Method for recycling copper aluminum and rubber in waste power lithium battery

A lithium battery, copper-aluminum technology, applied in the field of lithium battery recycling, can solve the problems of reduced product sales value, large mutual inclusion of copper and aluminum products, and reduced product purity, so as to achieve high sales economic income and low mutual inclusion of copper and aluminum products , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

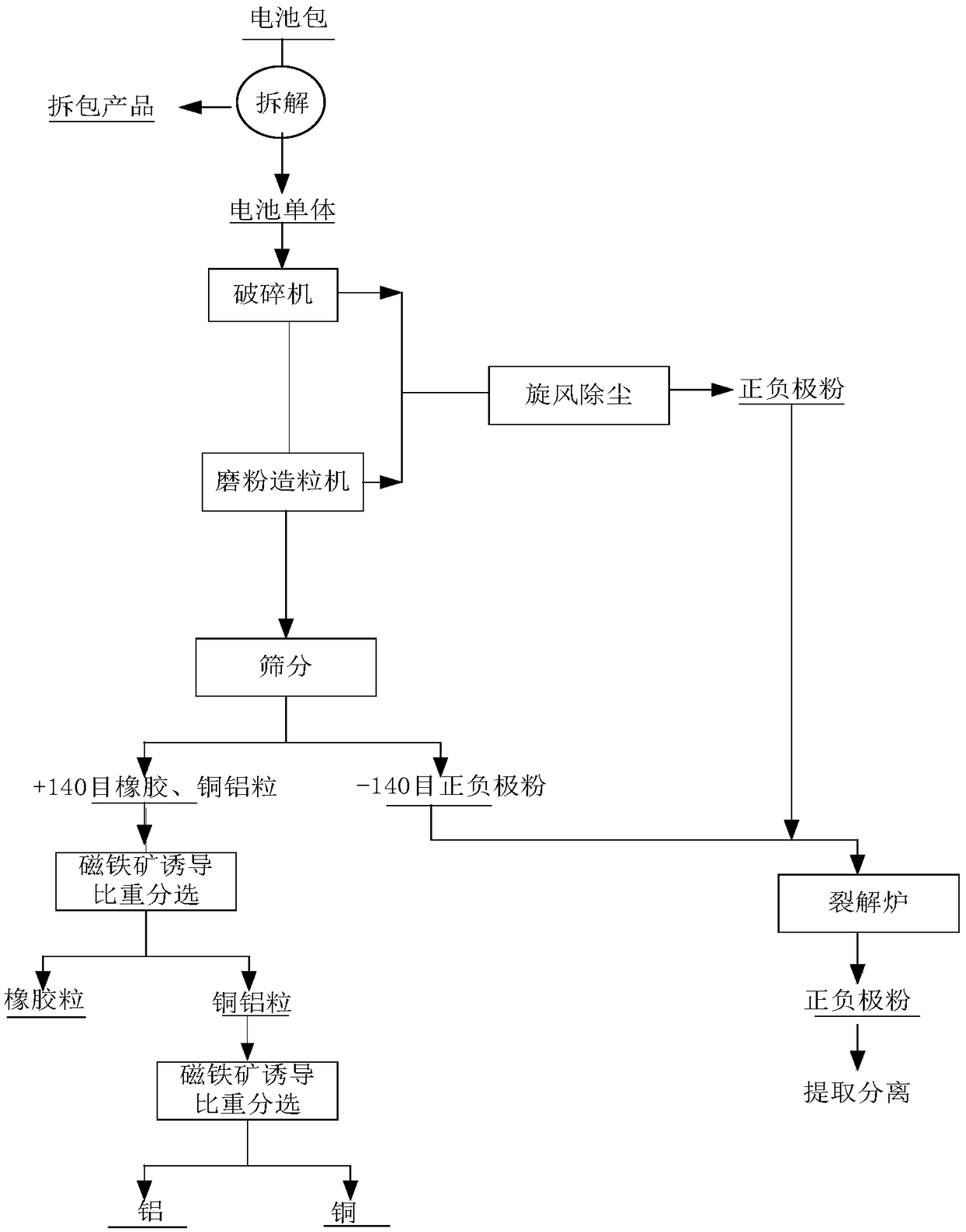

[0020] as attached figure 1 As shown, a method for recycling copper, aluminum and rubber in waste power lithium batteries comprises the following steps:

[0021] 1) Dismantling: 200kg of waste power battery packs are discharged and disassembled to obtain 150kg of battery cells;

[0022] 2) Crushing and granulation: 150kg of battery cells are crushed in one stage, and the dust removal equipment connected to the crushing equipment absorbs and collects plastic separators and fine-grained battery powders with light density, and then sieves them to obtain plastic separator products and battery powder products ;

[0023] 3) Screening: The first-stage crushed heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com