Flotation method for separation of copper-lead mixed concentrate adopting sodium hydroxide

A technology of sodium hydroxide and mixed concentrate, applied in flotation, solid separation, etc., can solve the problems of high production cost, poor separation effect, environmental pollution, etc., and achieve the effect of high recovery rate, no pollution, and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

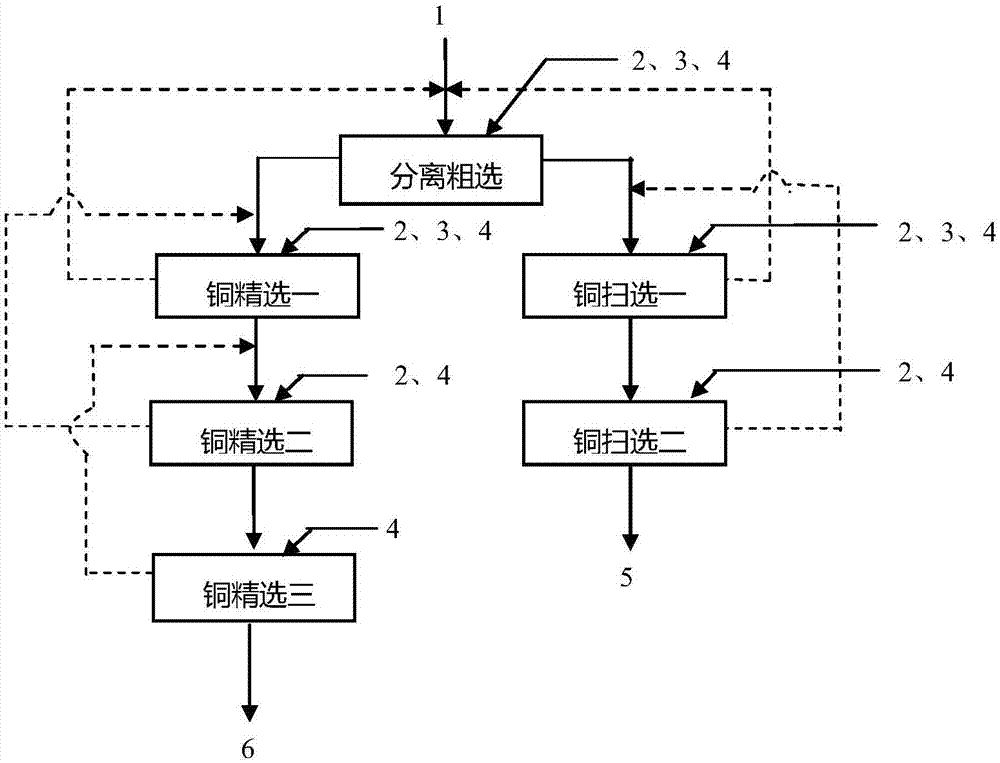

[0038] Embodiment 1: according to figure 1 In the process flow of the present invention shown, at first take 100 grams of copper-lead mixed concentrate dry mineral powder, then add water to adjust the slurry concentration to 18%, and then add it to a 500-milliliter flotation tank, and add it simultaneously in the flotation tank. 20 milliliters of sodium hydroxide solution of 10% concentration and 5 milliliters of zinc sulfate solution of 10% concentration, stirred for 3 minutes, then added 0.1 gram of ethylthiocarbamate, stirred for 1 minute and carried out copper-lead separation rough selection operation; Add 10 milliliters of sodium hydroxide solution of 10% concentration and 2.5 milliliters of zinc sulfate solution of 10% concentration simultaneously in the tailings of operation, stir for 3 minutes, then add 0.1 gram of ethylthiocarbamate, carry out copper scavenging after stirring for 1 minute Operation: Add 5 milliliters of sodium hydroxide solution of 10% concentration i...

Embodiment 2、 Embodiment 3

[0039] Embodiment 2, embodiment 3: according to figure 1 The technological process of the present invention shown, test procedure, medicament consumption and adding mode are identical with embodiment 1. The process indexes of embodiment 1, embodiment 2 and embodiment 3 of the present invention are shown in table 1.

[0040] Table 1 embodiment technological index

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com