Preparation method and application of chiral MOF nanofiber-graphene hybrid material

A nanofiber and graphene technology is applied in the field of preparation of chiral MOF nanofiber-graphene hybrid materials to achieve the effects of easy operation, simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation method of a chiral MOF nanofiber-graphene hybrid material

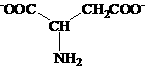

[0027] 0.08 g of graphene oxide, 0.3 g of copper nitrate and 70 mL of water were blended and ultrasonicated at room temperature for 5 min to fully dissolve them to obtain a graphene oxide@Cu(II) aqueous solution; 0.45 g of L-aspartic acid acid, 15 mL of water and 0.20 g of NaOH were blended and dissolved to obtain an aqueous solution of L-aspartic acid salt; under stirring, the aqueous solution of L-aspartic acid salt was added dropwise to the aqueous solution of graphene oxide@Cu(II), Stand at room temperature for 1 hour, filter with suction, wash the precipitate three times with water and ethanol, and dry at 60°C to obtain the MOF nanofiber-graphene hybrid material.

[0028] The chiral MOF nanofiber-graphene hybrid material is a graphene nanosheet-loaded chiral MOF nanofiber composite material; the chiral MOF nanofiber has a length of 500-800um and a diameter width of 70-90nm.

[0029] ...

Embodiment 2

[0031] Example 2 Preparation method of a chiral MOF nanofiber-graphene hybrid material

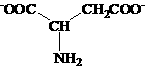

[0032] Blend 0.12 g of graphene oxide, 0.7 g of copper nitrate and 90 mL of water and sonicate at room temperature for 10 min to fully dissolve it to obtain a graphene oxide@Cu(II) aqueous solution; mix 0.65 g of L-aspartic acid, 25 mL of water and 0.26 g of NaOH were blended and dissolved to prepare the L-aspartic acid salt solution; under stirring, the L-aspartic acid salt solution was added dropwise to the graphene oxide@Cu(II) aqueous solution, and the Set aside for 1 h, filter with suction, wash the precipitate three times with water and ethanol respectively, and dry at 60°C to obtain a MOF nanofiber-graphene hybrid material.

Embodiment 3

[0033] Example 3 Preparation method of a chiral MOF nanofiber-graphene hybrid material

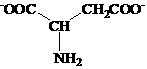

[0034] 0.10 g graphene oxide, 0.33 g copper nitrate and 80 mL water were blended and ultrasonicated at room temperature for 7 min to fully dissolve them to obtain a graphene oxide@Cu(II) aqueous solution; 0.55 g L-aspartic acid, 20 mL of water and 0.23 g of NaOH were blended and dissolved to prepare the L-aspartic acid salt solution; under stirring, the L-aspartic acid salt solution was added dropwise to the graphene oxide@Cu(II) aqueous solution, and the solution was static at room temperature. Set aside for 1 h, filter with suction, wash the precipitate three times with water and ethanol respectively, and dry at 60°C to obtain the MOF nanofiber-graphene hybrid material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com