Electronic horn using piezoelectric ceramic buzzer as diaphragm and sounding method thereof

A technology of piezoelectric ceramics and electronic horns, which is applied in the direction of sound-generating devices and instruments, can solve the problems of low sound-generating efficiency and high energy consumption, and achieve the effects of reduced power, light material, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

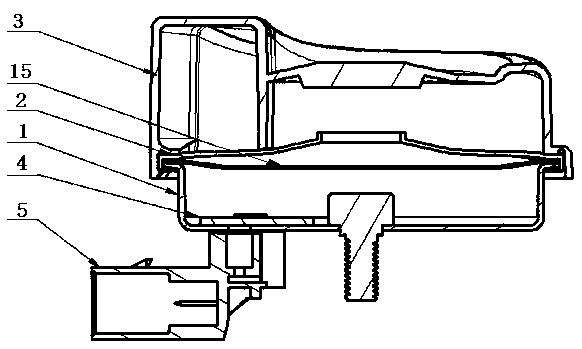

[0015] An electronic horn using a piezoelectric ceramic buzzer as a diaphragm, which consists of: a housing 1, a piezoelectric ceramic diaphragm 15 is installed between the housing and a gland 2, the housing, The glands are respectively connected to the loudspeaker housing 3, and a PCB circuit board 4 is installed in the housing, and the PCB circuit board and the piezoelectric ceramic diaphragm are connected by wires, and the PCB circuit board It has a connection terminal 5, and the housing is connected with a knurled connection device 6, and the knurled connection device is connected with a fixed frame, and the fixed frame is fixed on the locomotive.

Embodiment 2

[0017] According to the electronic horn using the piezoelectric ceramic buzzer as the diaphragm described in Embodiment 1, the acoustic channel 7 is provided in the sound amplifying shell.

Embodiment 3

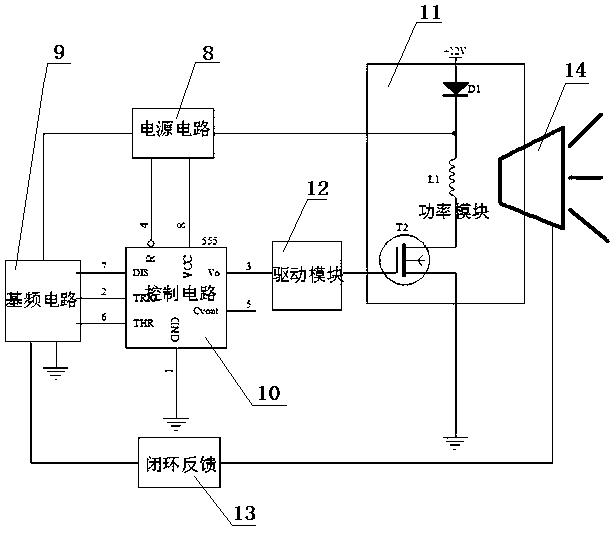

[0019] According to the electronic horn using the piezoelectric ceramic buzzer as the diaphragm described in Embodiment 1, the PCB circuit board includes a power circuit 8, and the power circuit is connected to the base frequency circuit 9, the control circuit 10, and the power module respectively. 11, the drive module 12 is installed between the control circuit and the power module, the base frequency circuit is connected to the closed-loop feedback circuit 13, and the closed-loop feedback circuit is connected to the speaker 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com