Beneficiation method for veinlet disseminated ore body type copper-lead-zinc-sulfur complex polymetallic ore

A polymetallic ore dressing method technology, applied in the field of metallurgy, can solve problems such as zinc minerals entering copper-lead concentrates, copper sulfide residues, and the separation of copper-lead mixed concentrates is difficult to achieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

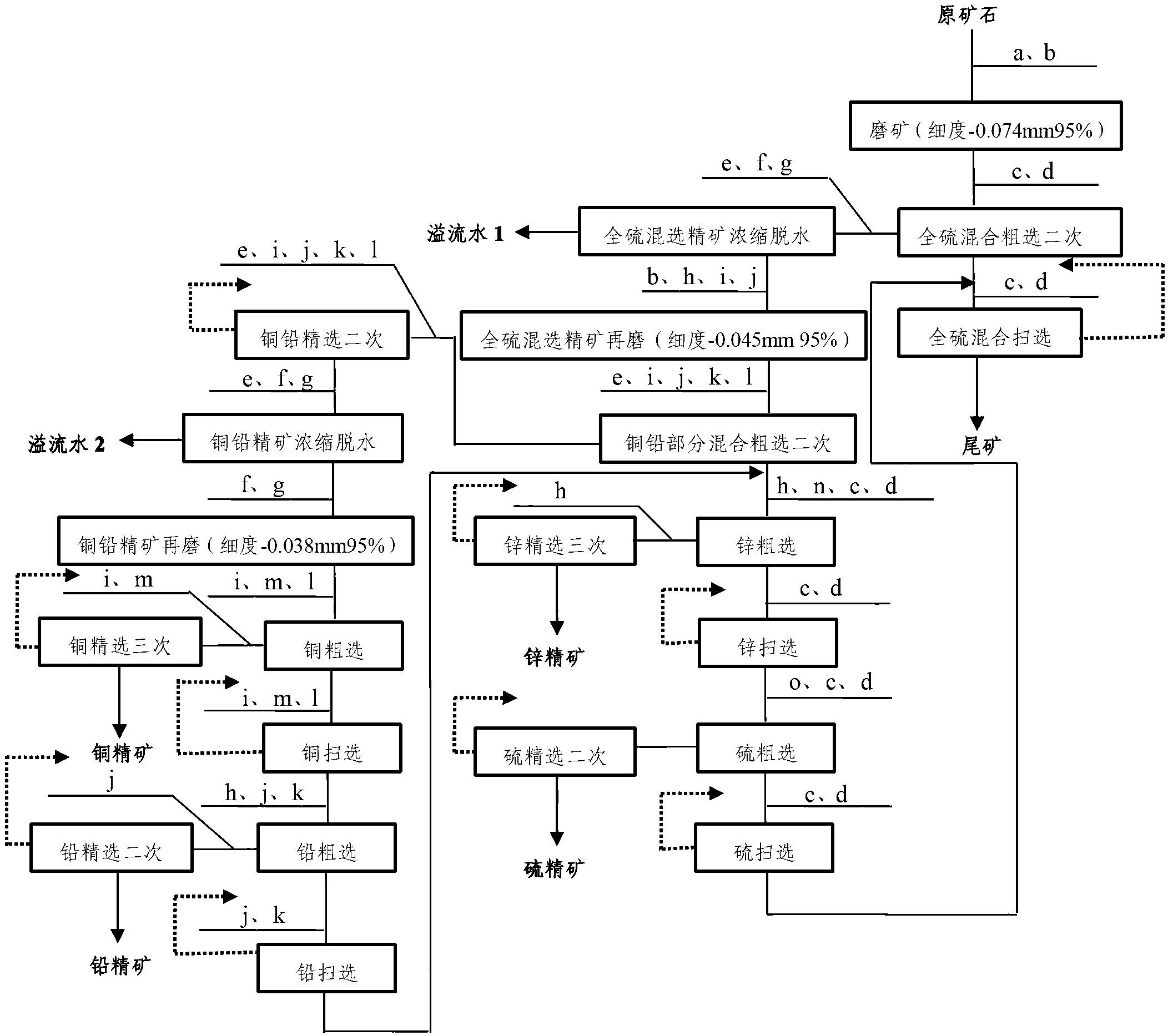

[0034] Example 1: The crushed raw ore and water are added to a ball mill in a ratio of 1:1 for grinding, and the amount of sodium sulfide 225g / t and sodium carbonate 525g / t are added to the grinding machine (based on the weight of raw ore dry ore The same below), until the grinding fineness of the ore grinding product is -0.074mm, accounting for 95%; the control pulp рН value is 7.5-8.0, and the total sulfur mixed roughing is carried out twice in the flotation machine, and the first total sulfur Add 72g / t of collector butylxanthate and 37g / t of 2# oil to the mixed roughing, add 37g / t of butylxanthate and 22g / t of 2# oil to the second total sulfur mixed roughing t, two full-sulfur mixed roughing concentrates are combined to enter the concentration dehydration operation, and the full-sulfur mixed roughing tailings are subjected to full-sulfur mixed sweeping; the amount of collector butyl xanthate added is 22g / t and the amount of 2# oil is 12g / t carry out mixed sulfur sweeping, ...

Embodiment 2

[0035] Embodiment 2: according to figure 1 The embodiment of the technological process of the present invention, the test steps, process parameters, and medicament system are exactly the same as those in Example 1. The specific technical indexes of embodiment 1 and embodiment 2 of the present invention are shown in table 1.

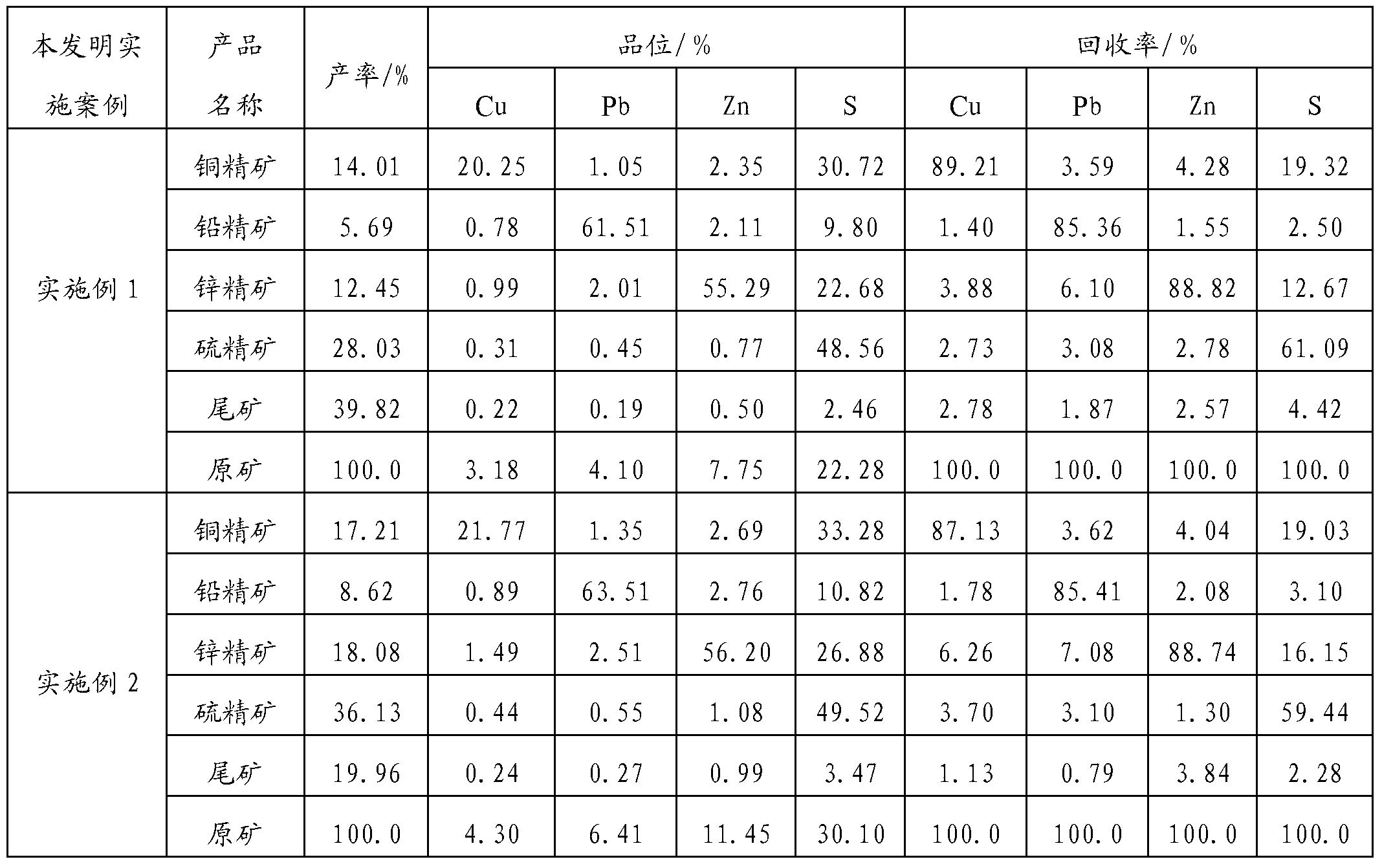

[0036] Table 1 embodiment of the present invention technological index

[0037]

[0038] Shown by the implementation result of embodiment 1 shown in table 1, embodiment 2 embodiment, adopt the inventive method, embodiment 1 raw ore contains Cu3.18%, Pb4.10%, Zn7.70%, S22.28% , can obtain the copper concentrate of 20.25% of copper grade, 89.21% of copper recovery rate, the lead concentrate of 61.51% of lead grade, 85.36% of lead recovery rate, the zinc concentrate of 55.29% of zinc grade, 88.82% of zinc recovery rate; Embodiment 2 The raw ore contains Cu4.30%, Pb6.41%, Zn11.45%, S30.10%, and obtained copper concentrate with copper grade of 21.77%, cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com