A targeted dosing method in the process of sulfide ore flotation polymetallic separation

A separation process, multi-metal technology, applied in flotation, solid separation, etc., can solve the problems of difficult control of multi-metal separation indicators, serious mutual inclusion of various separations, unsatisfactory suppression effect, etc., to achieve flexible return of water return and suppression The effect of reducing the dose and strengthening the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

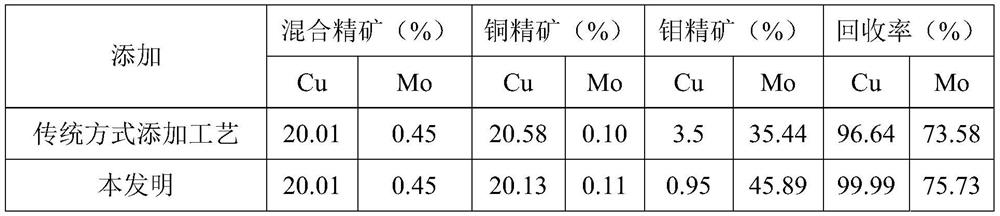

[0027] Experimental example: Separation of copper sulfide and molybdenum sulfide in a copper-molybdenum mine in Tibet

[0028] Since the flotation separation of polymetallic sulfides involves the separation of different metal sulfides, the inhibitors used are different according to the type of ore and the characteristics of the ore;

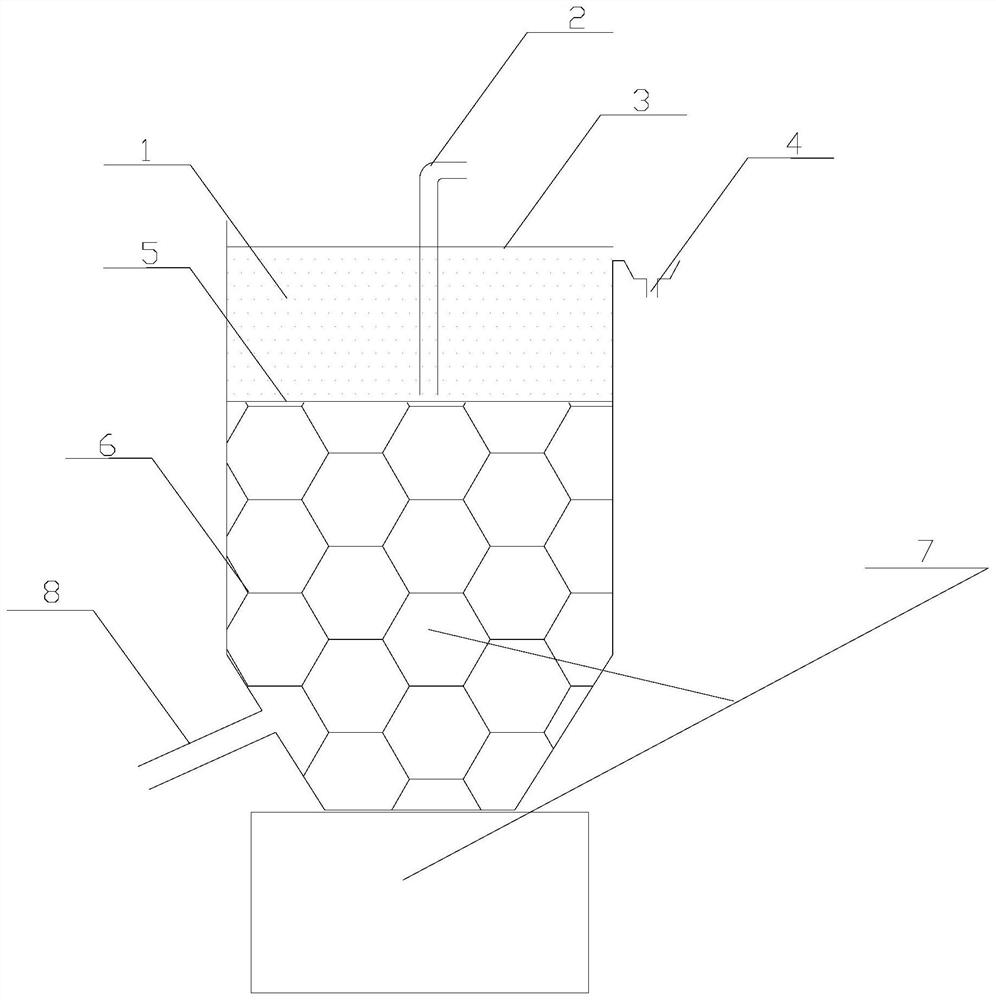

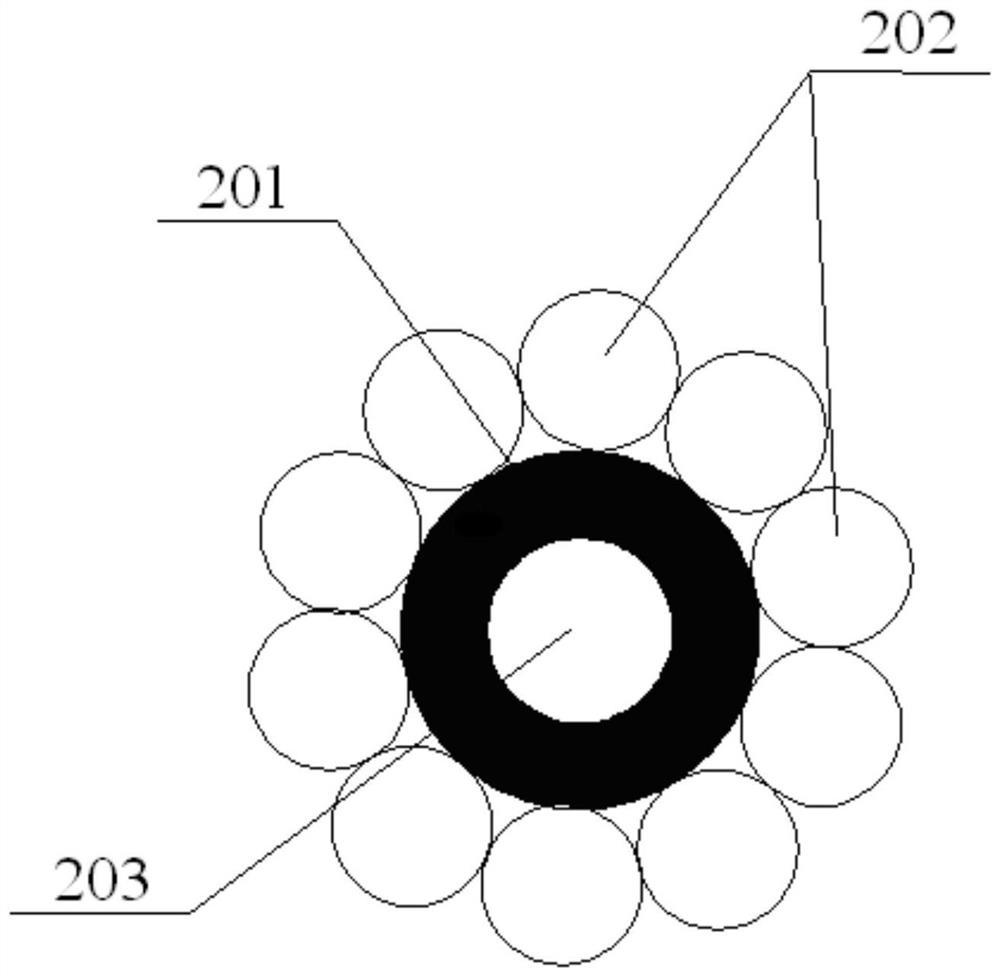

[0029] The mine beneficiation processes copper-molybdenum ore. The technological process is: mixed flotation-copper-molybdenum separation. Mine, the present invention is applied in the fifth selection process of depressant addition;

[0030] The foam of each flotation operation enters the next operation in sequence, and the tailings return in sequence;

[0031] The types of conventional dosing process inhibitors are: sodium hydrosulfide, dosage (total amount):

[0032] The dosing process inhibitor kind of the present invention is: sodium hydrosulfide, consumption (total amount):

[0033] Other selected operations are added according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com