Combined inhibitor for flotation separation of complex refractory copper-lead sulfide ore and application of combined inhibitor

A technology of combining inhibitors and sulfide ore, applied in the directions of flotation, solid separation, process efficiency improvement, etc., can solve the problems of environmentally harmful sodium sulfite, can not meet the non-toxic environmental protection and other problems, and achieves low consumption of chemicals and good industrial application prospects , the effect of strengthening the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

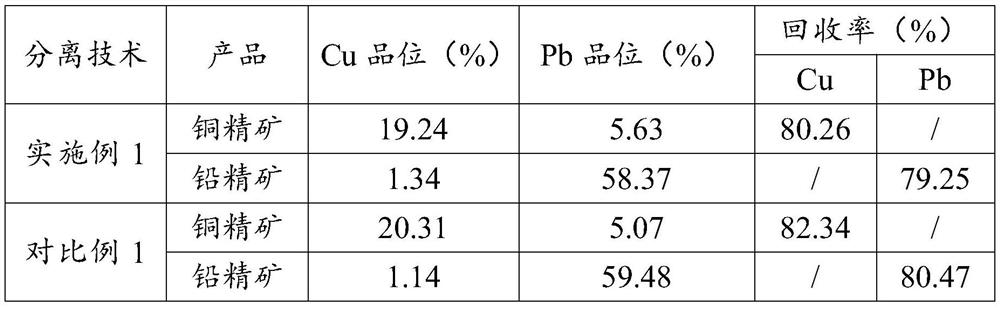

Embodiment 1

[0026] Taking a copper-lead polymetallic sulfide mine in Yunnan as the object, the raw ore contains 0.28% Cu and 2.98% Pb, the main ore minerals are chalcopyrite, galena, sphalerite, and the main gangue minerals are calcite, quartz, Potassium feldspar, etc.;

[0027] In this example, the combination inhibitor of galena was added together with a mass concentration of 5% sodium perborate solution, 0.5% quaternary ammonium starch ether solution and 0.5% hydroxypropyl methylcellulose solution, and the addition ratio was 1:1.5: 2.5;

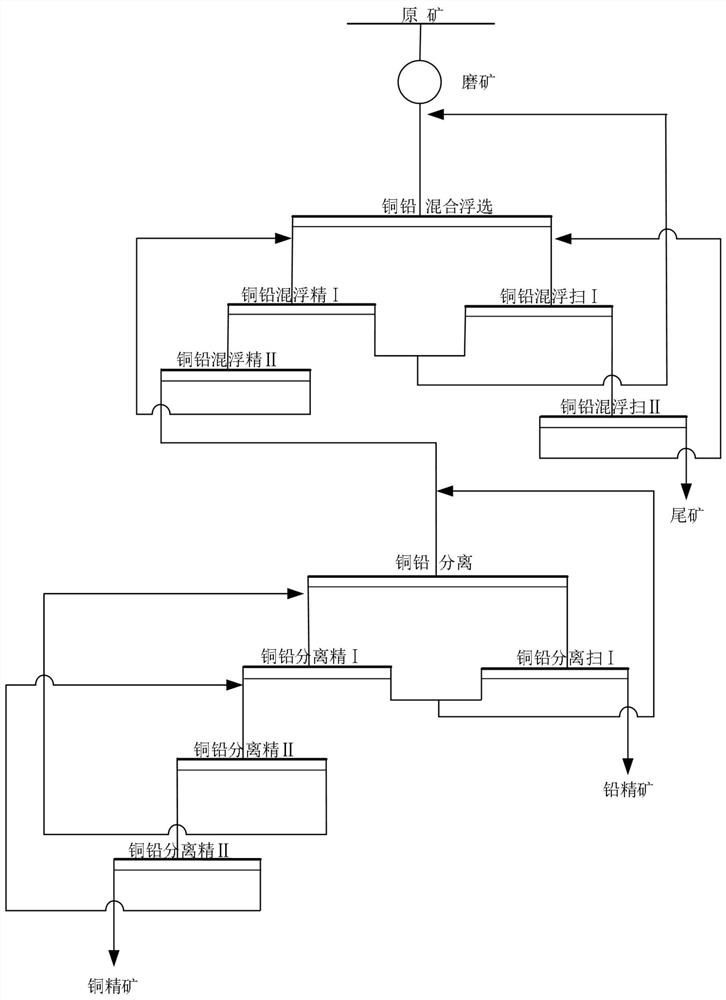

[0028] see figure 1 Shown, a kind of combined depressant that is used for the flotation separation of complex refractory copper-lead sulfide ore is used for the flotation separation of copper-lead sulfide ore, comprises the following steps:

[0029] S1, crush the raw ore taken to -2mm, and then grind the crushed ore finely until the particle size of the ore particles is -0.074mm, accounting for 75%, add water to adjust the slurry, so that the concen...

Embodiment 2

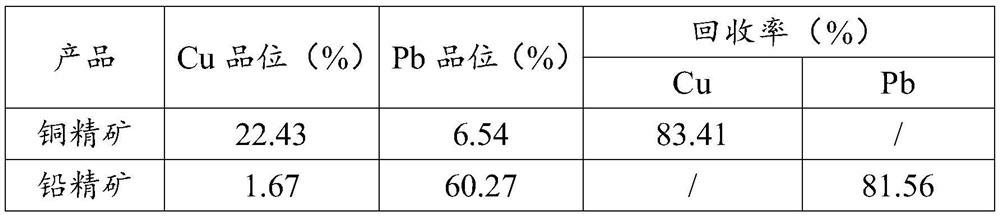

[0044] Taking a copper-lead metal sulfide mine in Sichuan as an example, the raw ore contains 0.45% Cu and 3.24% Pb, copper mainly exists in the form of chalcopyrite, lead mainly exists in the form of galena, and the embedded particle size is relatively fine;

[0045] In this example, the galena combined inhibitor is added together with a mass concentration of 5% sodium perborate solution, 0.5% quaternary ammonium starch ether solution and 0.5% hydroxypropyl methylcellulose solution, and the addition ratio is 1.5:2: 2.5; Compared with Example 1, the only difference is that the combined inhibitor dosage in the roughing process in step S3 is 600g / t, and other steps are basically the same as those in Example 1, so they will not be repeated here. Flotation separation The results are shown in Table 2.

[0046] Copper-lead mixed concentrate flotation separation result in table 2 embodiment 2

[0047]

[0048] As can be seen from the test results in Table 2, the application of th...

Embodiment 3

[0050] Taking a copper-lead metal sulfide mine in Hunan as an example, the raw ore contains 0.19% Cu and 2.37% Pb, the copper mainly occurs in chalcopyrite, and the lead mainly occurs in galena;

[0051] In this example, the combination inhibitor of galena was added together with a mass concentration of 5% sodium perborate solution, 0.5% quaternary ammonium starch ether solution and 0.5% hydroxypropyl methylcellulose solution, and the addition ratio was 1:2: 3; Compared with Example 1, the difference is only: add water glass 1200g / t in the rough selection process in step S2, add activated carbon 3000g / t in the rough selection process in step S3, combined inhibitor 800g / t, the first 250 g / t of combined inhibitors were added to the first selection, and 150 g / t of combined inhibitors were added to the second selection. The other steps were basically the same as those in Example 1, and will not be repeated here. The results of flotation separation are shown in Table 3.

[0052] Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com