Gland packing

A gland and fiber technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of brittleness and easy folding, low tensile strength, etc., and achieve the effect of reducing friction coefficient and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

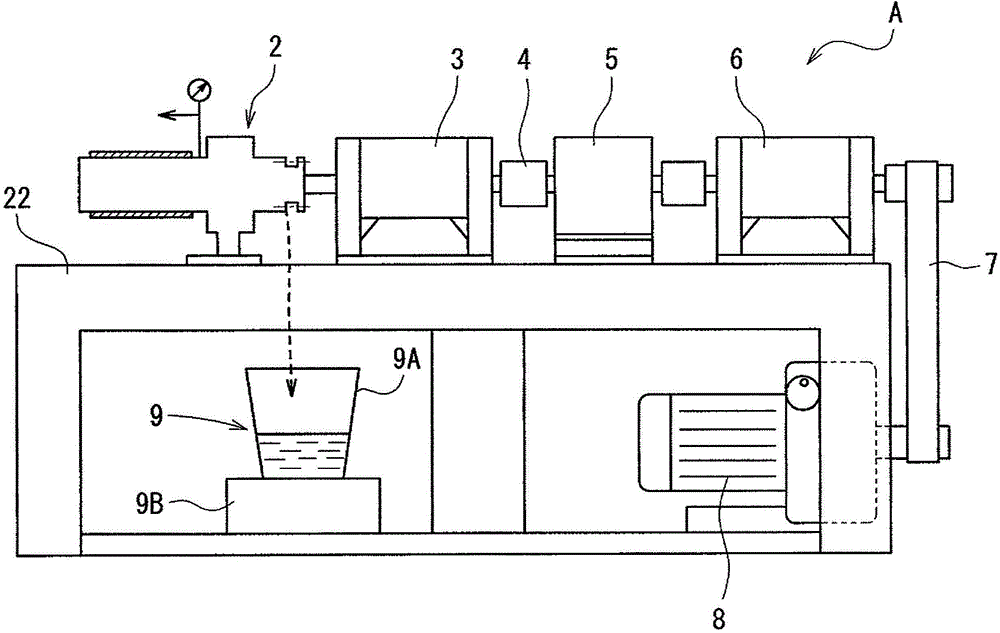

Method used

Image

Examples

Embodiment approach 1

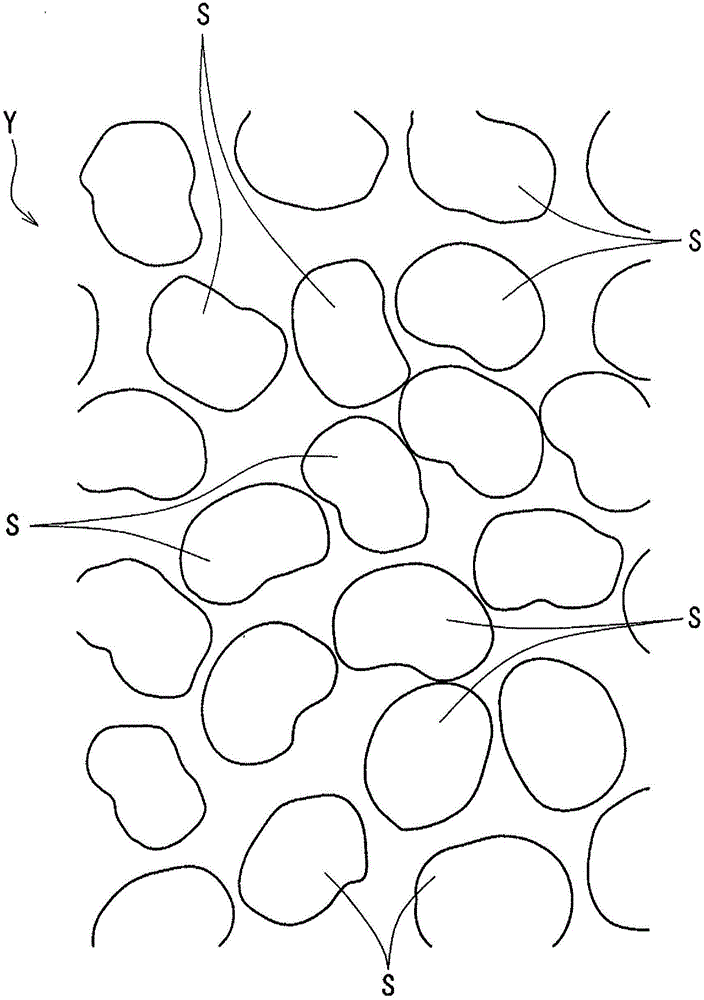

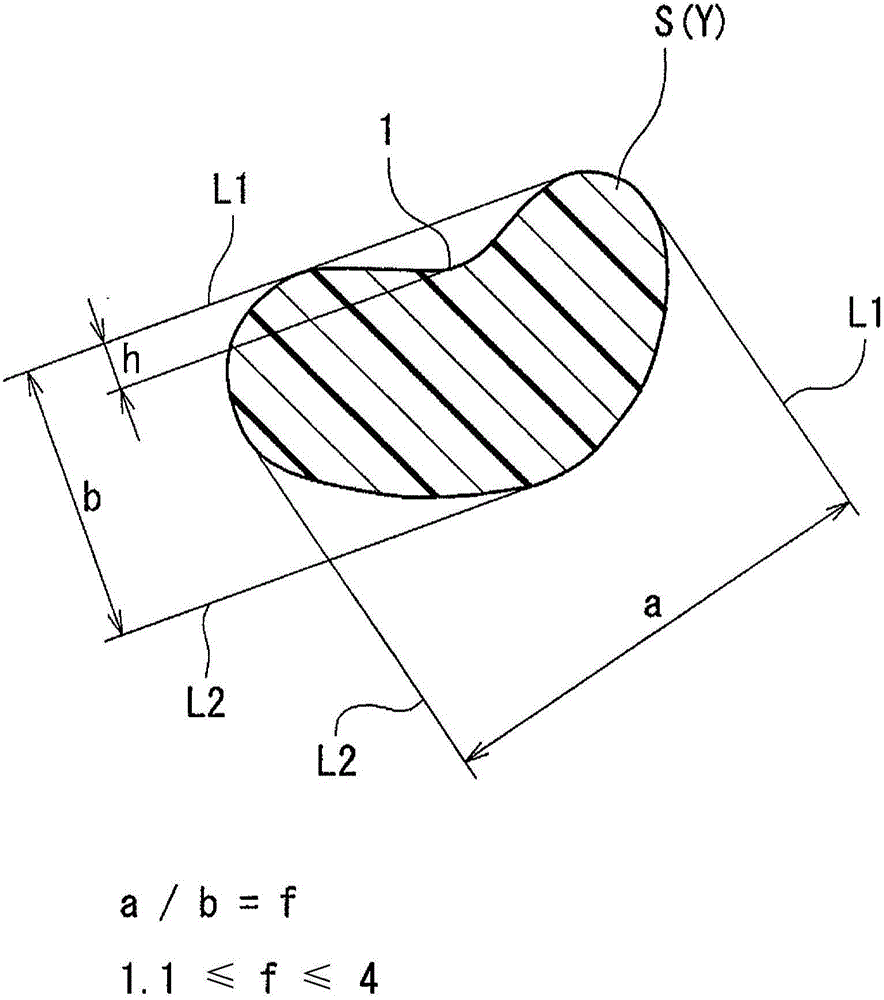

[0045] The gland packing of the present invention is characterized in that it is formed by twisting or weaving one or more yarns obtained by twisting fibers with an LOI of 21 to 30, and the fiber s contains flatness f defined as For fibers of 1.1 to 4, the flatness f is obtained by dividing the maximum value a of the interval between the two straight lines L1, L2 between the two parallel straight lines L1, L2 in the state where the cross section of the fiber is sandwiched. The value obtained with the minimum value of b.

[0046] In Embodiment 1, the value e of the LOI of the fiber is 21≤e≤30, and the flatness f is 1.1≤f≤4.

[0047] First, the fiber whose LOI value e is 21≦e≦30 may, for example, be acrylic fiber, acrylic fiber, viscose, cellulose, hemp, cotton or polyvinyl alcohol.

[0048] Acrylic fibers include fibers made of polymers containing 50% by weight or more of acrylonitrile. When the polymer contains 50% by weight or more of acrylonitrile, the polymer may be a cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com