Tubular container with an outer tube and an inner container

A technology of inner container and outer tube, which is applied in the direction of soft tubular containers, containers, flexible containers, etc., can solve the problems of hindering the introduction of welding nozzles, insufficient pressure, and complicated polymer acquisition, so as to simplify the selection and reduce the thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

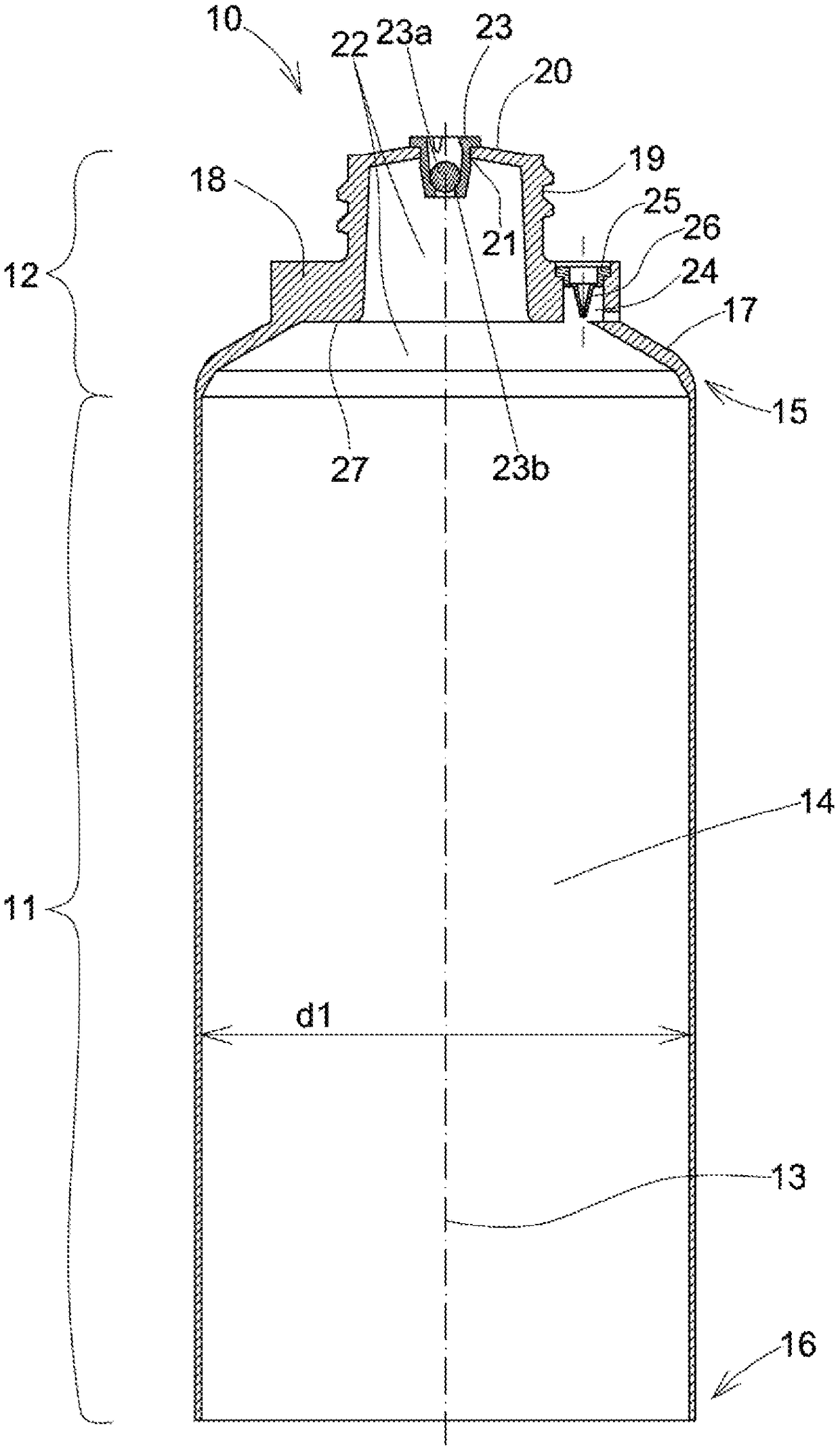

[0031] The present invention relates to a tubular container made of flexible material for containing cosmetics, food, medicine, etc. and a method of manufacturing the flexible tubular container. Tubular containers of this type are generally characterized as comprising a body or hollow skirt for containing a product (eg, a cosmetic cream), and a head disposed at one end of the skirt to allow the discharge or dosing of the product. The head can be equipped with a product outlet neck, cap, dosing mechanism, etc. Manufacturers of such tubular containers typically supply product marketers (such as cosmetic product marketers) with the head of the container closed, capped, sealed and generally finished, and the skirt at the other end open . The product marketer fills the tubular container with its product through the open end of the skirt, then seals said end of the skirt, and the tubular container and the product contained therein are ready for sale to the public.

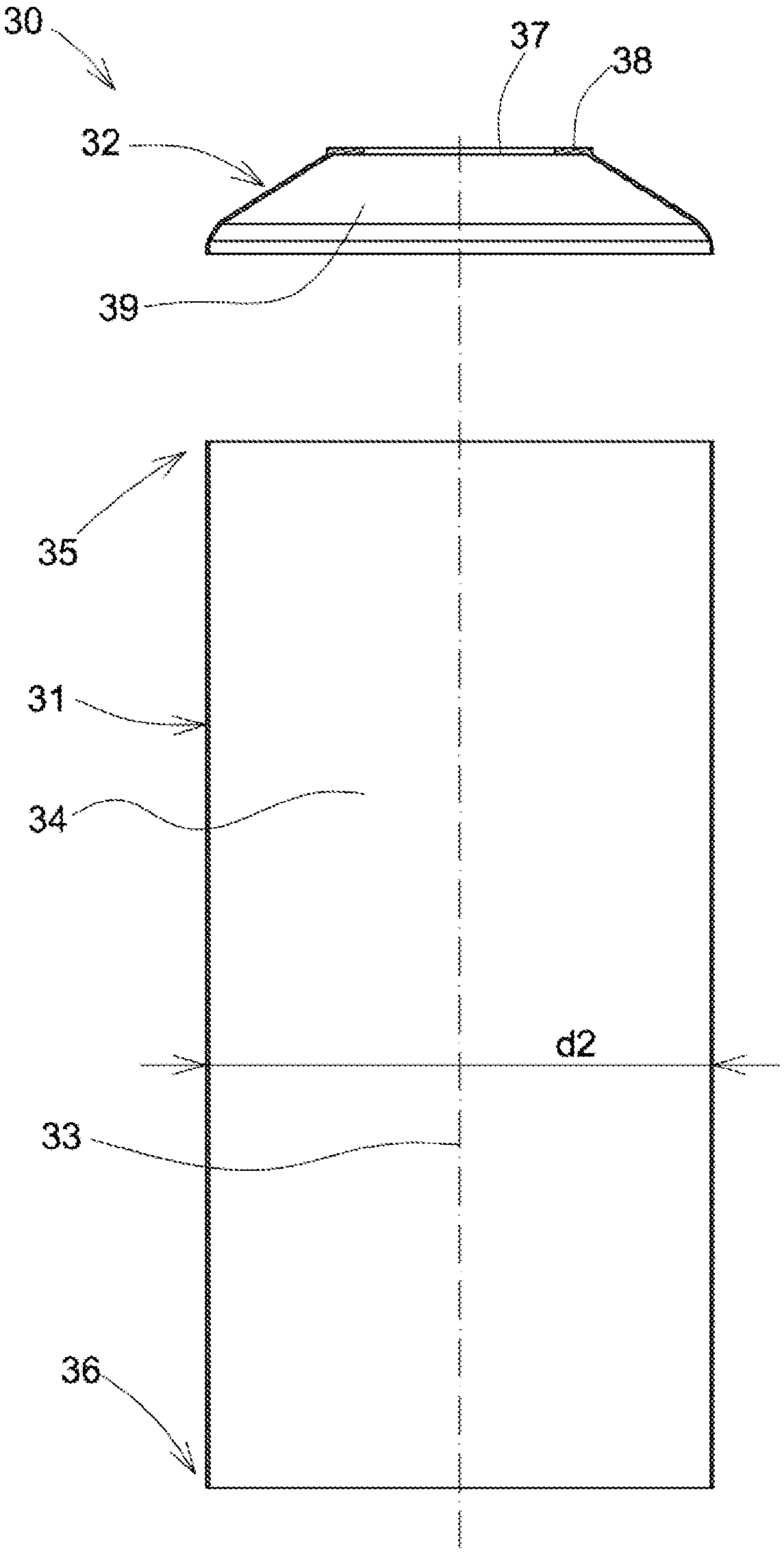

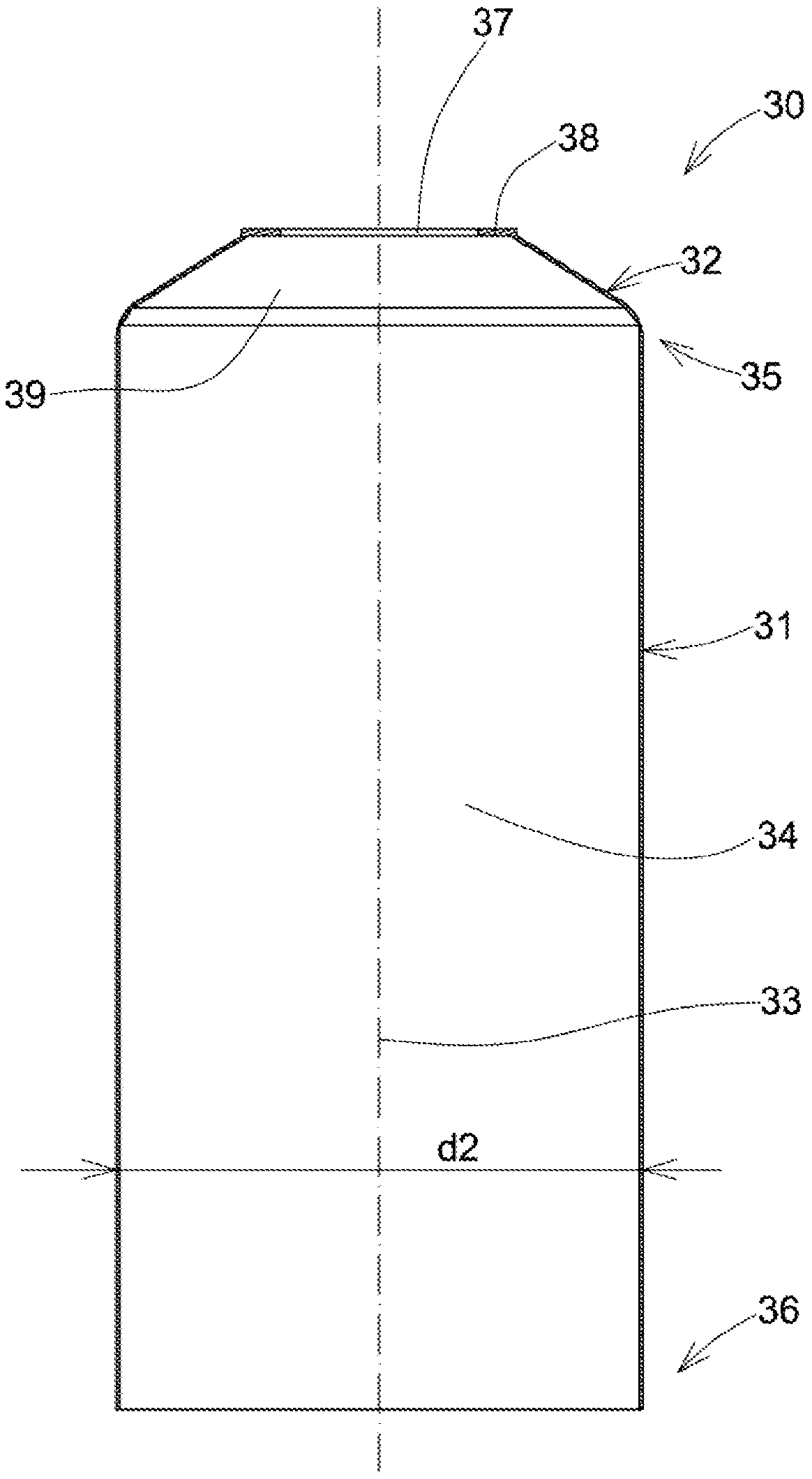

[0032] Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com