Coordination polymer membrane material, preparation method for same and application of same in membrane separation

A coordination polymer and membrane material technology, applied in the separation of optically active compounds, separation/purification of carboxylic acid compounds, separation/purification of hydroxyl compounds, etc., can solve the problems of complex preparation process and less separation of organic liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

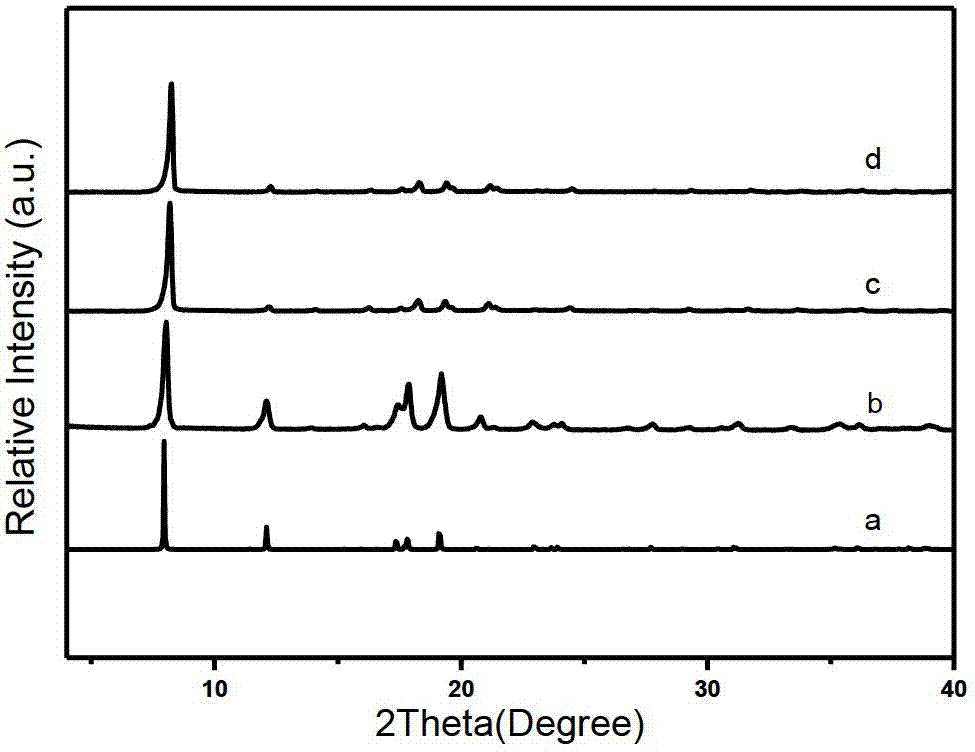

Examples

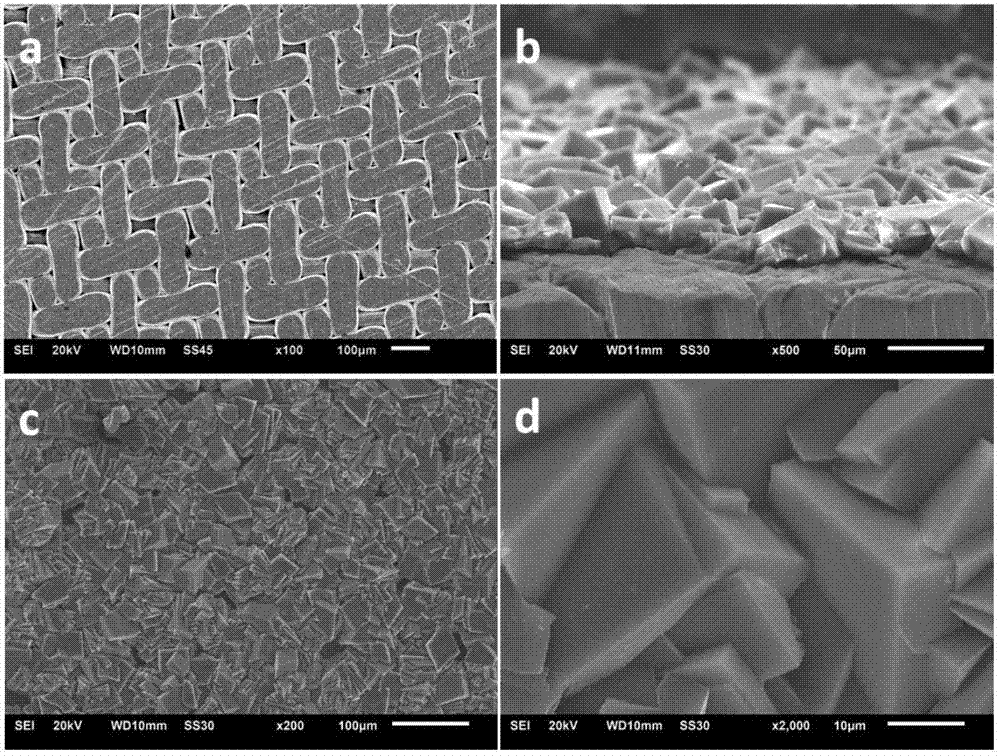

Embodiment 1

[0046] Step 1, pretreatment of the carrier:

[0047] Press 3 layers of 180-mesh nickel mesh (Henan Xinxiang 504 Factory) into a nickel mesh sheet at 20MPa on a hydraulic press, then put the pressed nickel mesh sheet into a 50ml beaker, add 20ml deionized water and 0.1g washing detergent (Liby detergent), ultrasonic for 30 minutes; then take out the nickel mesh and put it into a 50ml beaker, add 30ml of deionized water, ultrasonic treatment for 15 minutes and pour off the liquid in the beaker; repeat the deionized water ultrasonic cleaning step 5 times; finally take out the nickel mesh and put it into an oven at 100°C to dry for 5 hours, so as to obtain the cleaned nickel mesh carrier.

[0048] Step 2. In situ growth:

[0049] Add 0.1g of L-asp and 0.058g of bpy in a 20ml beaker, add 0.1ml of water and 1ml of methanol, stir well to get the reaction mother liquor, then transfer the reaction mother liquor to the reaction of stainless steel shell and polytetrafluoroethylene linin...

Embodiment 2

[0058] Step 1, pretreatment of the carrier:

[0059] Put a single-layer nickel mesh (180 mesh, Henan Xinxiang 504 Factory) into a 50ml beaker, add 20ml deionized water and detergent, and sonicate for 30 minutes. After taking it out, put it into a 50ml beaker, add 30ml of deionized water, perform ultrasonic treatment for 15 minutes, pour off the liquid in the beaker, and repeat the steps of ultrasonic cleaning with deionized water 5 times. After taking it out, put it into an oven at 100° C. to dry for 5 hours to obtain a cleaned single-layer nickel mesh carrier.

[0060] Step 2. In situ seed growth:

[0061] Add 0.1g of L-asp and 0.058g of bpy into a 20ml beaker, add 0.1ml of water and 1ml of methanol, stir well, transfer to a stainless steel shell, polytetrafluoroethylene-lined reactor, and complete the previous step Put the single-layer nickel mesh carrier horizontally into the reaction mother liquor, tighten the lid of the kettle, put it in a 150°C oven for in-situ growth ...

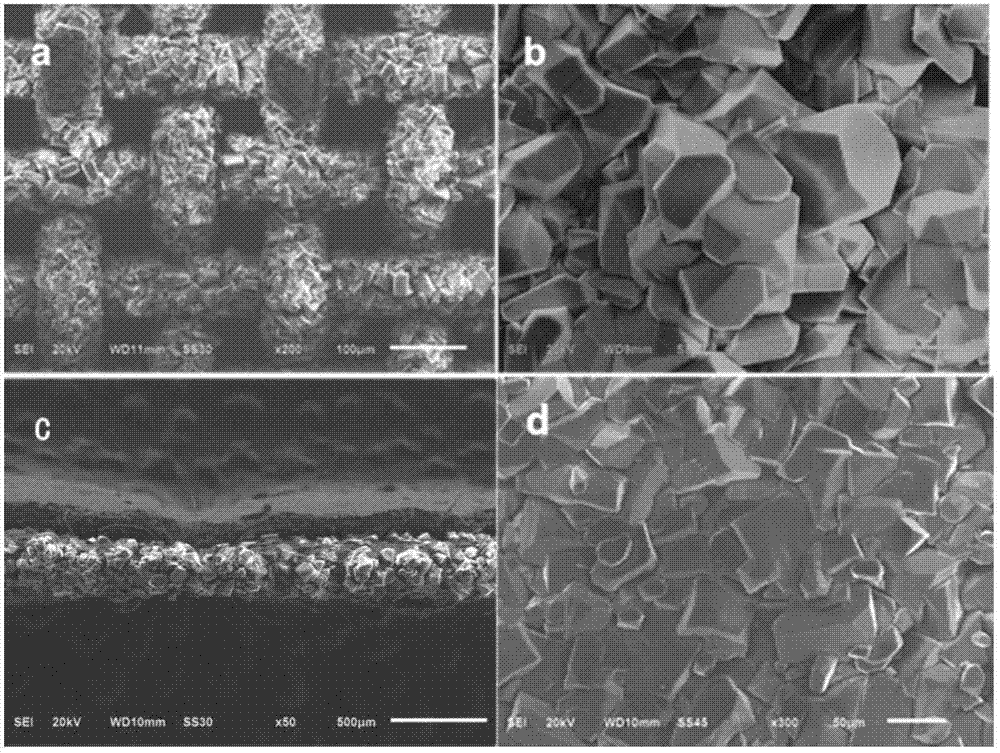

Embodiment 3

[0074] Step 1, step 2 and step 3 are the same as embodiment 2.

[0075] Step 4, secondary growth:

[0076] In a 20ml beaker, add Ni(L-asp)(H with a mass ratio of 0.219g 2 O) 2 , 0.156g of bpy, 6ml of water and 6ml of methanol, after stirring evenly, transfer to a reaction kettle lined with polytetrafluoroethylene with a stainless steel shell, and the previously synthesized surface has coordination polymerization Ni 2 (L-asp) 2 The nickel mesh carrier of the bpy seed crystal was placed vertically into the reaction mother liquor, and after tightening the lid of the kettle, it was placed in an oven at 150°C for in-situ growth for 2 days, and after taking it out, it was cooled to room temperature, and the secondary grown coordination polymer Ni was taken out 2 (L-asp) 2 bpy film.

[0077] Step 5, activation of membrane material:

[0078] Put the synthesized membrane material in an oven at 150°C for 10 hours, then take it out and cool it down to room temperature naturally to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com