Honeycomb core end surface gridding sizing process method based on adhesive film thermal fracture

A process method and honeycomb core technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of poor adhesive distribution uniformity, blockage of honeycomb core air holes, volatile matter residues, etc., and achieve a physical distribution state Uniformity, meet the chemical state change, the effect of grid sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

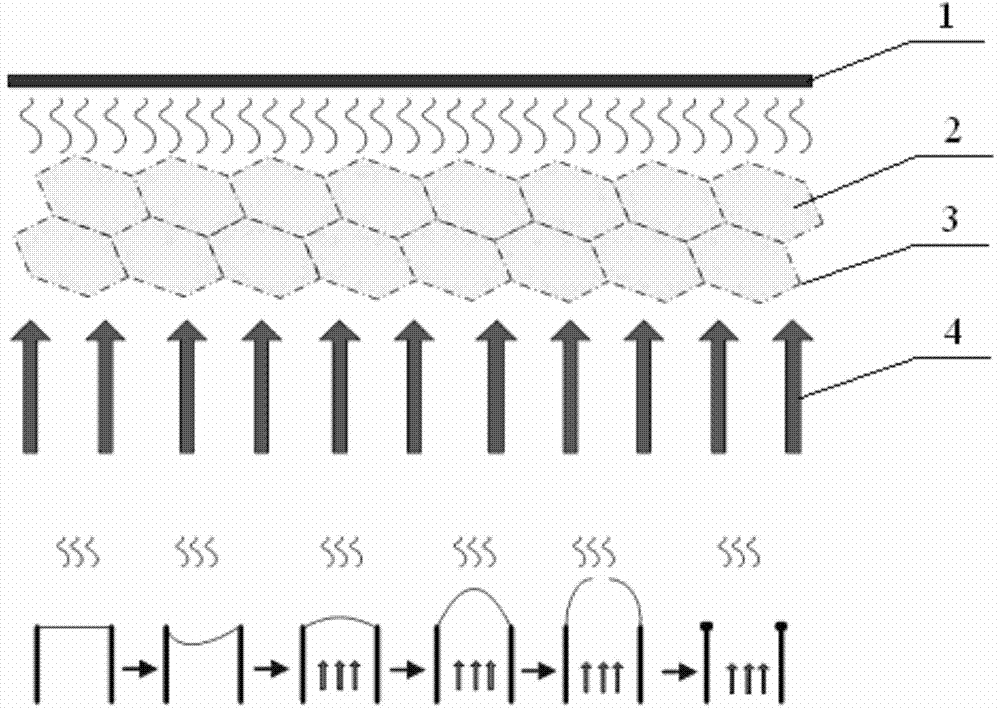

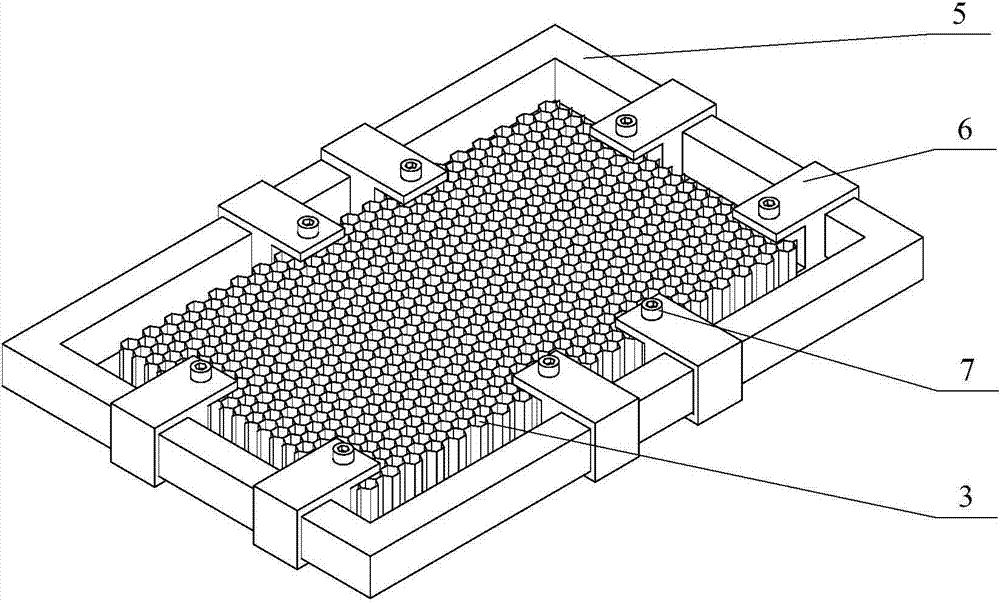

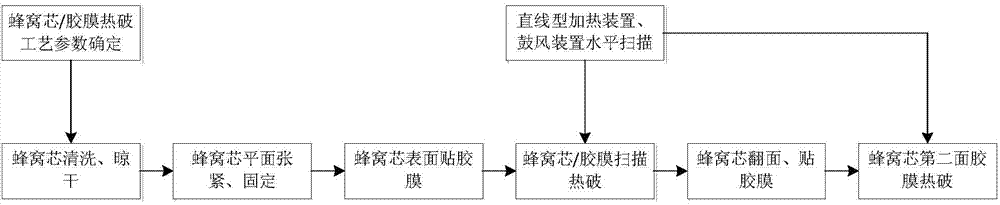

[0047] The honeycomb core 3 of the present embodiment, its material, specification are perforated aluminum honeycomb core material-27-5-0.03(LF2Y)-HB5443-T24, external dimension is 1300mmX1900mm, promptly honeycomb core 3 is aluminum honeycomb core, and the edge of core The length is 5 mm, the thickness of the core wall is 0.03 mm, and there are air holes, and the thickness of the honeycomb core is 24 mm; the structural adhesive film 2 of this embodiment is an epoxy structural adhesive film with a thickness of 0.1 mm. It is necessary to realize the grid distribution of the epoxy adhesive film 2 on the end face of the aluminum honeycomb core 3 through the thermal breaking process, so that the epoxy adhesive film 2 is evenly distributed along the hexagonal edges of the aluminum honeycomb core 3 .

[0048] The linear heating device 1 and the linear blowing hot air device 2 required by this embodiment can be operated horizontally and synchronously. The linear heating device 1 adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com