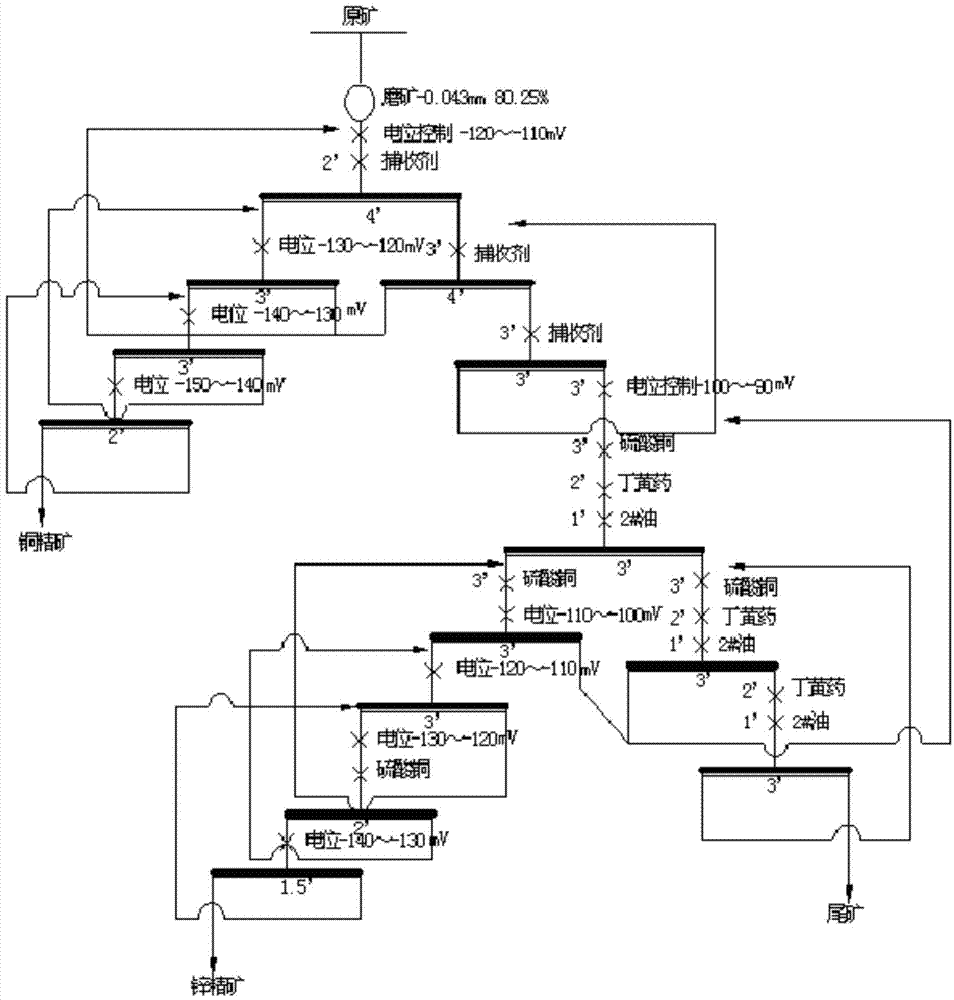

[0081] Adopt the inventive method to carry out on-the-spot test to above-mentioned ore adopting MA / butyroxanthate combination collector, and raw ore element analysis is shown in Table 4, and concrete technological process is as attached figure 2 Shown:

[0082] Table 4 Results of multi-element analysis of raw ore / %

[0083]

[0084] *g / t

[0085] Since the concentrator is located on a plateau at an altitude of 4,200 meters, the air is thin and the oxygen content is low, only 0.6 atmospheres. Therefore, the corresponding parameters need to be adjusted accordingly, as follows:

[0086] Grind the ore first, and the number of ore particles with a diameter of no more than 0.043mm accounts for 80.25% of the total, and then carry out flotation separation, giving priority to the copper selection step, roughing and adding lime to adjust the slurry potential -120 ~ -110mV, adding MA xanthate combined collector, the dosage is 35 / 35g / t; the coarse concentrate is beneficiated for 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com