Beneficiation process for polymetallic ore containing gold, silver, lead and zinc

A multi-metal, gold and silver technology, applied in the direction of solid separation, etc., can solve the problems of reducing the valuation coefficient of gold and silver, high lead-zinc mutual content, loss, etc., and achieve the effect of increasing economic benefits of enterprises, efficient comprehensive recovery, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

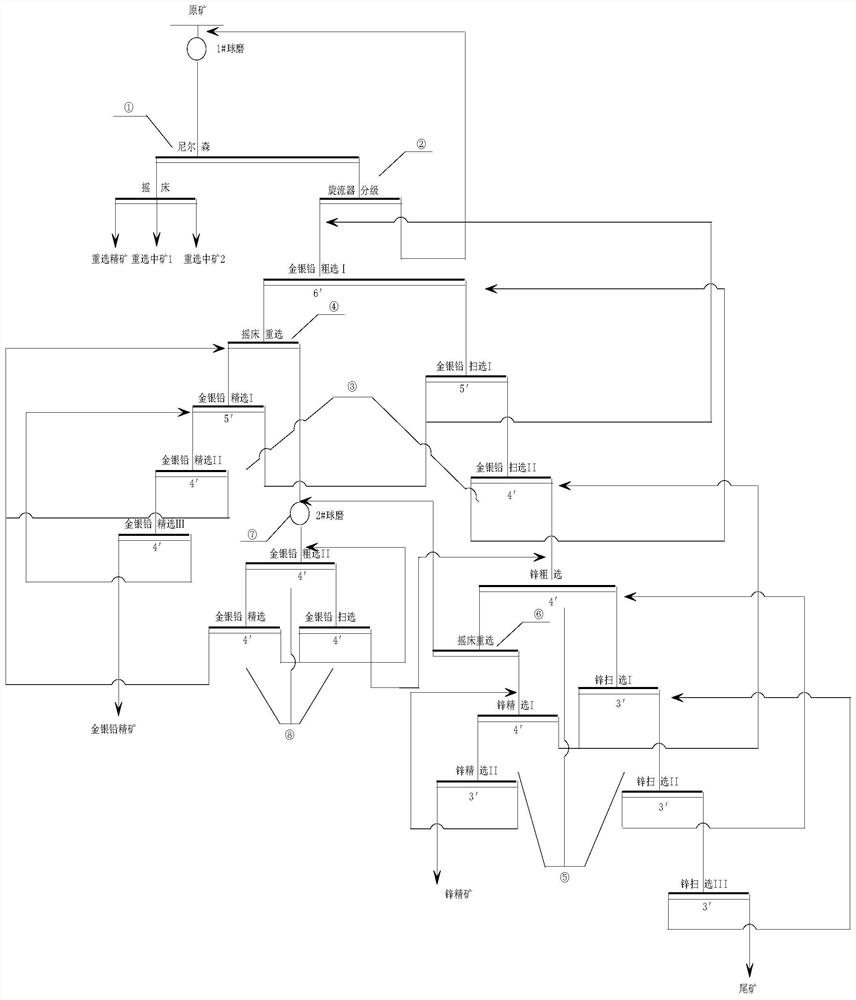

[0023] A multi-metal ore distribution process containing gold and silver lead-zinc, including the following steps:

[0024] Step 1, after the original ore is 1 # ball mill grinder (depending on the degree of mineral dissociation depending on the mineral dissociation of different ore), the reselection machine is reselected, and the re-selection concentrate produced into the shaker is re-selected. Reselecting concentrate, reselecting medium ore 1 and reselecting medium mine 2;

[0025] Step II. After steps, the reselection tailings produced after the choice of the mine machine reselection is graded by a cyclone, and the cyclone overflow product and a cyclone sandstone product are obtained. Ball mill internal milling;

[0026] Step three, the cyclone overflow products obtained by step I will perform the gold and silver lead flotation work to obtain the tailings of gold and silver lead coarse intensity and gold and silver lead float;

[0027] Step four, the gold and silver lead coarse...

Embodiment 2

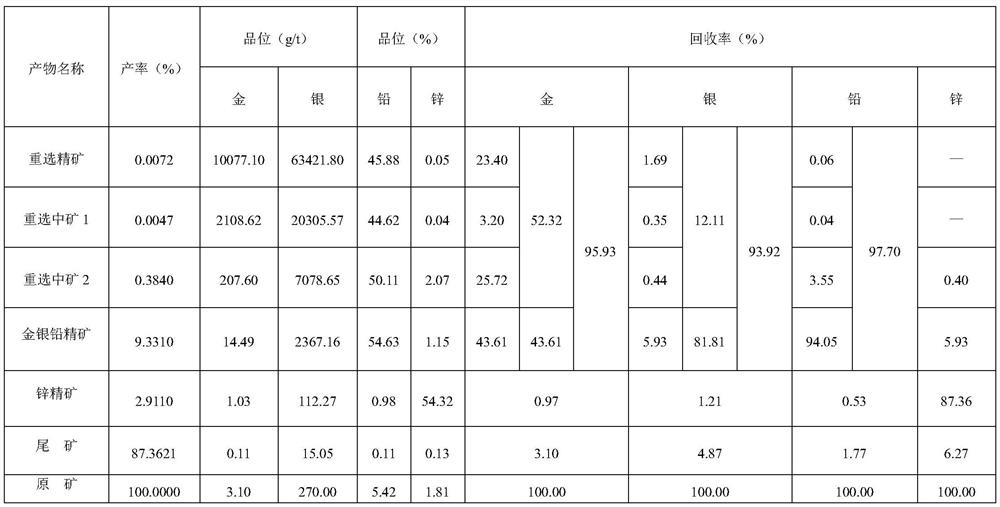

[0032] After 1 # ball mill grinding, the original mine entered the Nielsen + shaker reselection operation recovery monomer gold, silver (such as the ore without monomeric gold, silver, production can be omitted this operation), Nielsen retryed the tail mine fluid flow Rating, cyclone overflow products enter gold and silver lead flotation work, swirl sanding products return to milling; gold and silver lead flotation work coarse ore enters the shaker reselection operation, shake the bed reselection concentrate Three flotation selection operations received gold and silver lead concentrates, and the gold and silver lead flotation has entered the zinc-selected zinc operation after two sweeping operations. Re-selection operation, the shaker is retransmitted for three sellers to obtain zinc concentrates. It is selected from the selection of zinc. After three sweeping, the ricks are reselected and the coarse colry column shaker of the tailings and zinc coarse column shaker. After re-elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com