Gland packing

A gland and fiber technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of low tensile strength and easy breakage, and achieve the effects of less leakage, good adaptability and less stress relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0042] The gland packing of the first embodiment is characterized in that it is obtained by twisting or braiding a single or a plurality of twisted (twisting) fibers having an LOI of 21 to 30. That is, the value e of the LOI of the fiber satisfies the condition of 21≦e≦30.

[0043] Examples of fibers whose LOI value e satisfies the condition of 21≦e≦30 include acrylic fibers, acrylic fibers, viscose, cellulose, hemp, cotton, and polyvinyl alcohol.

[0044] Acrylic fibers include those formed from polymers containing more than 50% by weight of acrylonitrile. The polymer may be a copolymer of acrylonitrile and an unsaturated monomer copolymerizable with acrylonitrile as long as it contains 50% by weight or more of acrylonitrile.

[0045] Examples of unsaturated monomers that can be copolymerized with acrylonitrile include: methyl acrylate, ethyl acrylate, isopropyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate, 2-hydroxyethyl acrylate, acrylic acid Acrylates such as hydrox...

Embodiment

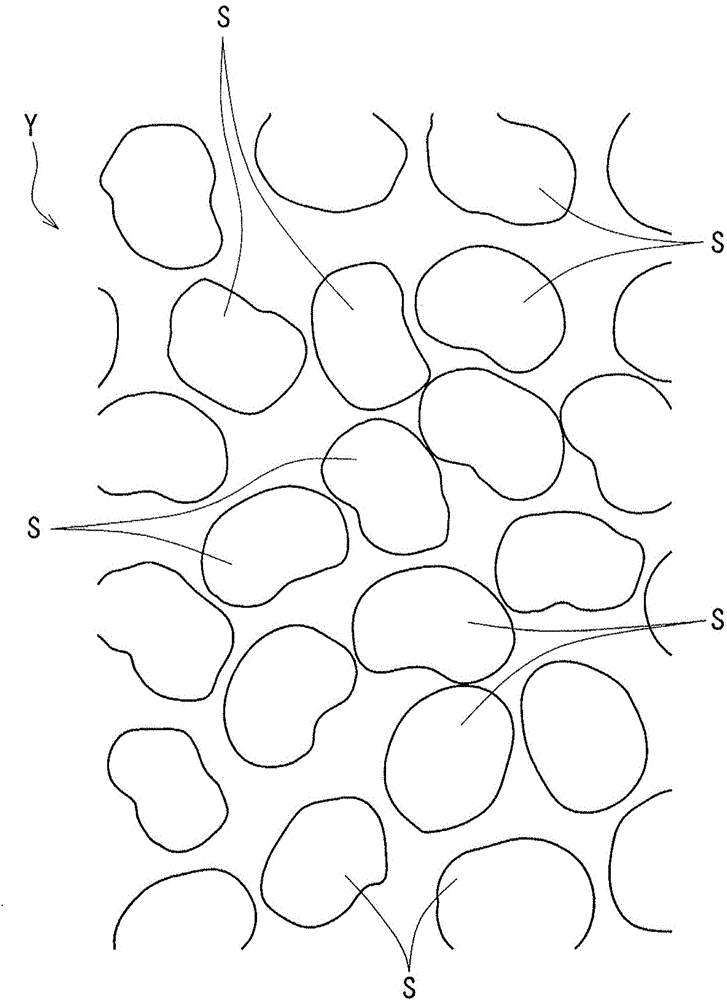

[0077] The fiber s used in the thread Y of the gland packing g is an acrylic fiber or an acrylic fiber, and the fiber diameter thereof is 18 (14 to 20) μm. The LOI of the fiber used was measured in accordance with JIS (Japanese Industrial Standards) K 7201-2 "Plastics - Test method for flammability based on oxygen index - Part 2: Test at room temperature".

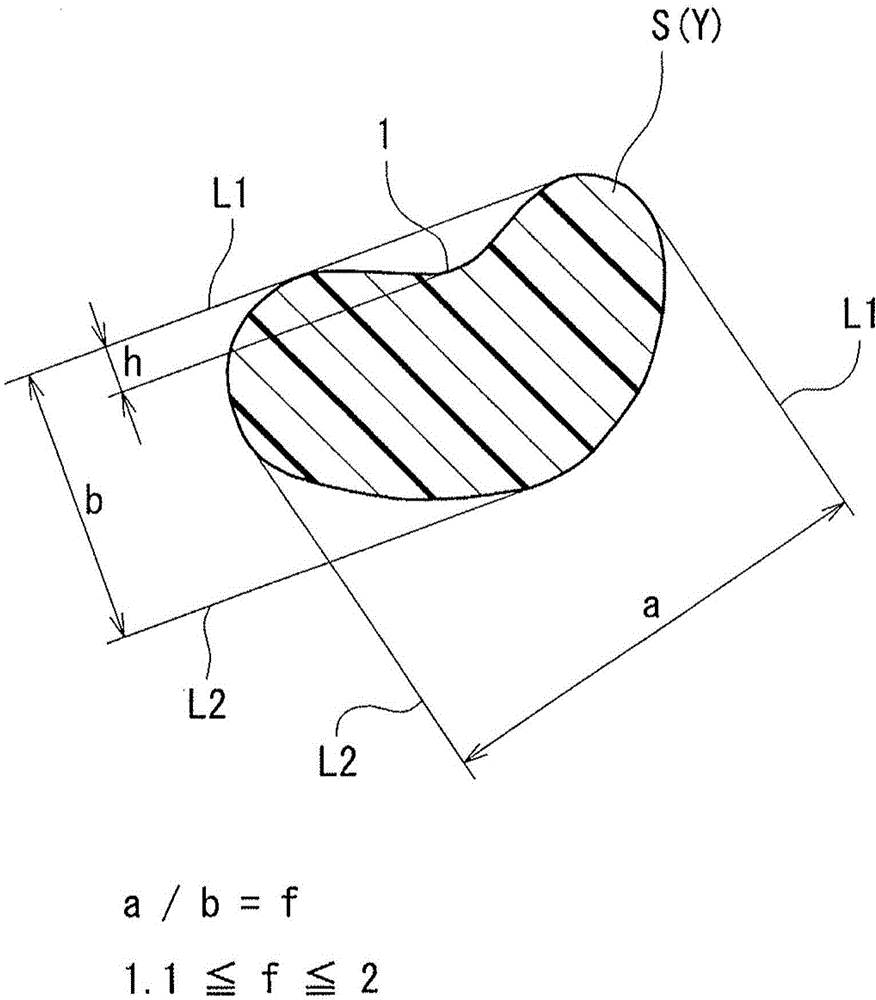

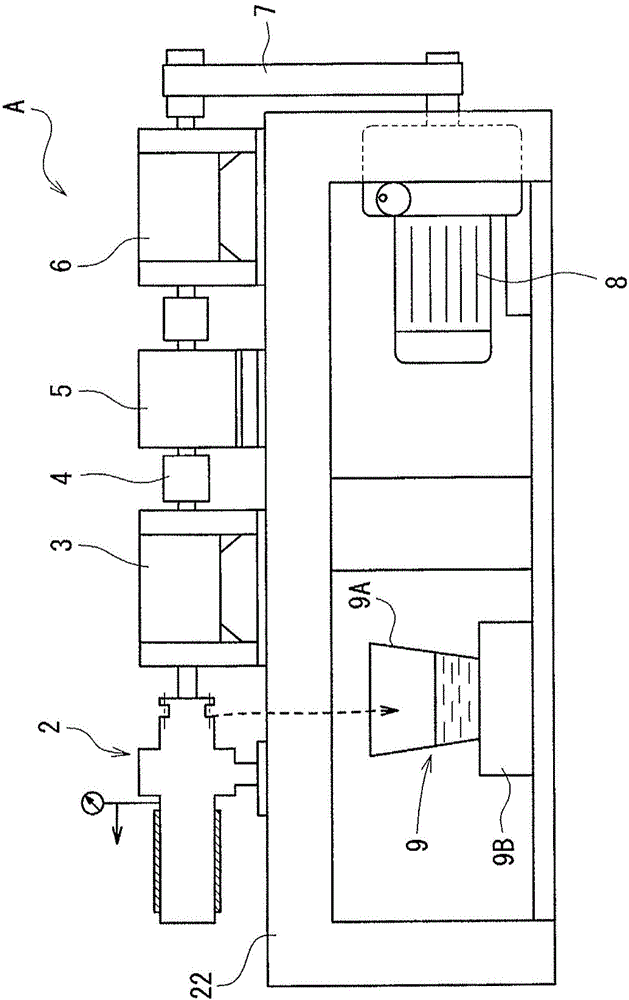

[0078] First, a plurality of the aforementioned fibers are twisted to produce a yarn Y. Next, using a knitting machine (not shown), weave through 8 strands of square knitting (8打ち角编み) using 8 threads (braiding yarns) Y, or 16 strands of circular knitting using 16 threads Y (16打ち丸编み) ) to make strip-shaped gland packing g, but the twisted tape can be used to make gland packing.

[0079] Then, using a 2-point roll (2-point roll) or a 4-point roll (4-point roll), the strip-shaped packing is made into a square strip-shaped gland packing g with a length of 14.5 mm on one side and a square section. The gland packing g is then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com