An Annular and Radial Mixed Channel Magnetorheological Valve

A technology of radial mixing and magneto-rheological valves, applied in the field of magnetorheological valves, can solve problems such as pressure drop of magnetorheological valves, achieve the effects of reducing magnetic loss, improving performance, and increasing utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

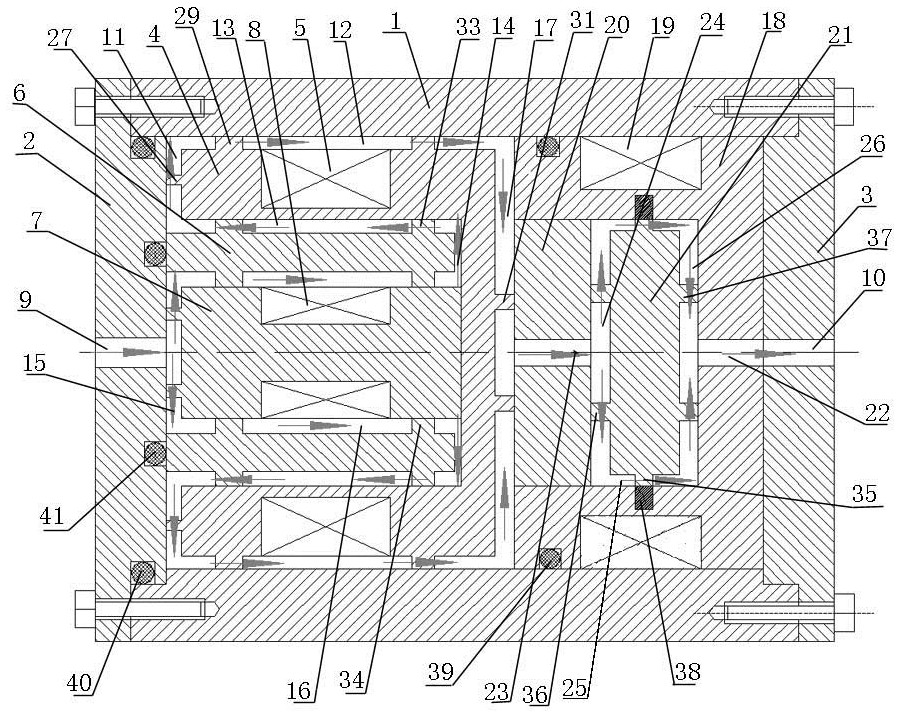

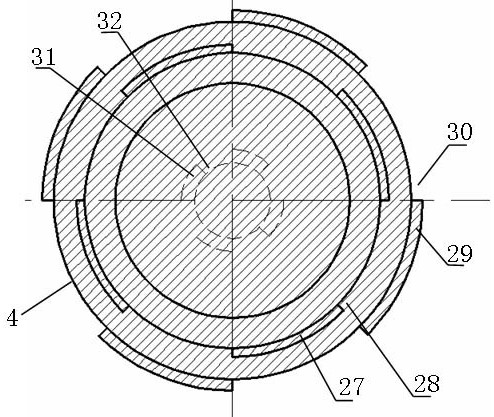

[0043] like Figure 1-2 As shown, the annular and radial mixed channel magnetorheological valve includes valve body 1, left end cover 2, right end cover 3, left coil support 4, left excitation coil 5, left magnetic conducting ring 6, left valve core 7. Left spool excitation coil 8;

[0044] Both ends of the valve body 1 are sealed by the left end cover 2 and the right end cover 3 respectively, the left end cover 2 is provided with a through hole a9 in the middle, and the right end cover 3 is provided with a through hole b10 in the middle;

[0045] The valve body 1 is divided into a left valve body and a right valve body;

[0046] The left coil support 4 is arranged in the inner wall of the valve body 1 and is located in the left valve body part; the left coil support 4 is a ring structure with a closed right end; the left end face of the left coil support 4 corresponds to On the right end face of the left end cover 2, there is a space between the left end face of the left co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com