Combined lead inhibitor for micro-fine particle galena and application of combined lead inhibitor

A combined inhibitor and inhibitor technology, applied in solid separation, flotation, etc., can solve the problems of incomplete suppression of fine-grained lead, low lead recovery rate, and large dosage of chemicals, so as to improve the separation efficiency of copper and lead and reduce the cost of chemicals. Low, reduce the effect of mutual inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

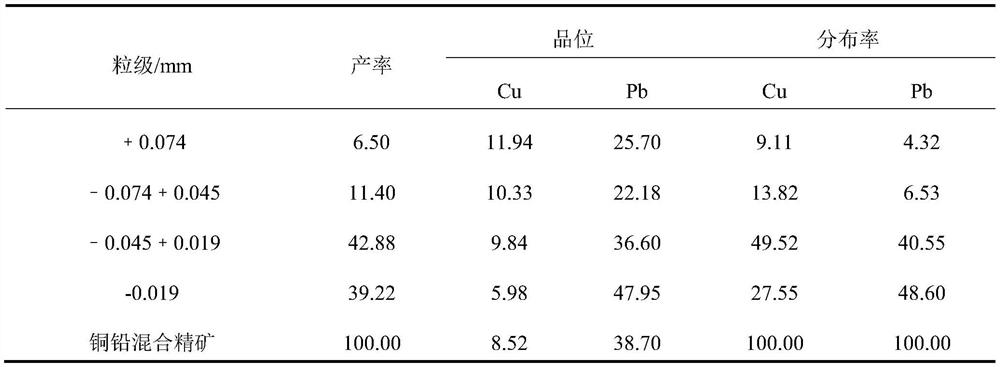

[0032] The copper-lead mixed concentrate sample was taken from the slurry at the overflow port of the regrinder before the separation of copper and lead in a concentrator in Dongshengmiao, Inner Mongolia. The copper-lead concentrate sample contains 8.56% copper and 38.67% lead. Among them, copper and lead mainly exist in the form of chalcopyrite and galena. Contains a small amount of pyrite, and small amounts of gangue minerals such as quartz, talc and mica. The particle size composition of copper-lead mixed concentrate is shown in Table 1. It can be seen from Table 1 that the regrind fineness is -0.045mm, accounting for 82.10%. Obviously, -19μm galena accounts for 48.60%. The effective suppression of is the difficulty in the separation of copper and lead in this ore. The particle size composition of copper-lead mixed concentrate is shown in Table 1.

[0033] Table 1 Copper-lead mixed concentrate particle size composition / %

[0034]

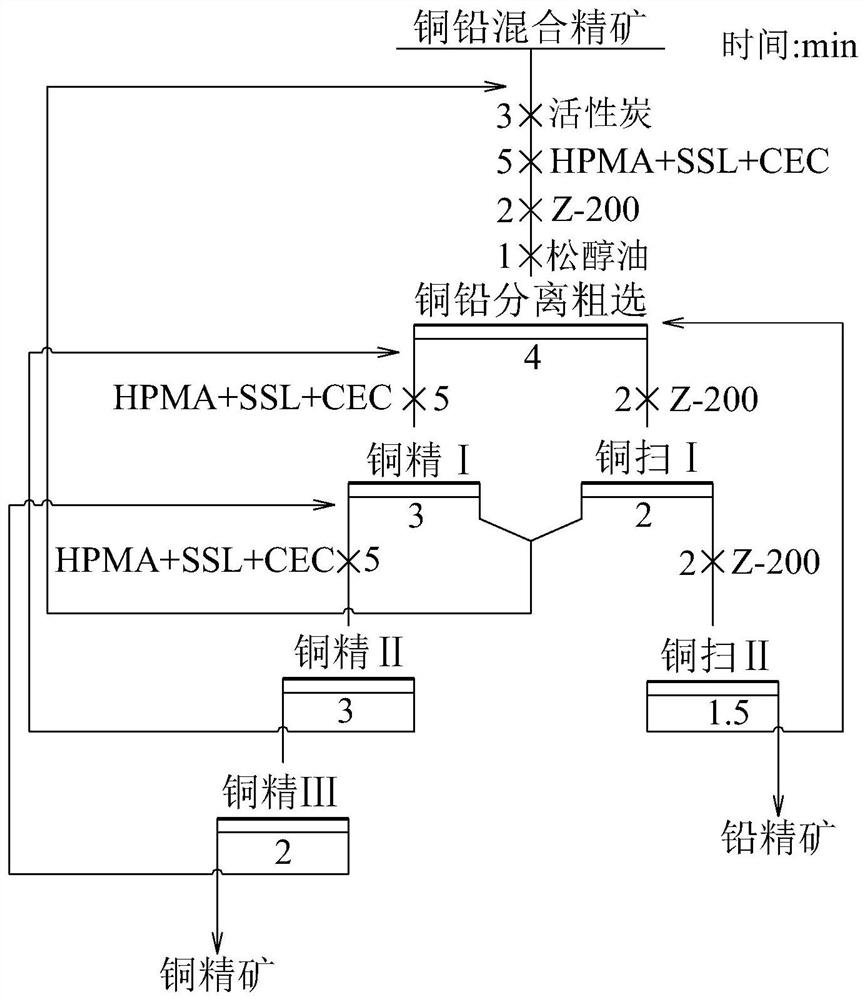

[0035] In this embodiment, the flot...

Embodiment 2

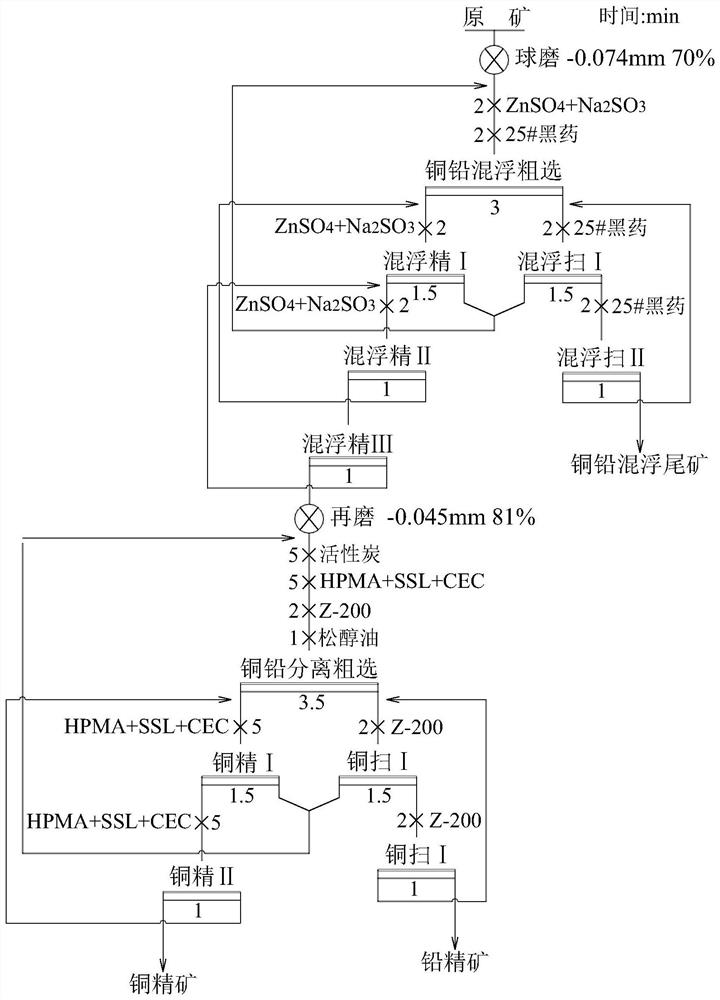

[0072] A complex copper-lead-zinc-silver-tin polymetallic mine in Xinjiang, the raw ore contains 0.21% copper, 1.41% Pb, 3.35% zinc, 4.71% sulfur, 127.3g / t silver, and 0.079% tin. The main metals in the ore are Minerals are pyrite, galena, sphalerite, arsenopyrite and a small amount of chalcopyrite, pyrrhotite, cassiterite, gangue minerals are mainly quartz, followed by muscovite, chlorite and dolomite. The mine is a silver-rich lead-zinc mine with high economic value. According to the results of the scheme exploration test, it is determined to adopt the scheme of "copper-lead mixed flotation-copper-lead mixed concentrate separation", and the selection process is as follows figure 2 shown. Raw ore grinding fineness -0.074mm accounts for 70%. Copper-lead mixed concentrate and copper-lead mixed floating tailings are obtained by adopting a process of first roughing, second sweeping and third refining. The quality and grade of the flotation concentrate and flotation tailings ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com