Halogenated arene degraded by aluminum oxide

A technology of aluminum oxide and halogenated aromatics, applied in organic decomposition, chemical instruments and methods, etc., can solve problems such as long-distance global migration, and achieve the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The aluminum oxide amorphous powder is ground, roasted, sieved and dried. Place 2mg of hexachlorobenzene and 200mg of alumina amorphous powder at 1.09cm 3 Mix well in an airtight container and react at 300°C for 1 hour. The residue after the reaction was extracted with n-hexane, and the organic phase was extracted with pure water to wash away the water-soluble impurities. The obtained n-hexane solution was detected by GC / MS to analyze the organic products after the dechlorination reaction, indicating that hexachlorobenzene had been eliminated. Completely dechlorinated. After the remaining solid matter was dried, the inorganic compounds were analyzed by X-ray diffraction, which indicated that the residue was Al 2 o 3 , AlCl 3 Wait.

Embodiment 2

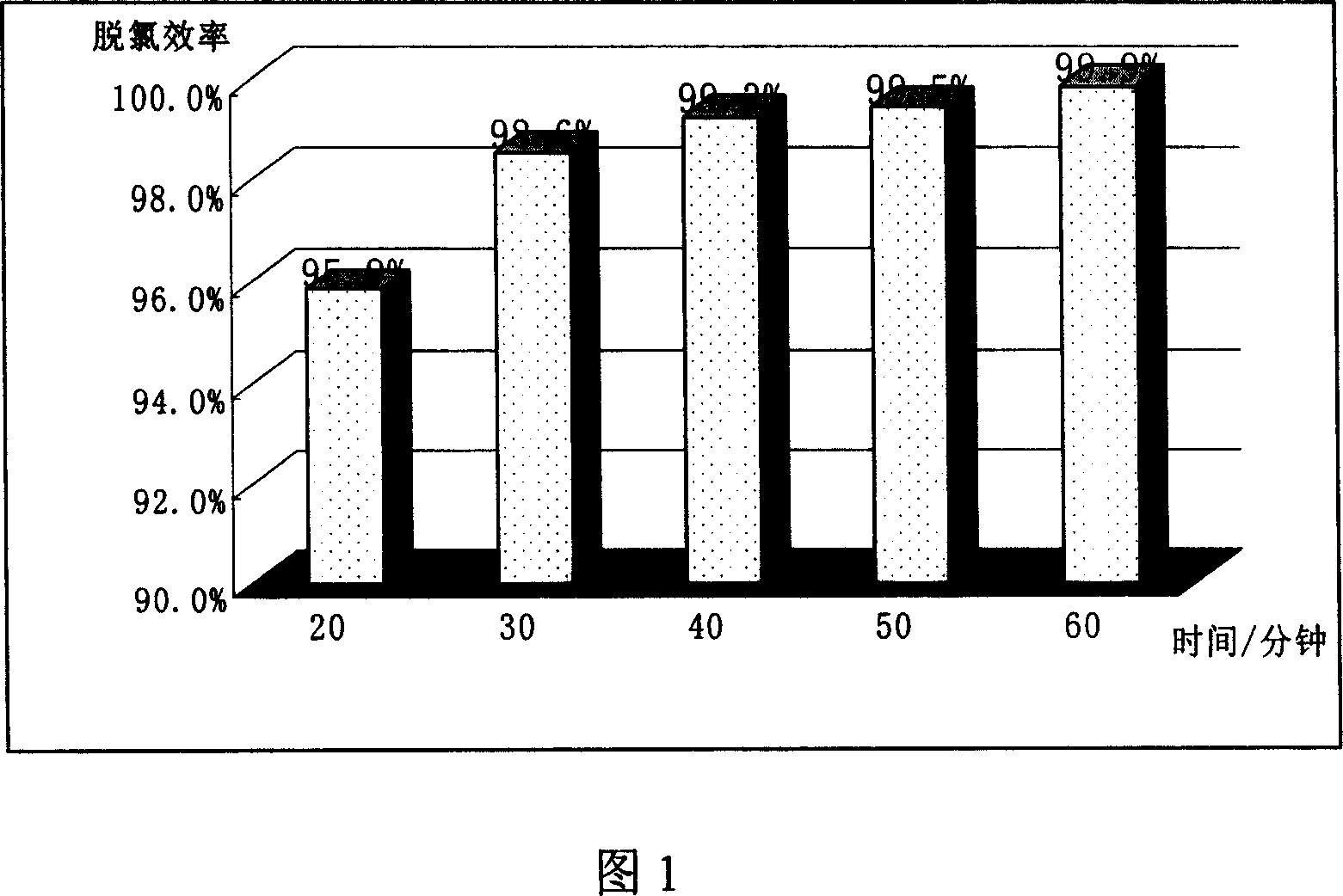

[0023] The aluminum oxide amorphous powder is ground, roasted, sieved and dried. Place 2mg of hexachlorobenzene and 200mg of alumina amorphous powder at 1.09cm 3 Mix well in a closed container and react at 300°C. The reaction times are 20 minutes, 30 minutes, 40 minutes, 50 minutes, and 60 minutes. The residue after the reaction was extracted with n-hexane, and the organic phase was extracted with pure water to wash away the water-soluble impurities, and the obtained n-hexane solution was detected by GC / MS to analyze the organic products after the dechlorination reaction. After analysis and calculation, the dechlorination efficiencies at 20 minutes, 30 minutes, 40 minutes, 50 minutes and 60 minutes are respectively 95.9%, 98.6%, 99.3%, 99.5% and 99.9%. The relationship between dechlorination efficiency and reaction time is shown in Figure 1.

Embodiment 3

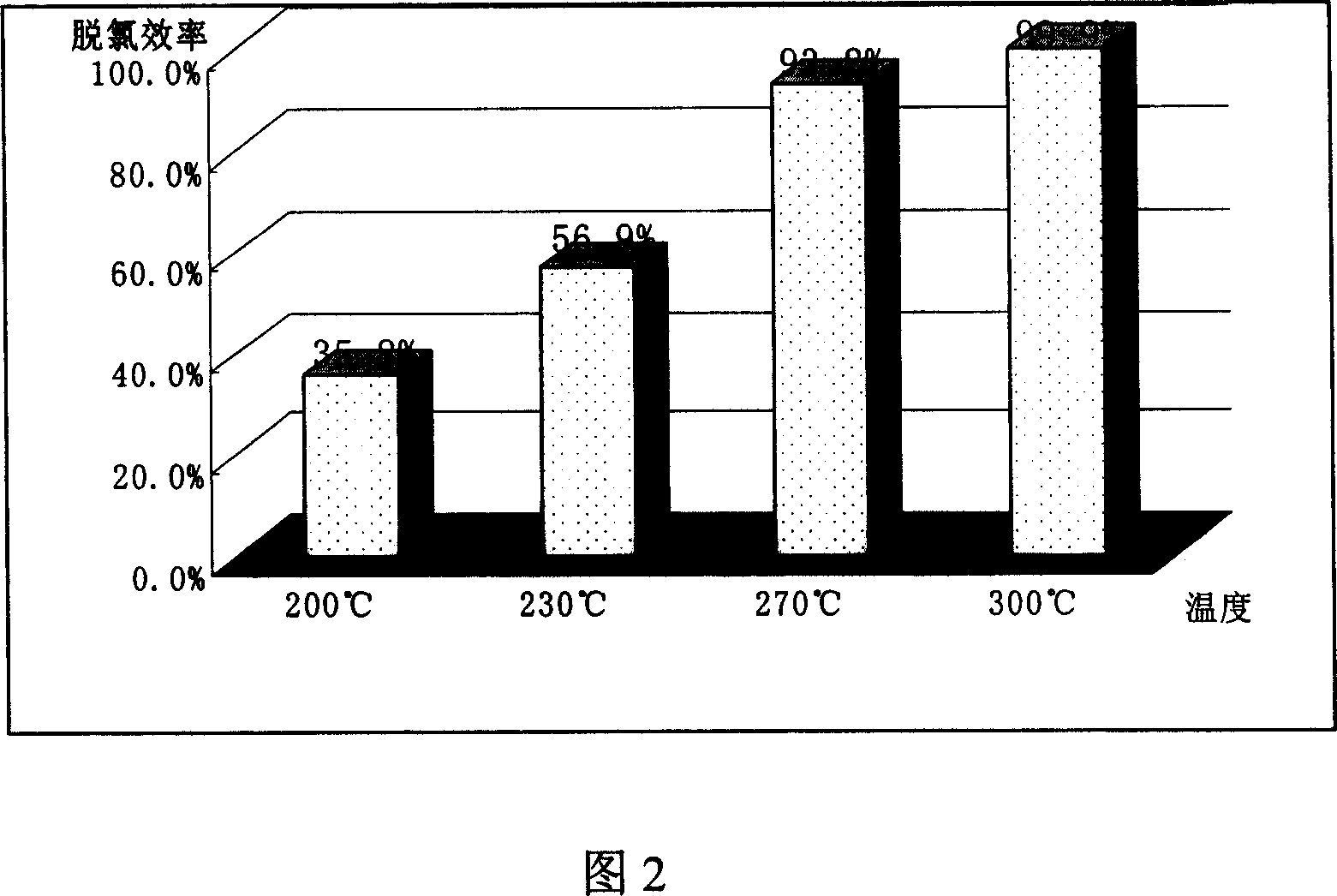

[0025] The aluminum oxide amorphous powder is ground, roasted, sieved and dried. Place 2mg of hexachlorobenzene and 200mg of alumina amorphous powder at 1.09cm 3Mix well in a closed container and react at 200°C, 230°C, 270°C, and 300°C for one hour respectively. The residue after the reaction is extracted with n-hexane, and the organic phase is extracted with pure water to wash away the water-soluble Impurities, the obtained n-hexane solution was detected by GC / MS, and the organic products after the dechlorination reaction were analyzed. After analysis and calculation, the dechlorination efficiencies at 200°C, 230°C, 270°C, and 300°C were respectively 35.8%, 56.9%, 93.2%, 99.9%. The relationship between dechlorination efficiency and reaction temperature is shown in Figure 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com