Peanut extracting oil and saving kernel apparatus and method and production of albumen powder, peanut powder

A peanut oil and protein powder technology, applied in food preparation, manufacturing tools, presses, etc., can solve the problems of shape and nutrient composition damage, peanut economic value and processing benefit reduction, waste of nutrient resources such as peanut protein, etc., to achieve oil production The effect of high yield, apricot yellow color and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

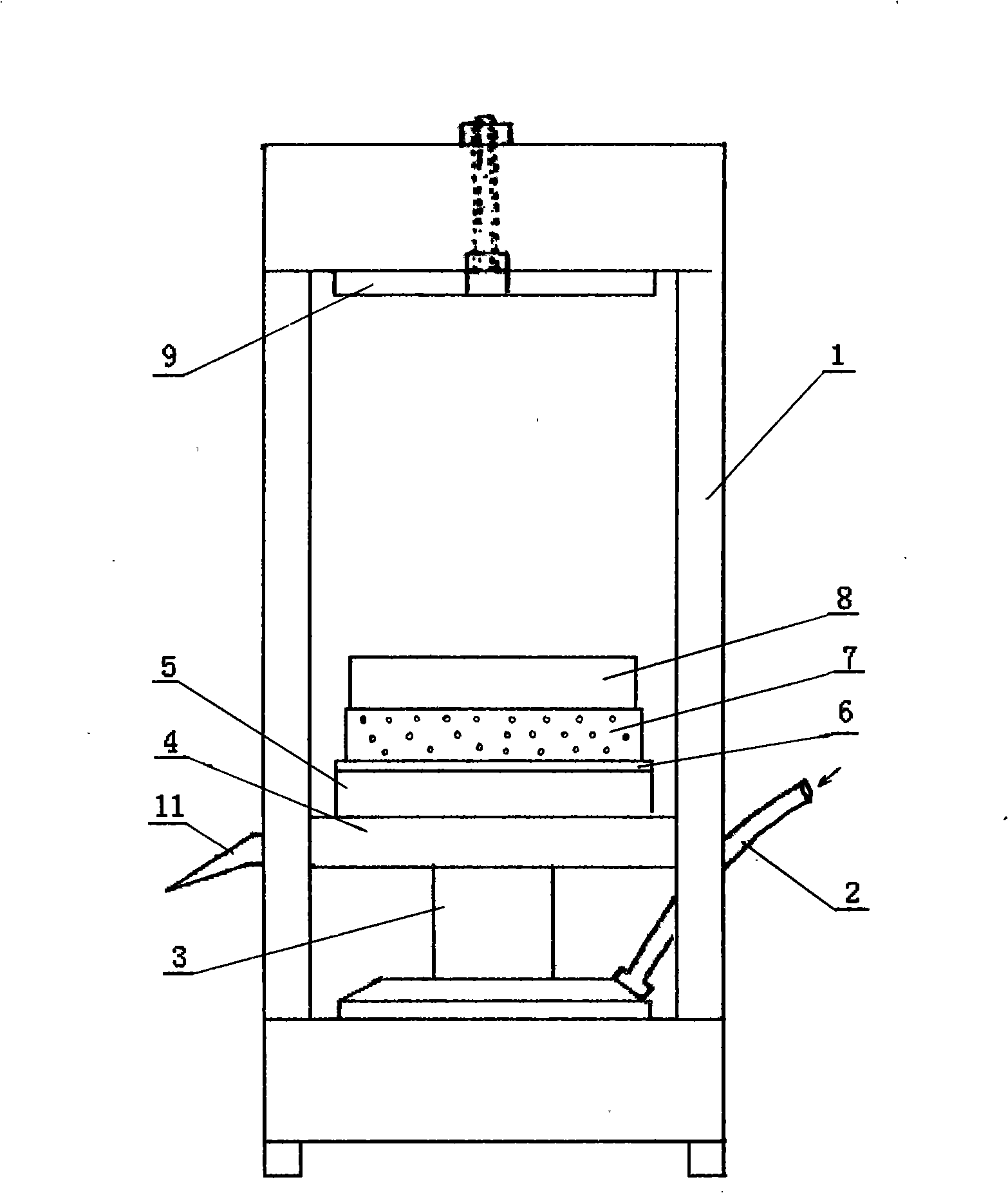

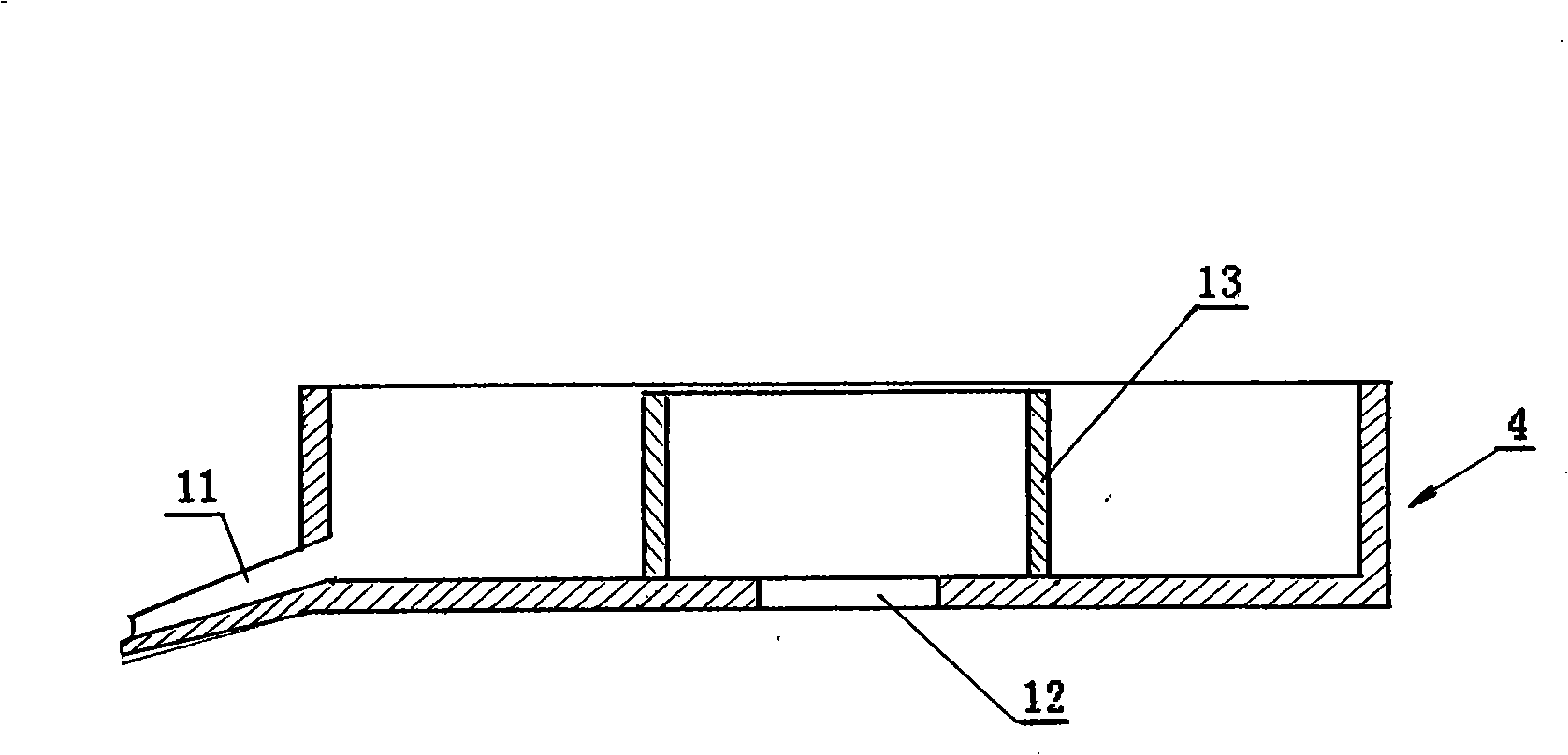

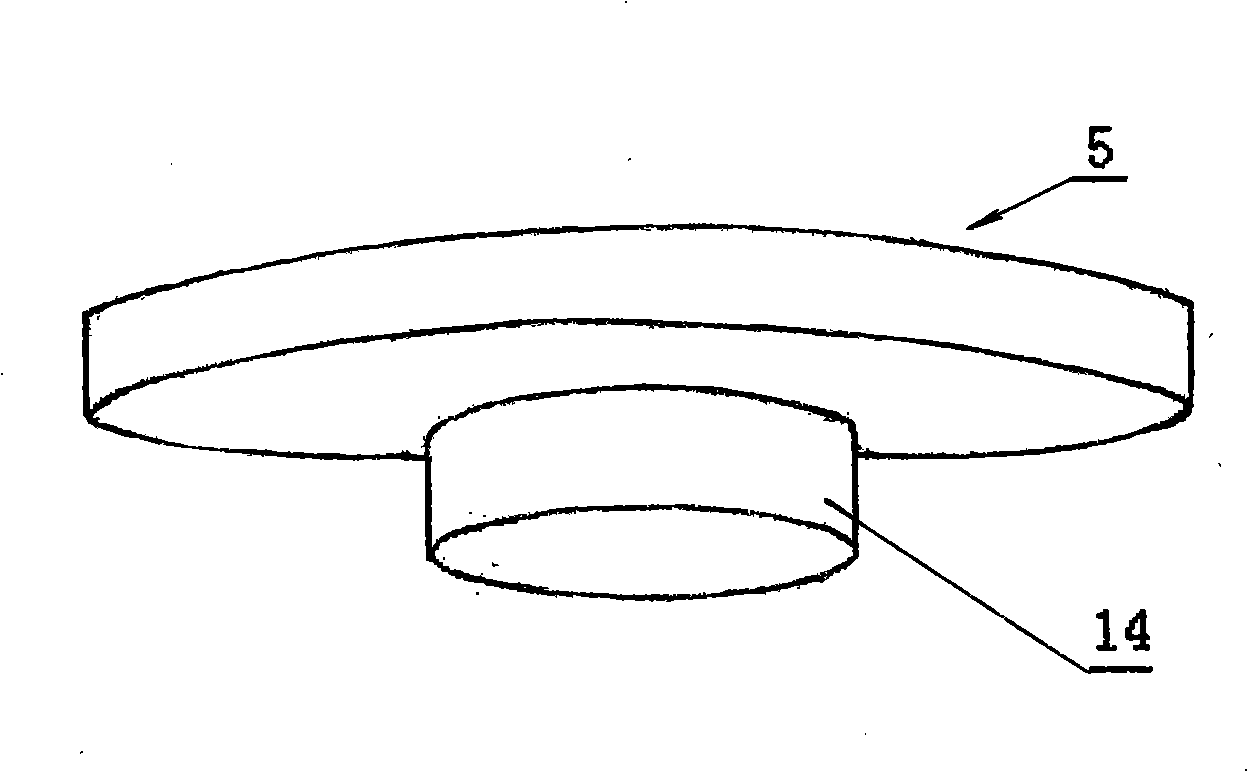

[0032] The invention relates to a device for extracting peanut oil and retaining kernels, a process thereof and a method for preparing defatted protein powder. The peanut oil extraction and kernel retention equipment of the present invention includes a support 1, a hydraulic equipment and an oil extraction system. The hydraulic equipment is located at the bottom of support 1, including hydraulic oil pipe 2, hydraulic oil cylinder and piston 3. The oil pressing system consists of oil receiving pan 4, lower top plate 5, oil flow plate 6, pressing ring 7, pressure plate 8 and upper top plate 9 in sequence. . The hydraulic oil cylinder is located at the lower part of the support 1, and the hydraulic oil is input from the hydraulic oil pipe 2 to control the work of the piston 3. The piston 3 passes through the piston through hole 12 in the oil pan 4, and is pressed against the bottom retaining ring 14 of the upper lower top plate 5. The retaining ring 14 functions to limit the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com