Patents

Literature

94 results about "Mercury vapour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

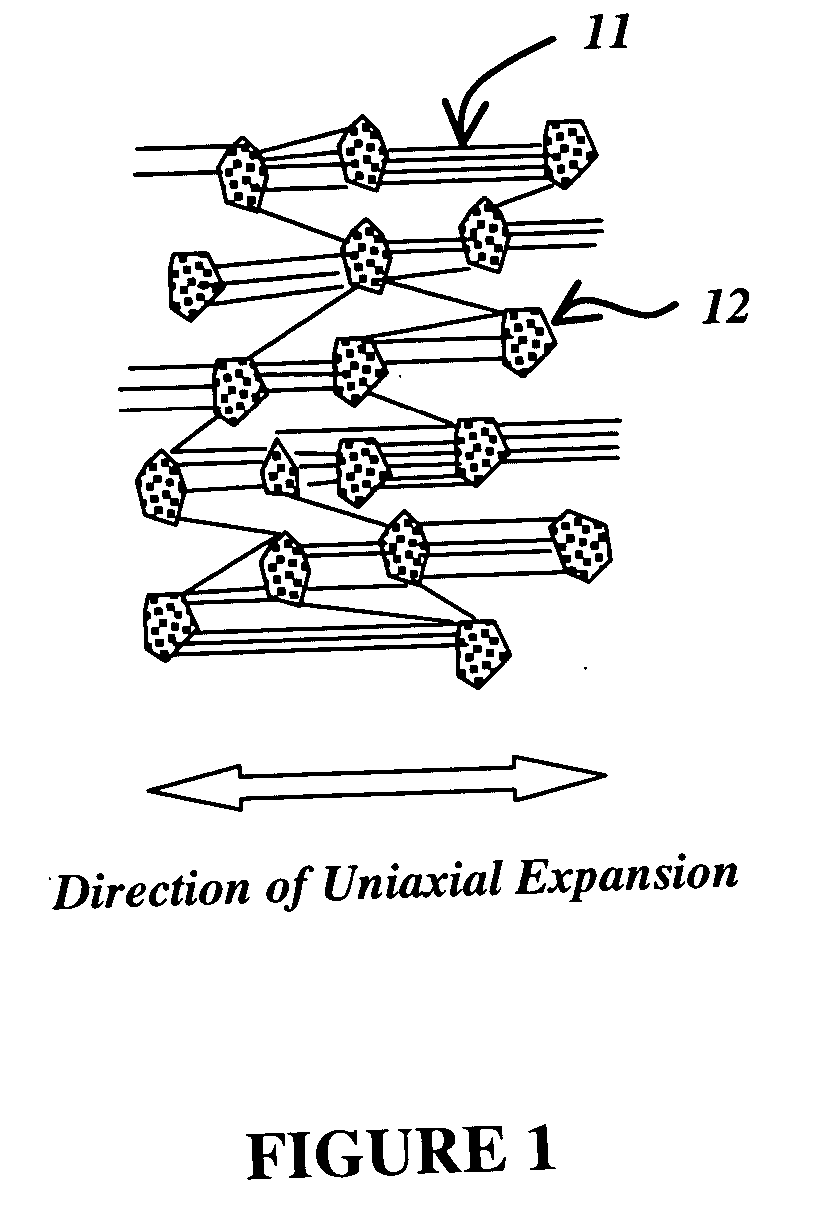

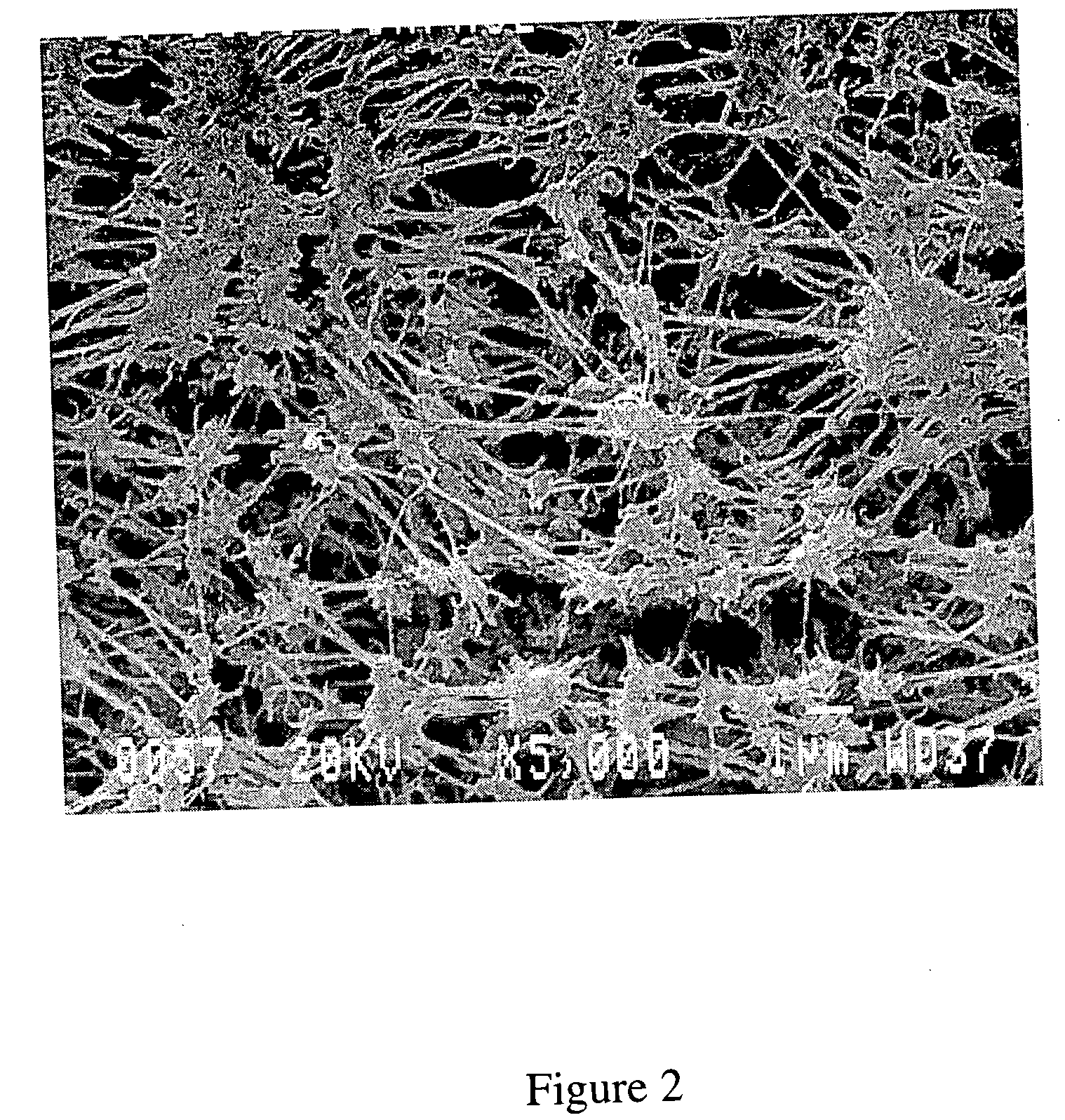

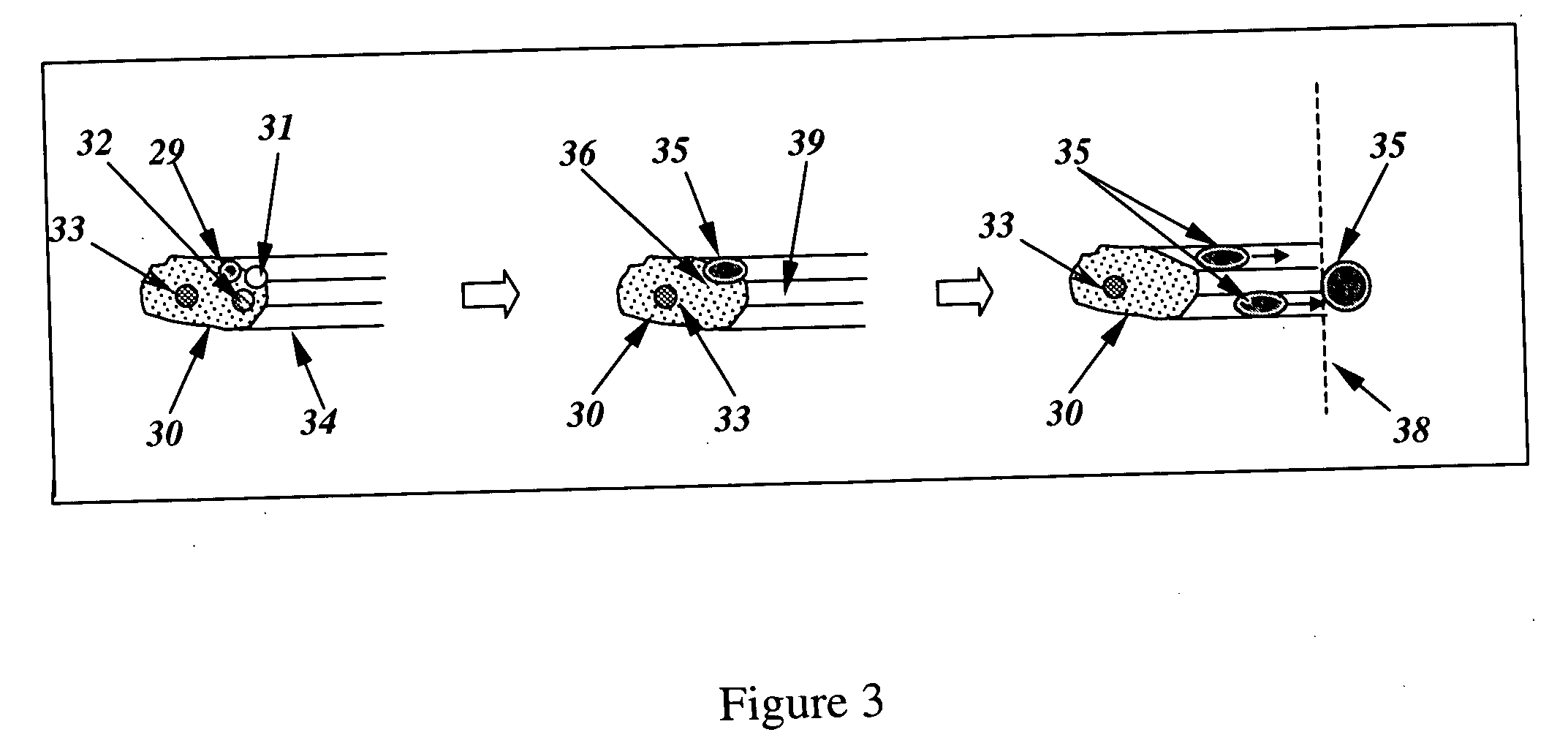

Flue gas purification process using a sorbent polymer composite material

ActiveUS20050019240A1Easy to fixImprove removal efficiencyGas treatmentNitrogen compoundsSorbentFluoropolymer

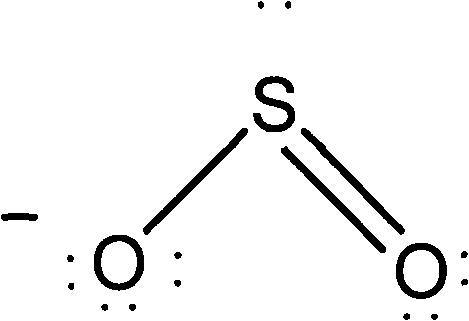

This invention provides a process of removing sulfur oxides, mercury vapor, and fine particulate matters from industrial flue gases that contain such pollutants. The pollutants are removed by modules, which contain microporous adsorbent (i.e., sorbent) material that is held within a polymer matrix. The preferred polymers are fluoropolymers. The composite material that contains the microporous absorbent material held within a polymer matrix removes sulfur oxides by converting them into high concentration sulfuric acids. It also removes mercury vapor by chemically adsorbing the mercury into the matrix. It also removes fine particulate matters by surface filtration. The sulfuric acid that is produced inside the composite material is automatically expelled onto the external surfaces of the composite material and is drained into an acid reservoir together with the fine particulate matters which are washed from the external surfaces of the composite material by the constant dripping of the sulfuric acid along the external surfaces of the composite material.

Owner:WL GORE & ASSOC INC

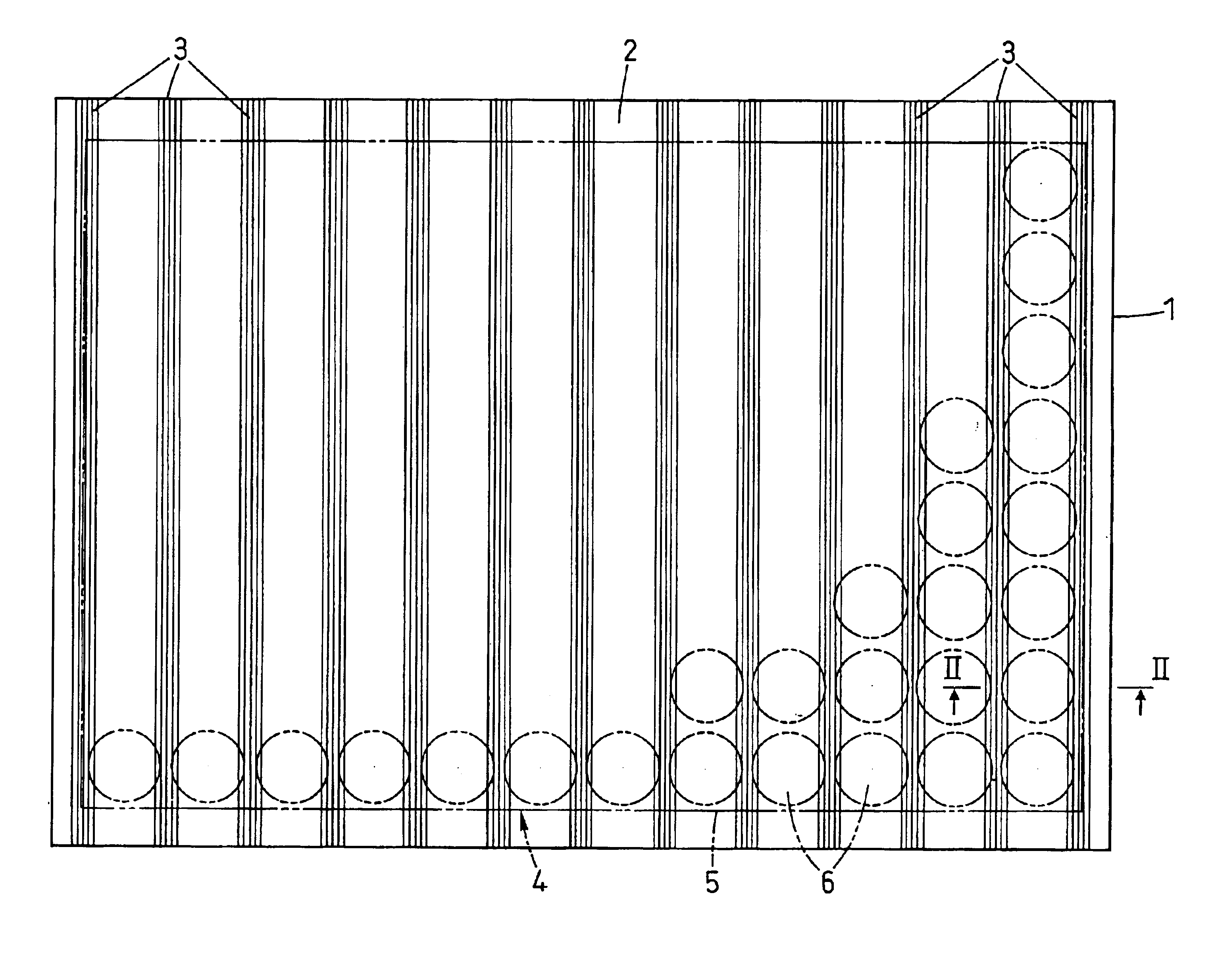

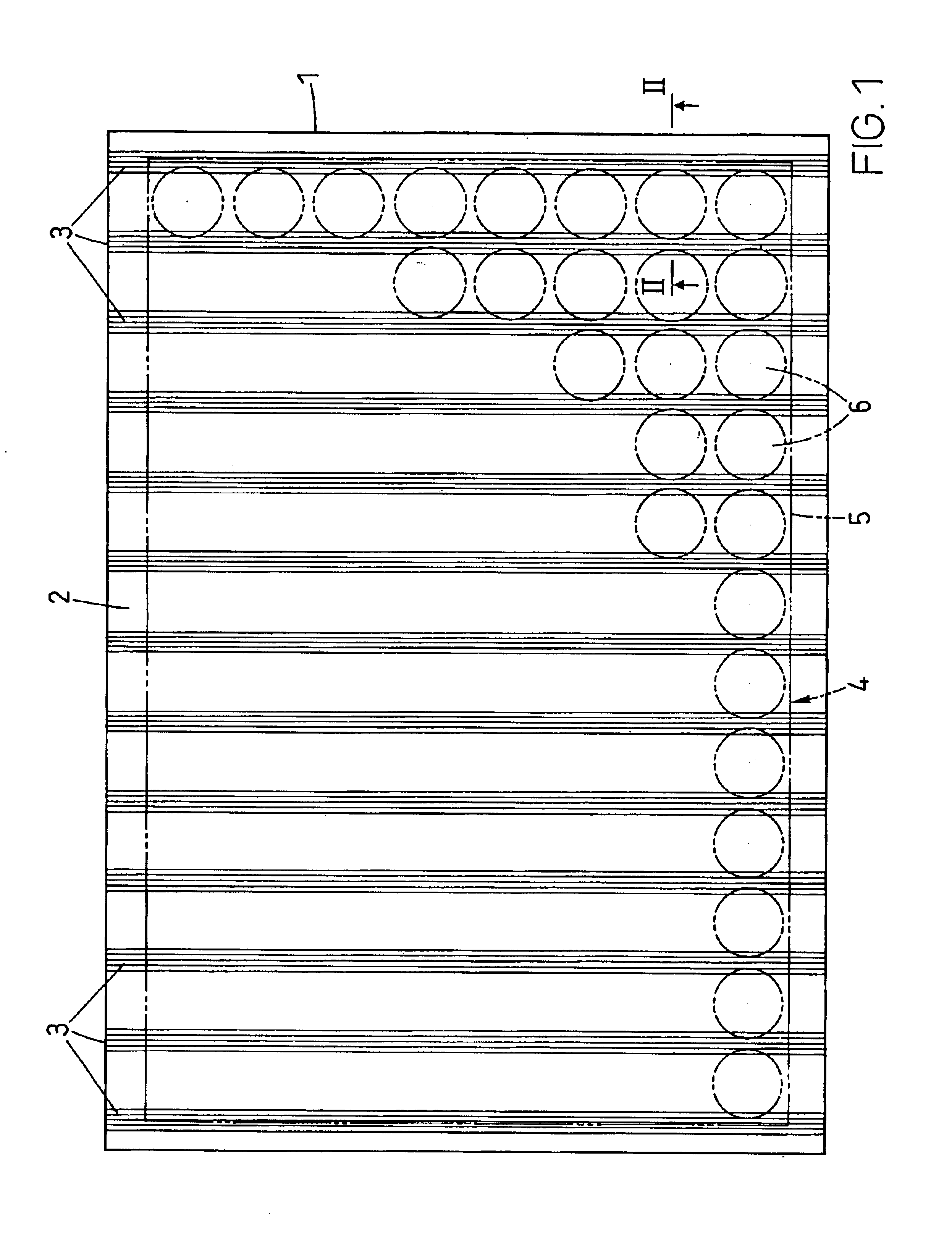

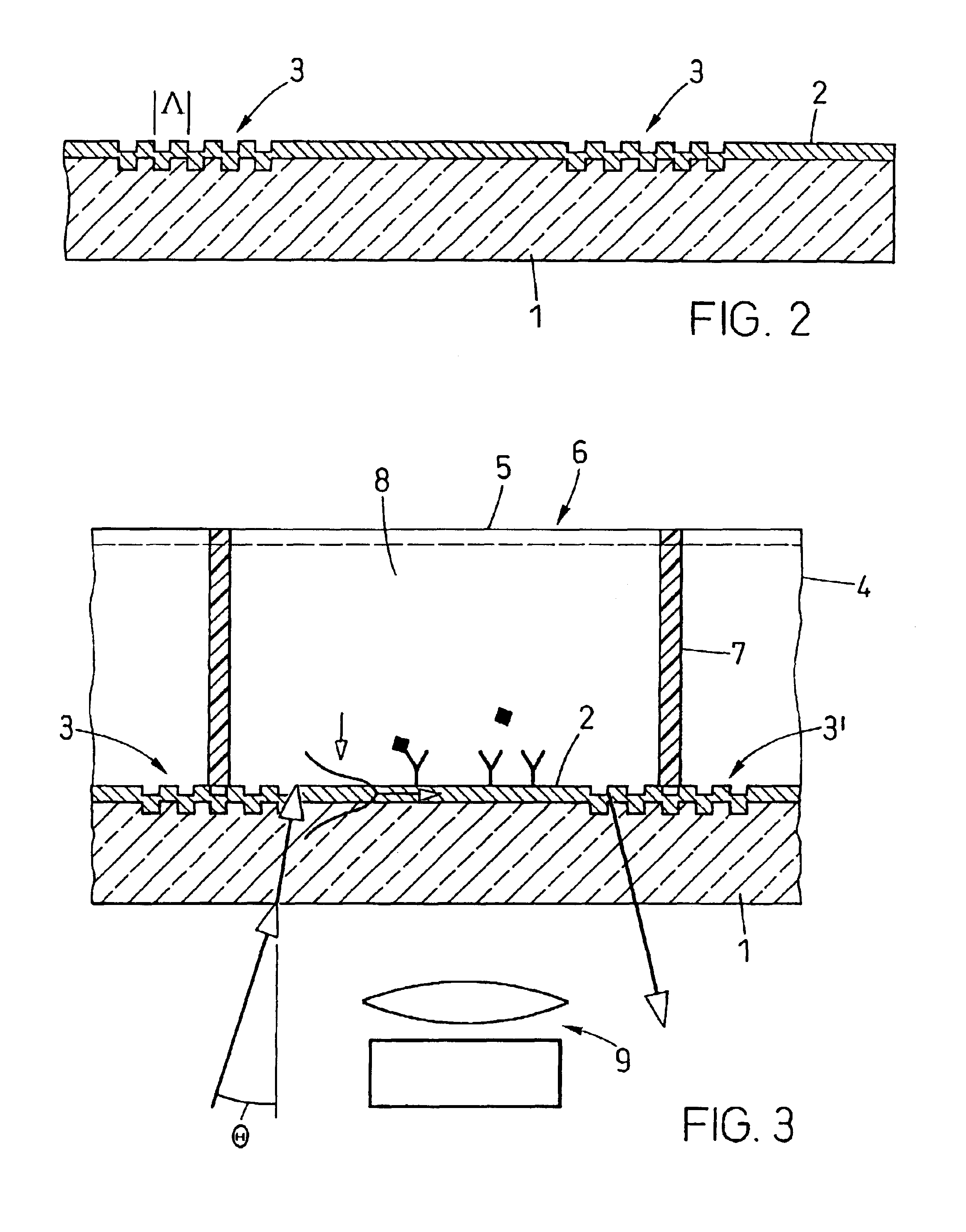

Method for producing a grid structure, an optical element, an evanescence field sensor plate, microtitre plate and an optical communication engineering coupler as well as a device for monitoring a wavelength

InactiveUS6873764B2Improve accuracyLow effortCladded optical fibreMaterial analysis by observing effect on chemical indicatorGratingPulsed DC

Owner:OERLIKON TRADING AG TRUEBBACH

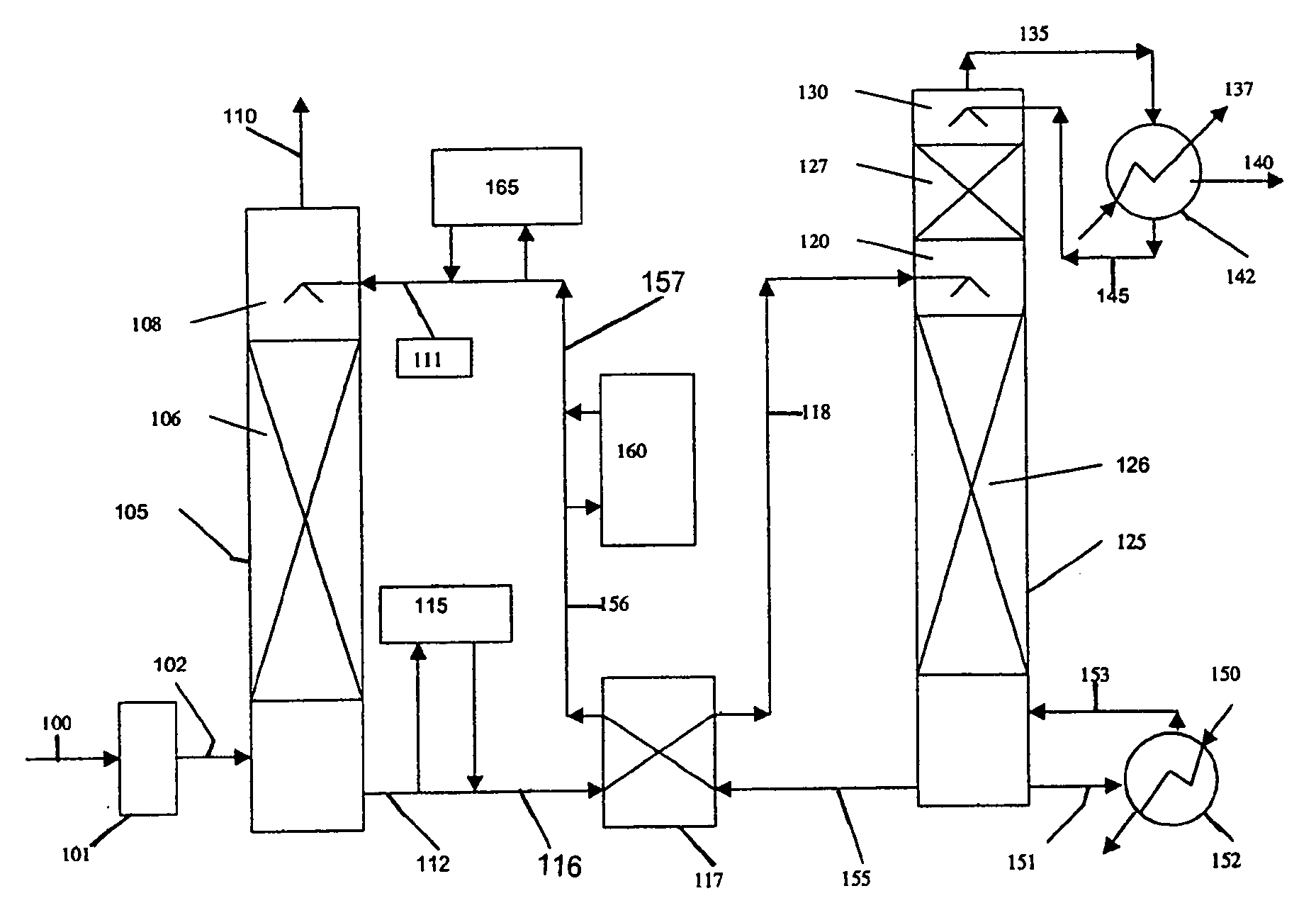

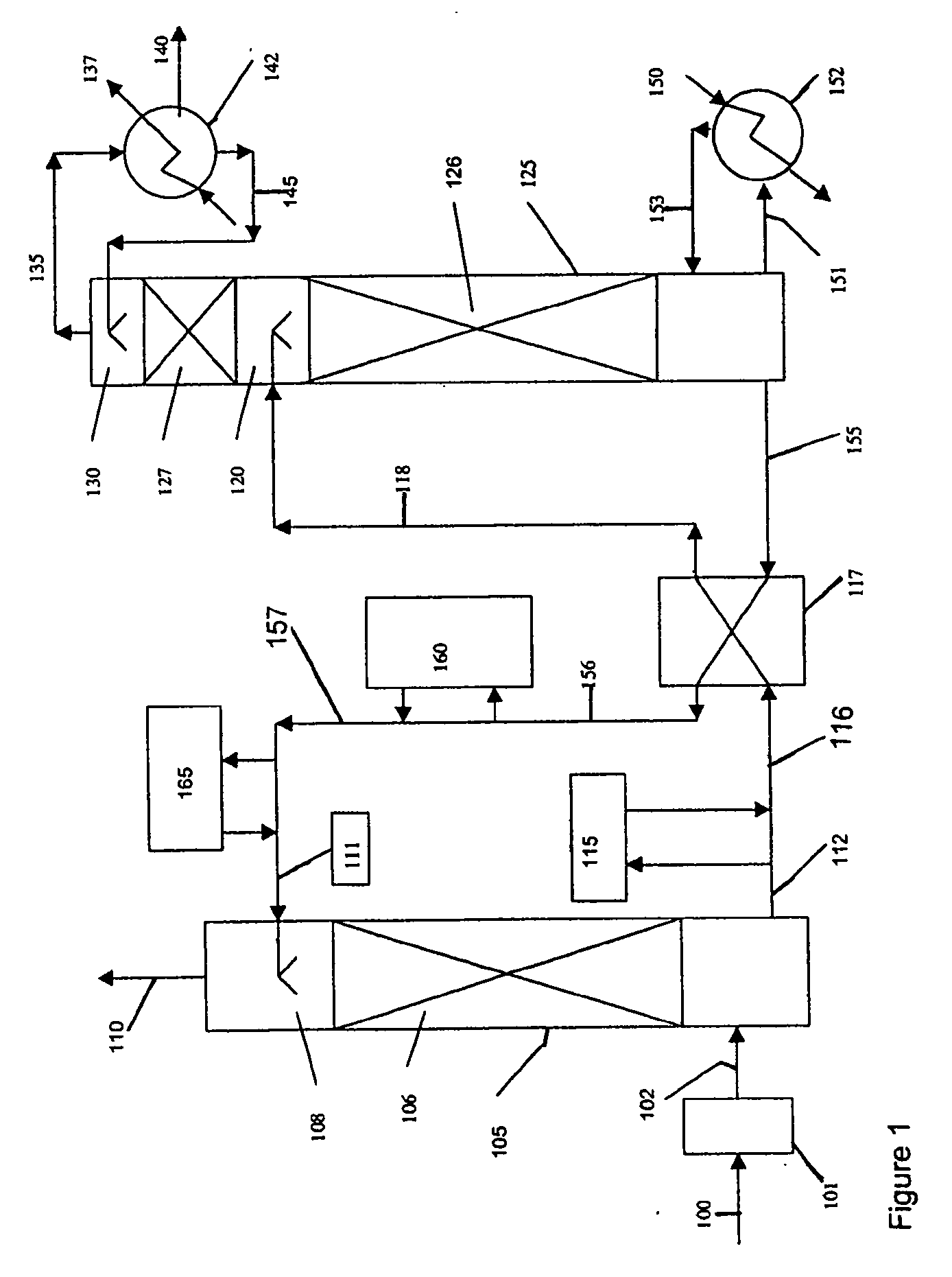

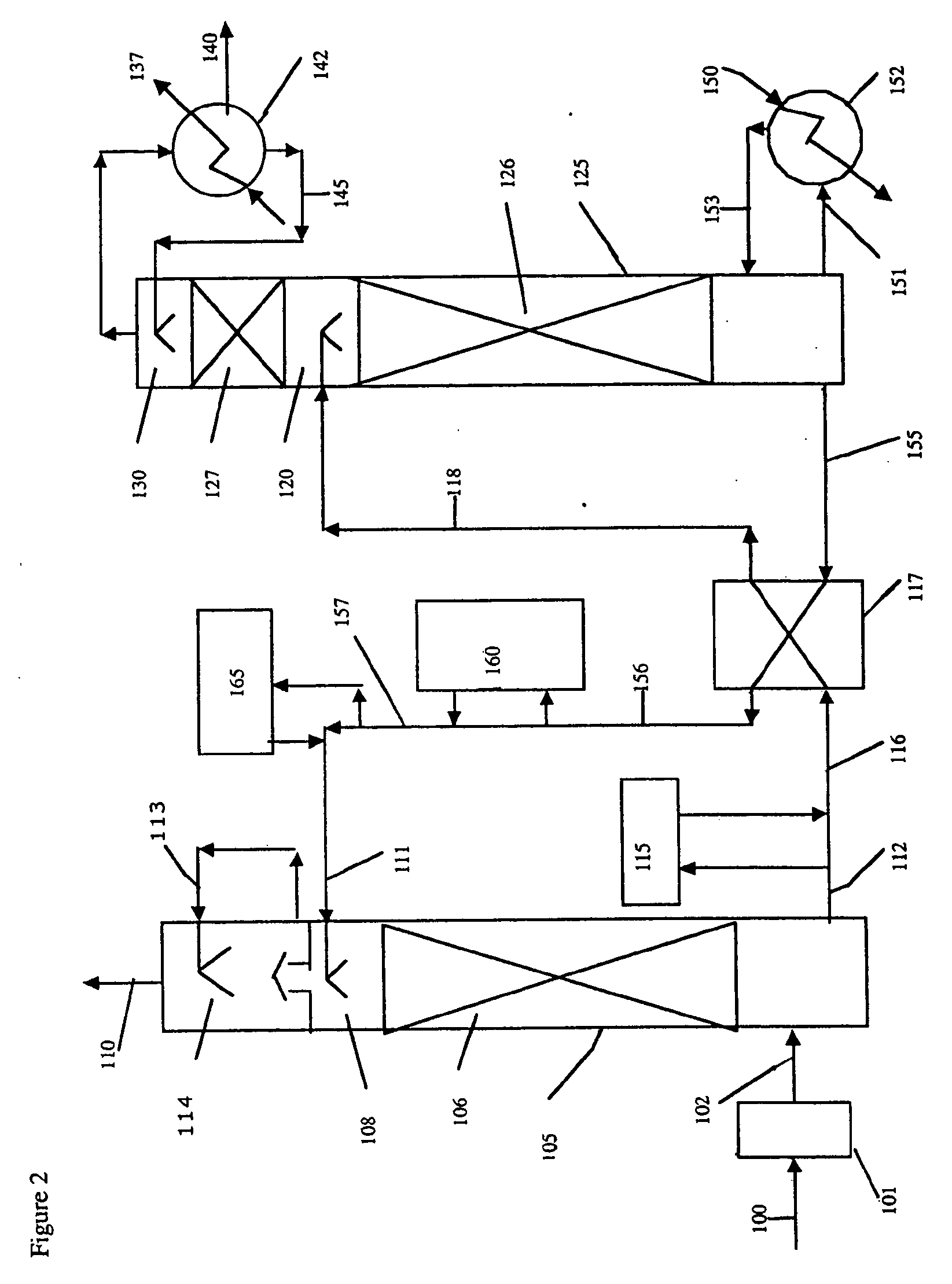

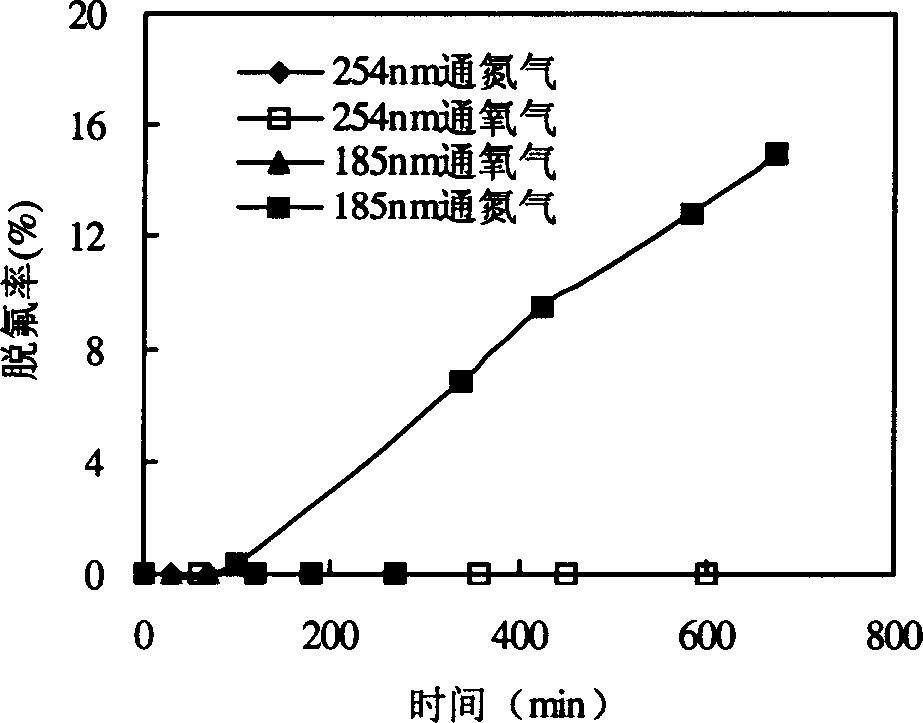

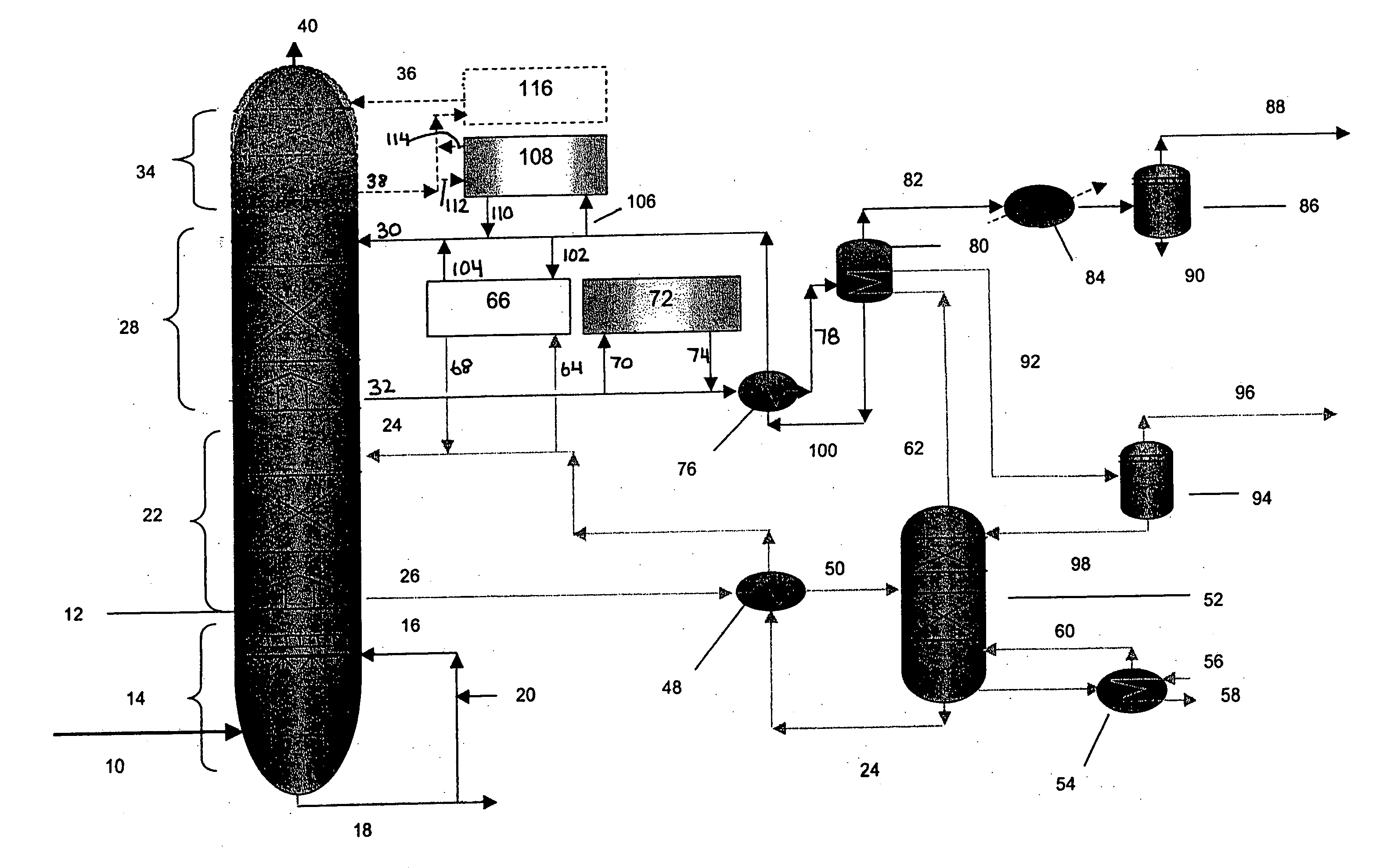

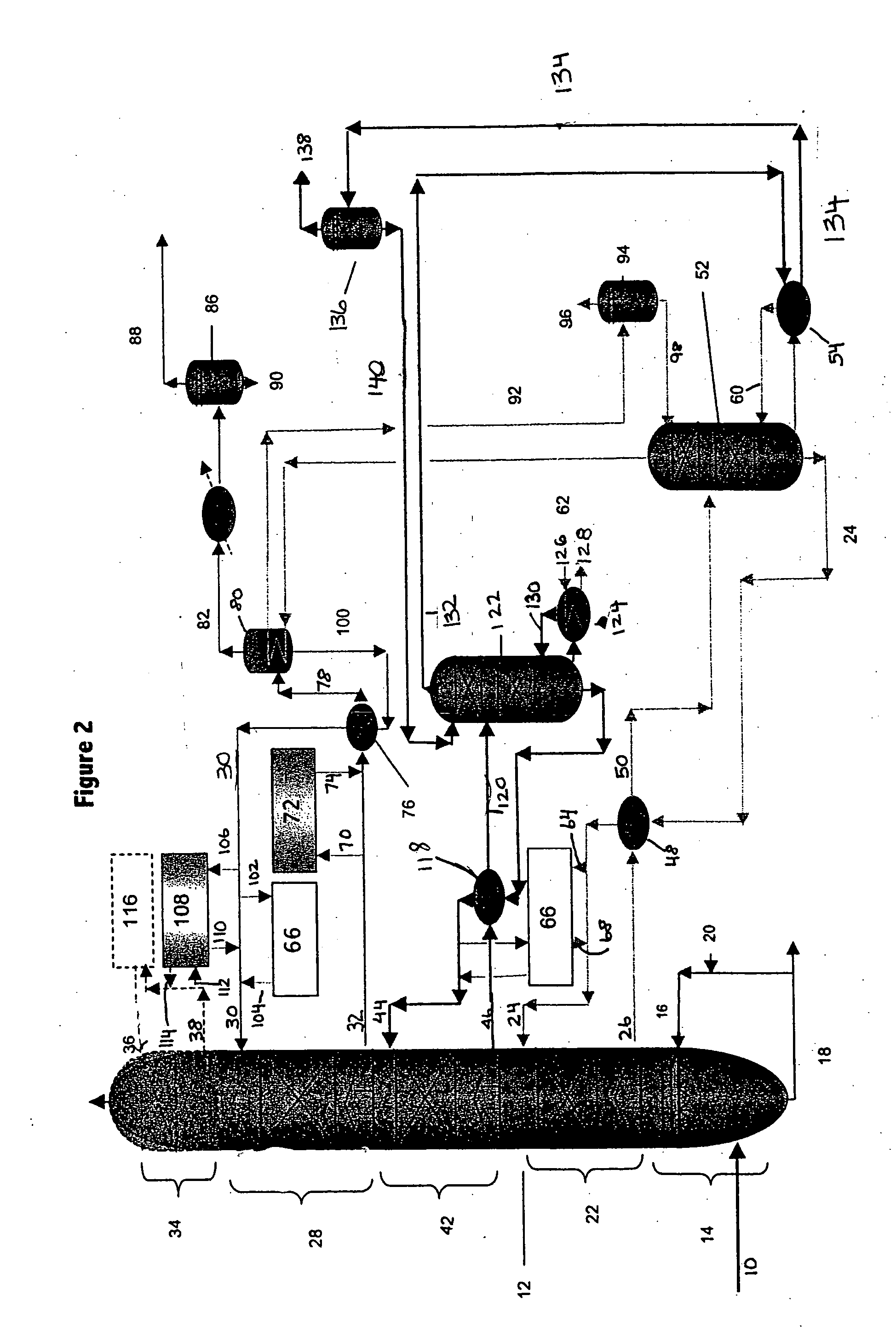

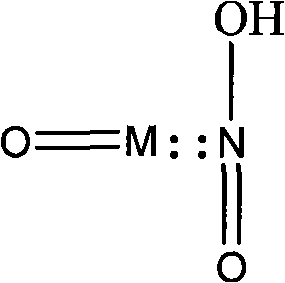

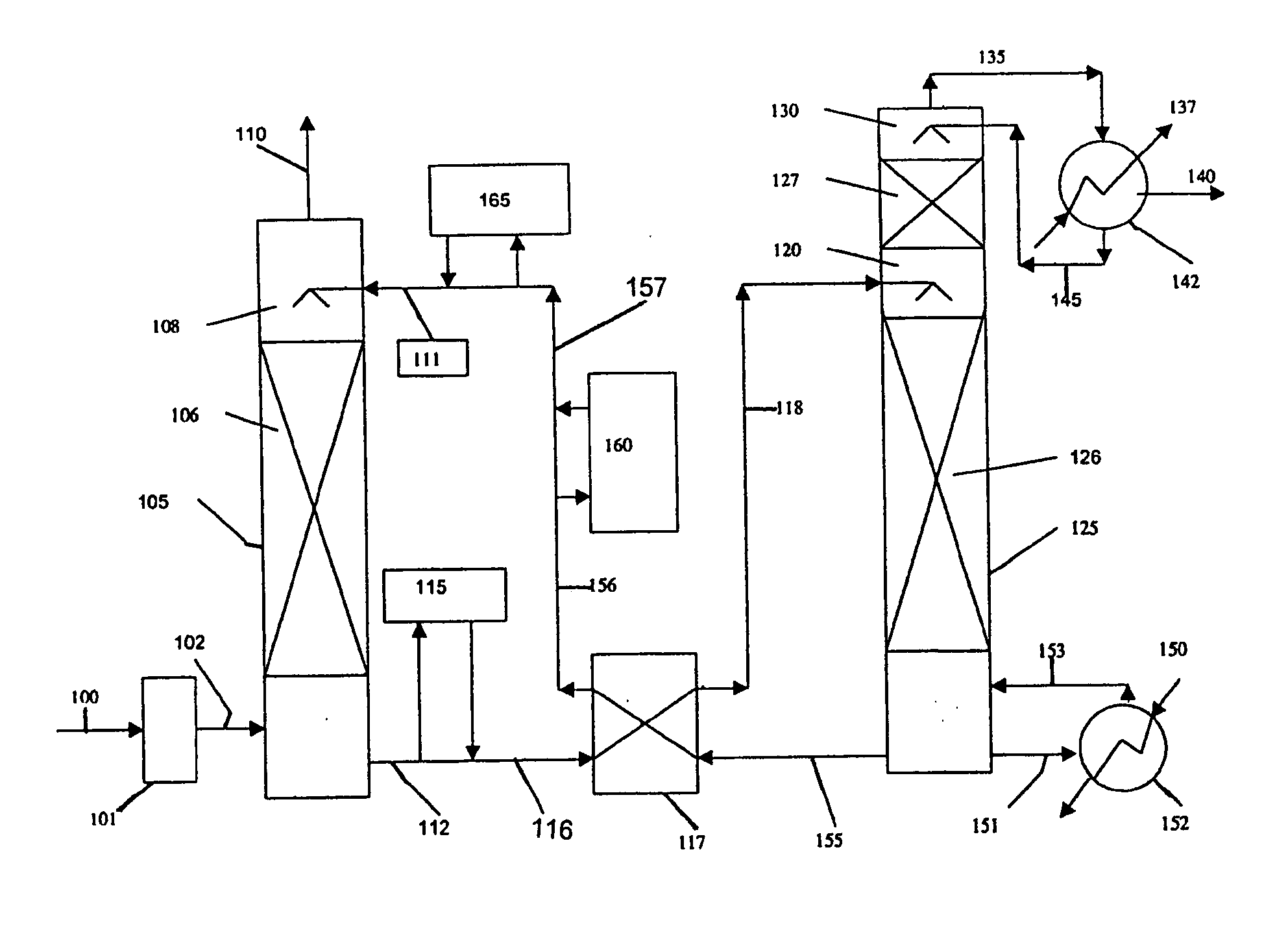

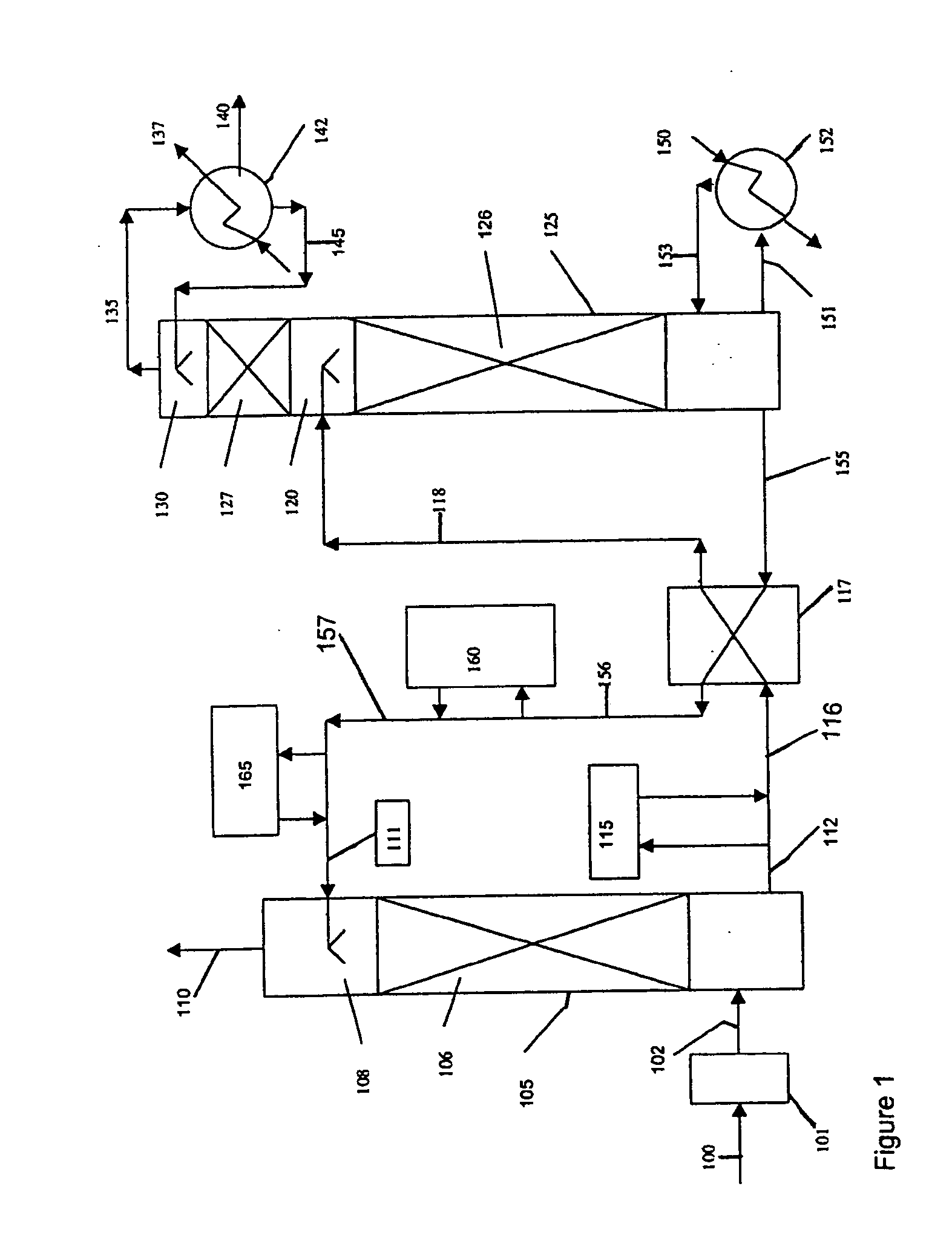

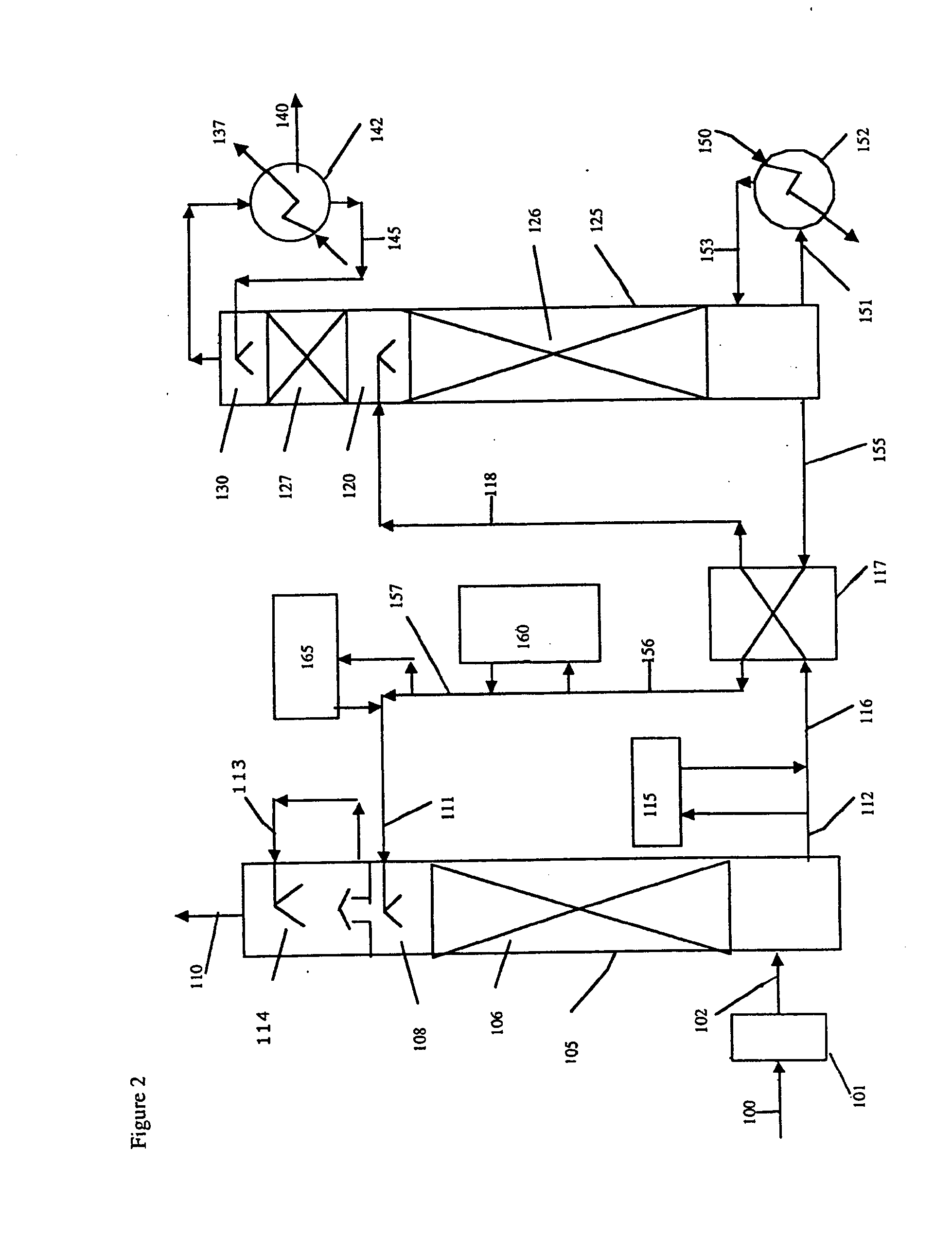

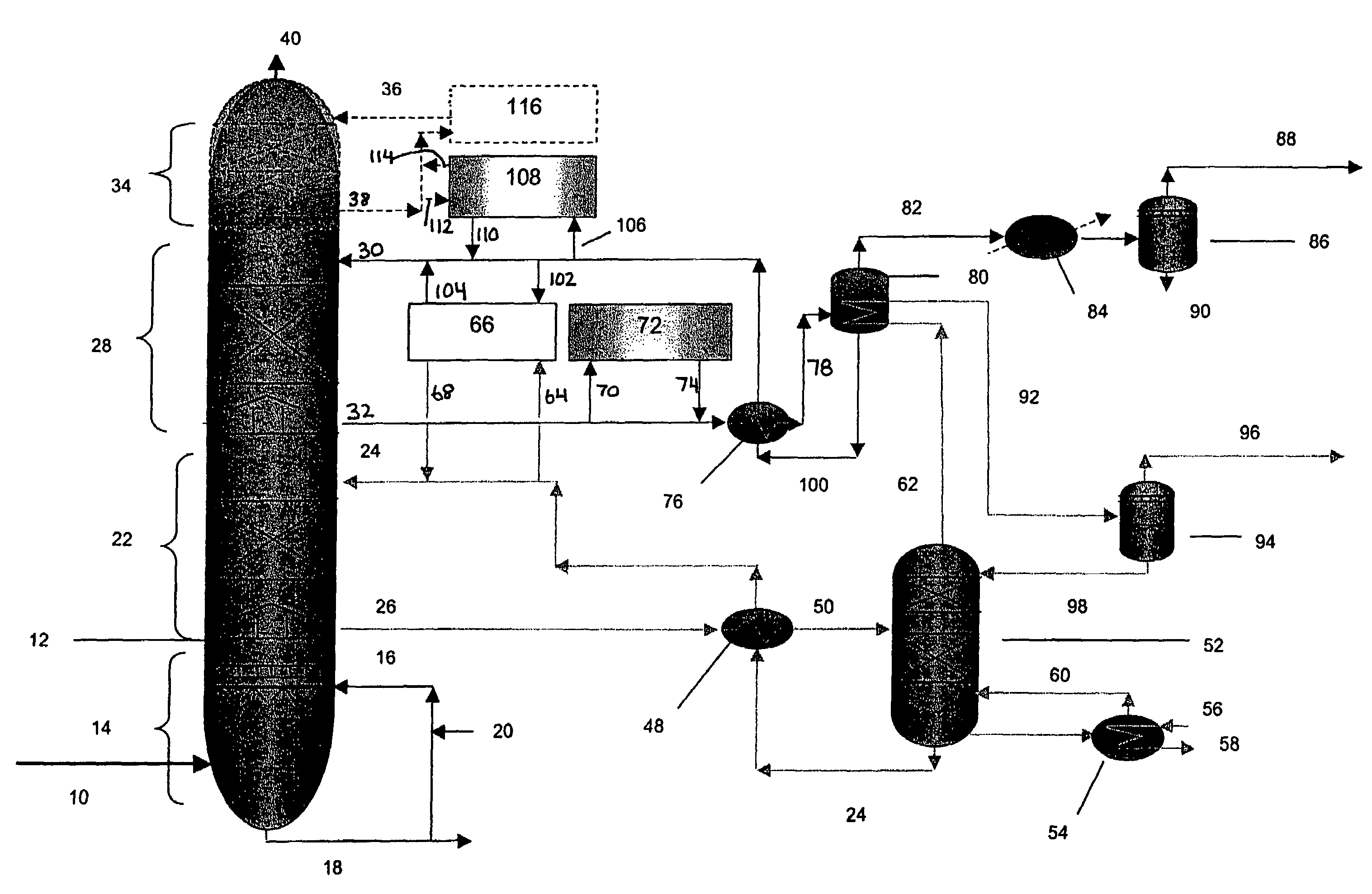

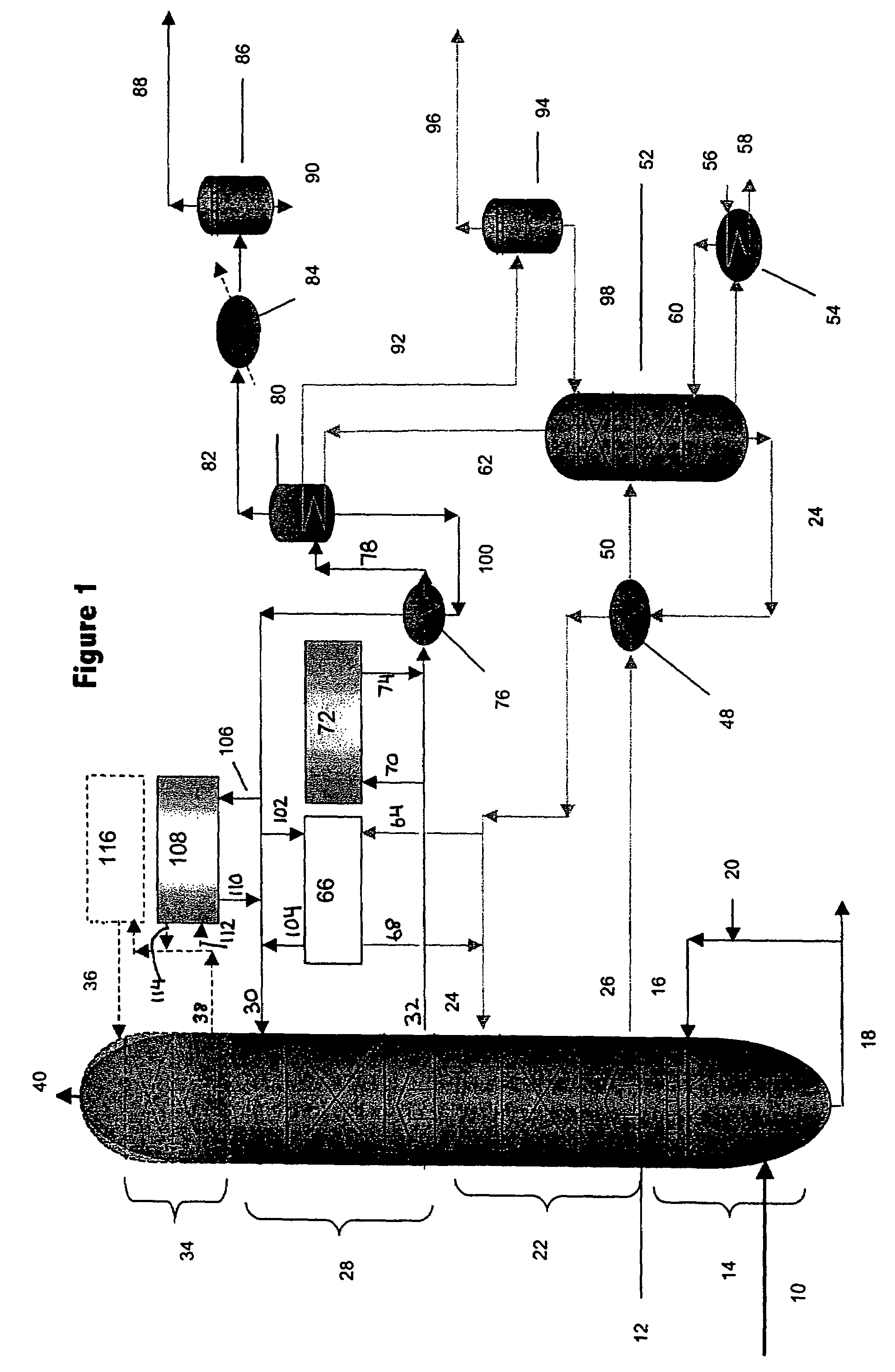

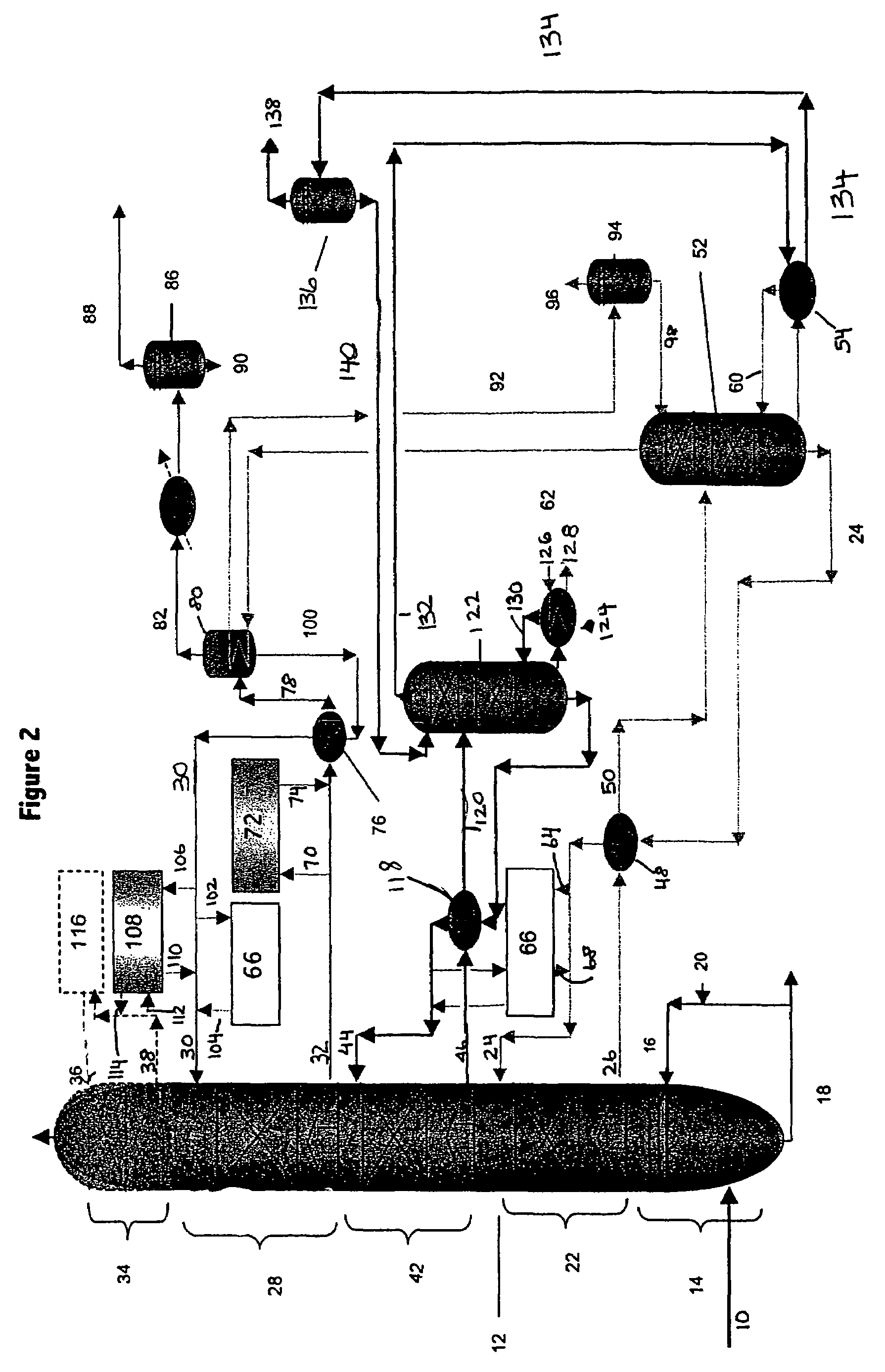

Method and apparatus for NOx and Hg removal

InactiveUS20060021506A1Prevent buildupReduce probabilityNitrogen compoundsUsing liquid separation agentCyclic processMercury vapour

A cyclic process for the removal of NOx from a NOx containing feed gas, and optionally removal mercury vapour and / or sulfur dioxide is provided. A process is also provided by which an iron chelate absorbent may be thermally regenerated.

Owner:CANSOLV TECH INC

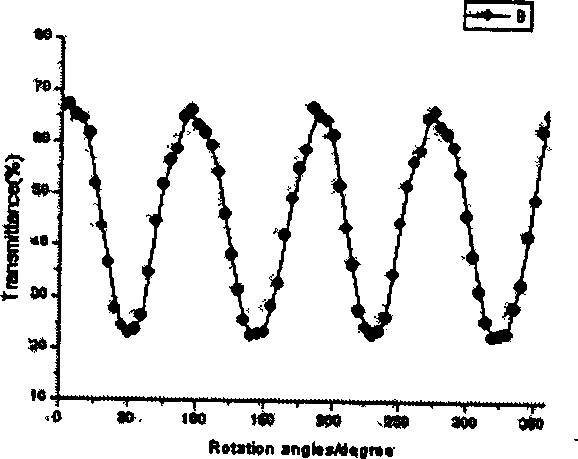

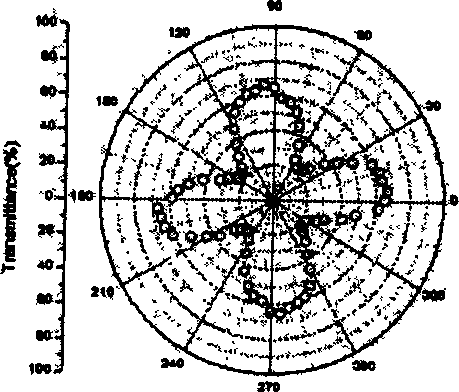

Liquid crystal oriented film, and preparation and use thereof

The present invention relates to a liquid crystal photooriented film using polysilsesquioxans as base material, its composition material includes polysilsesquioxane whose side chain contains photosensitive group and its composition material, and the connection mode of the side chain and base body has two kinds of vertical connection type and side connection type. Said oriented layer can be made up by using polysilsesquioxane whose side chain contains photosensitive group and its composition material in the general solvent, for example toluene, xylene, ethyl alcohol or tetrahydrofuran solutionby means of spin-coating process. The coated base plate after whic his irradiated by polarized long-wave UV light ejected by optical system formed from ball mercury vapour lamp, quartz condensing prism and polarizer can produce vertical and planar two kinds of orientation effect with preinclined angle for induction, and said preinclined angle can be up to 6 deg.

Owner:INST OF CHEM CHINESE ACAD OF SCI

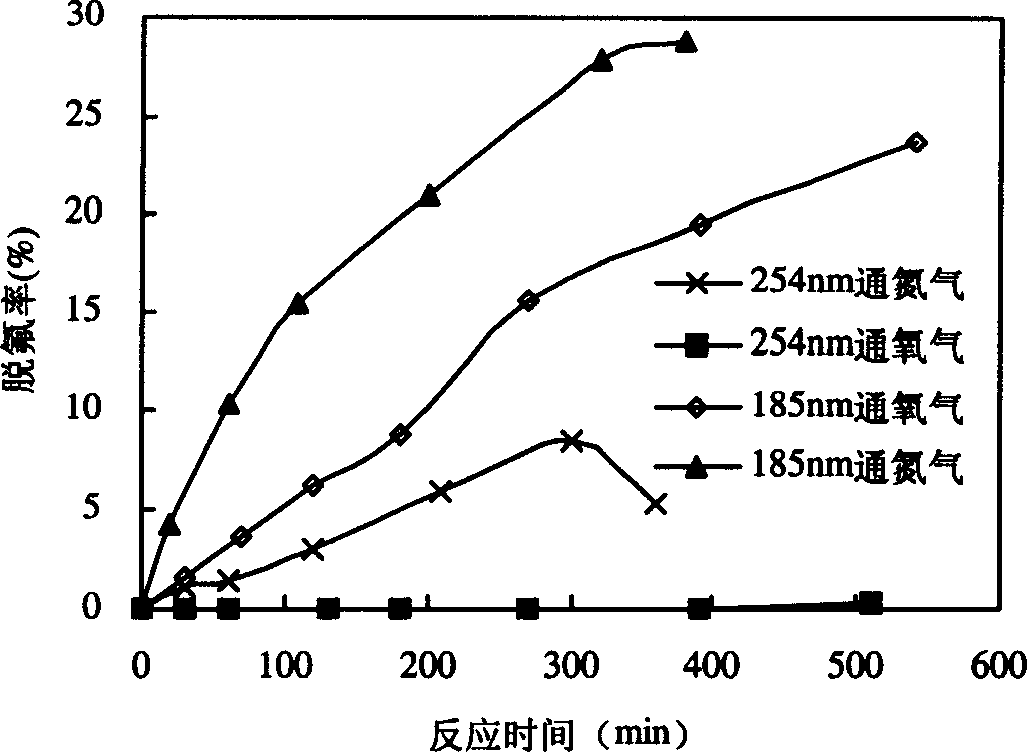

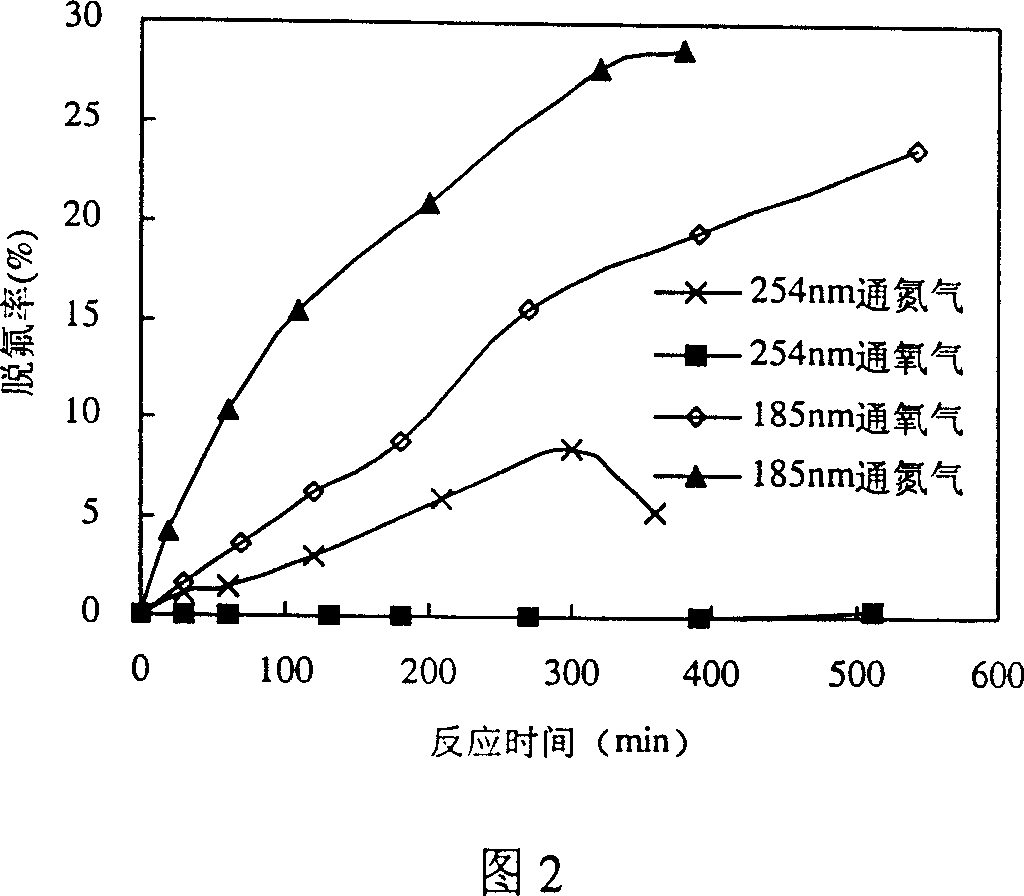

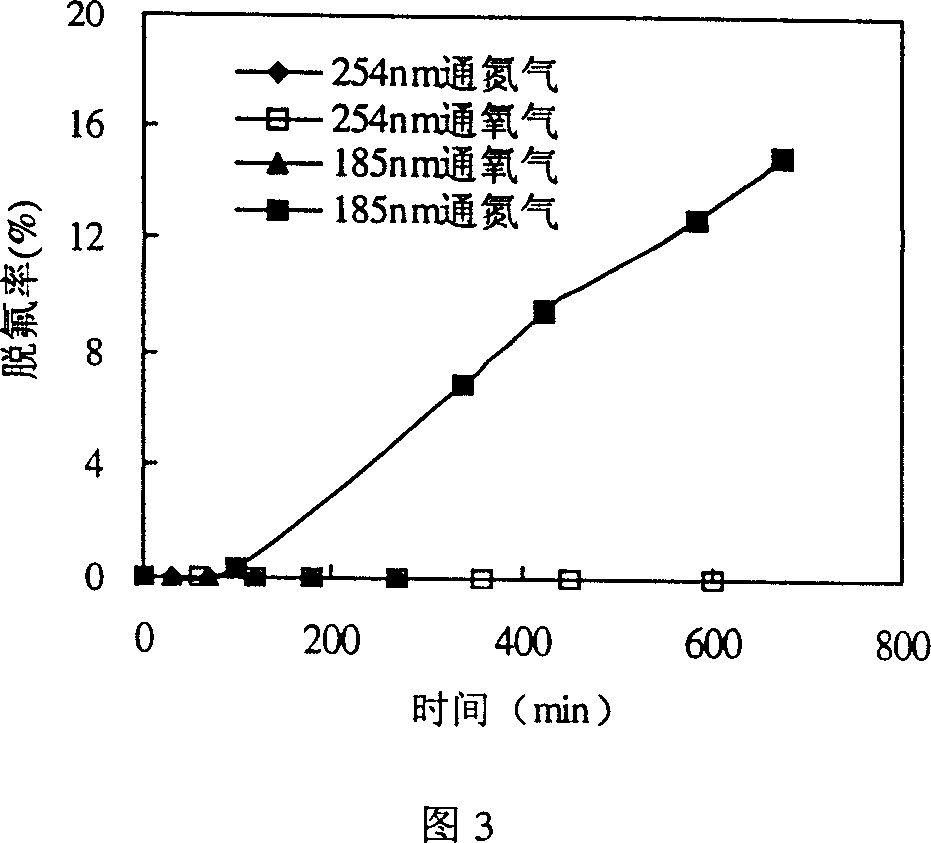

Method for defluorinating and degrading complete fluorine substituted compounds

InactiveCN1680219ALow toxicityEasy to handleSolid waste disposalOrganic decompositionUltravioletLaser light

A defluorinating and degrading method of fluorine substituted compound is characterized by vacuum ultraviolet irradiating PFOS and PFOA etc. fluorine substituted compound at anaerobic condition, defluorinating reacting fluorine substituted compound at irradiation of 185nm ultraviolet mercury vapour light or 172nm xenon quasi molecule laser light, inducing protective inert gas or reducing gas for realizing anaerobic condition, or adding reducing substance or semiconductor catalyst with high conducting band energy level during reacting process to improve defluorinating and decomposing ratio. It achieves simple operation and non-toxic.

Owner:TSINGHUA UNIV

Filtration Media for the Removal of Mercury From Flue Gas Emissions

InactiveUS20090101015A1High mercury removal levelEfficient removalGas treatmentSilicaFiltrationTrapping

Filtration materials comprising heat-treated metal-doped precipitated silica or silica gel materials with sulfur-containing functional silane surface treatments are provided. Such materials exhibit excellent mercury removal properties from flue gas emissions through the trapping of mercury vapors within a smokestack (or other like site). The metal dopant and the sulfur-containing functional silane components applied to the surface of the target metal-doped gels effectuate the desired mercury reactions to permit capture thereof. In combination, such components permit versatile utilization in either a fixed bed configuration or through a dynamic mercury removal procedure. Methods of using and specific filter apparatuses are also encompassed within this invention.

Owner:J M HUBER CORP

Method for comprehensively recovering mercury and selenium from metallurgical slag

InactiveCN104498722ALow costNo emissionsProcess efficiency improvementElemental selenium/telluriumMetallurgical slagHydroxylamine

The invention discloses a method for comprehensively recovering mercury and selenium from metallurgical slag and belongs to the field of metallurgy. The method comprises following steps: grinding the metallurgical slag to the range of 130-150 microns, blending the metallurgical slag with quick lime accounting for 10-30% of the metallurgical slag and roasting at a temperature ranging from 750 to 900 DEG C for 6-8 hours; collecting dust from mercury-containing vapor firstly by use of a cloth bag and then by virtue of cyclone, condensing the mercury vapor by use of a two-stage condensation apparatus to recovery the mercury, and returning mercurial soot and a tail gas adsorption filler to the metallurgical slag for reutilization, wherein no pollutant is emitted in the process; next, leaching selenium-containing slag by use of an oxidation solution prepared from hydrochloric acid and sodium chlorate in the ratio of 2:1, analyzing the contents of Hg<2+>, Fe<2+>, Ca<2+> and Mg<2+> in the leachate in the liquid-solid ratio of 2:1, respectively, precipitating the ions by use of sodium sulfide in the ratio of 1:1 to the total content of the ions and then filtering to remove the irons, and reducing for 2 hours by use of hydroxylamine hydrochloride, thereby obtaining the elemental selenium after washing the precipitate. The method for comprehensively recovering mercury and selenium from the metallurgical slag is high in extraction rate and prone to industrial production.

Owner:贵州重力科技环保股份有限公司

Waste gas treatment process including removal of mercury

InactiveUS20060286017A1Lower levelNitrogen compoundsUsing liquid separation agentPERMANGANATE IONMercury vapour

A process for removing contaminants from a waste gas stream comprises treating the waste gas stream to remove at least one of SO2 and NOx and to obtain a lean stream having a reduced level of at least one of SO2 and NOx and, contacting the lean gas stream with a mercury absorbent solution comprising permanganate to remove mercury vapour and to obtain a mercury lean stream and a mercury rich absorbent solution. The mercury rich absorbent solution may be subsequently treated on a batch basis to remove precipitated manganese dioxide and obtain a solution containing mercury ions.

Owner:CANSOLV TECH INC

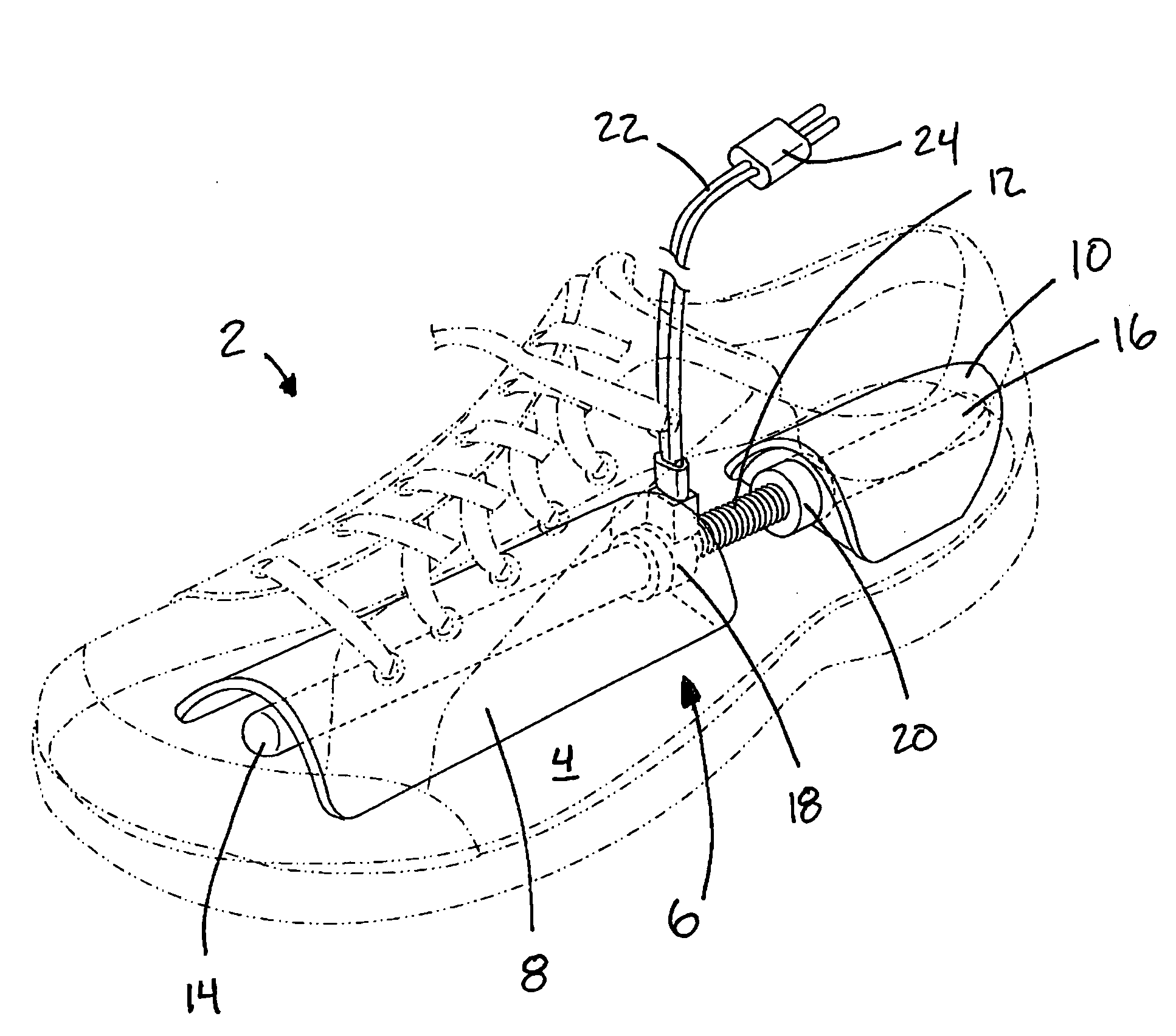

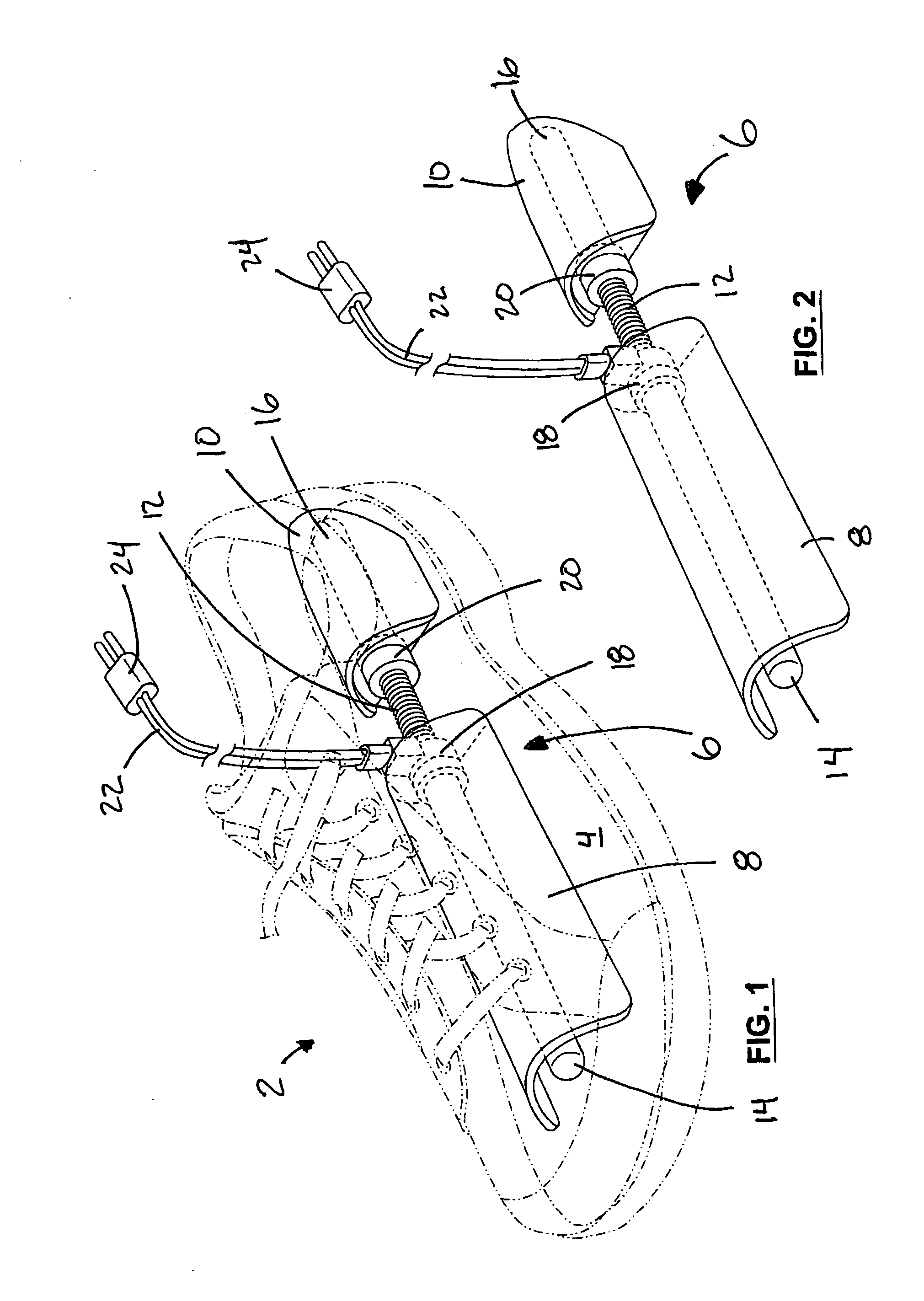

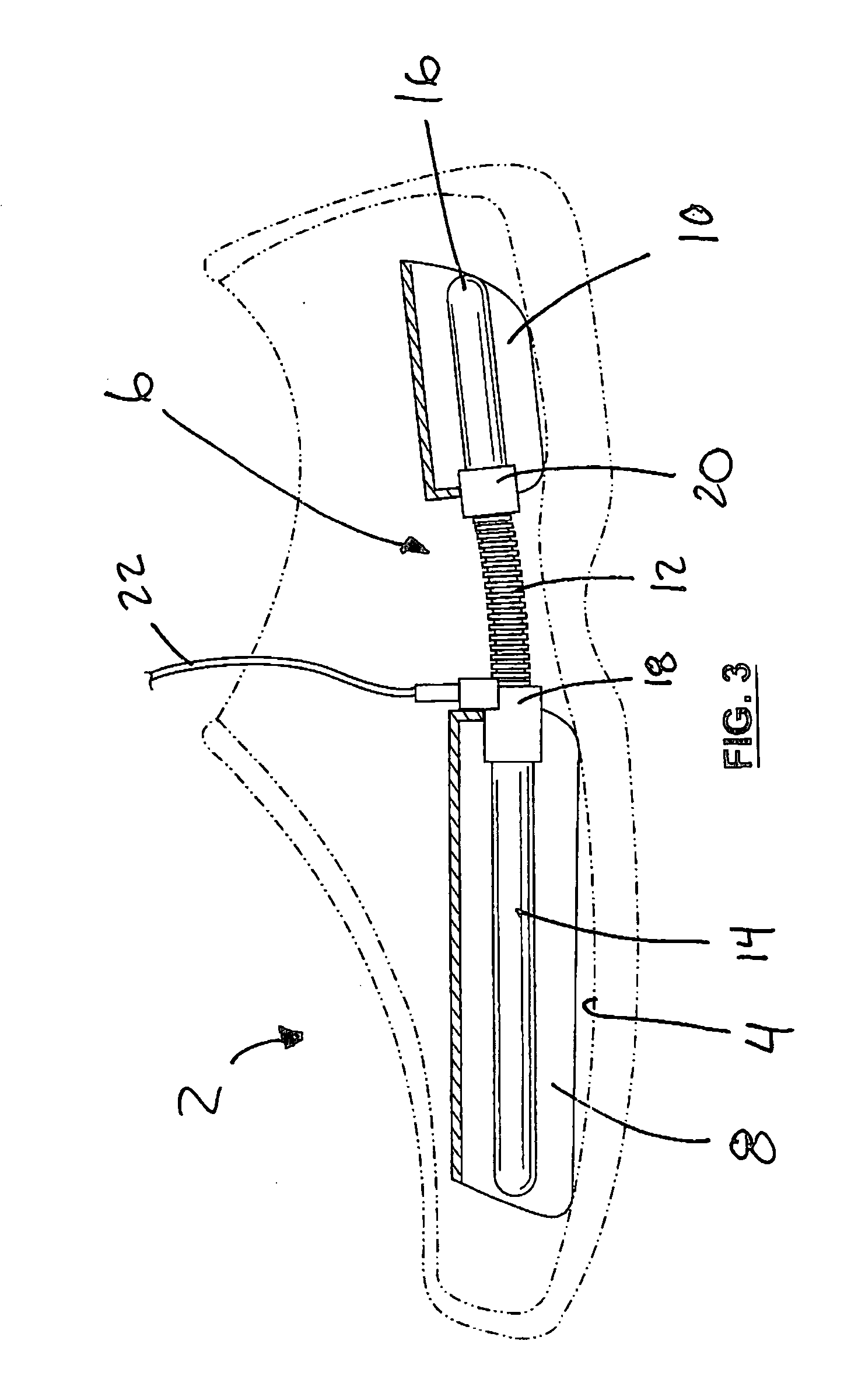

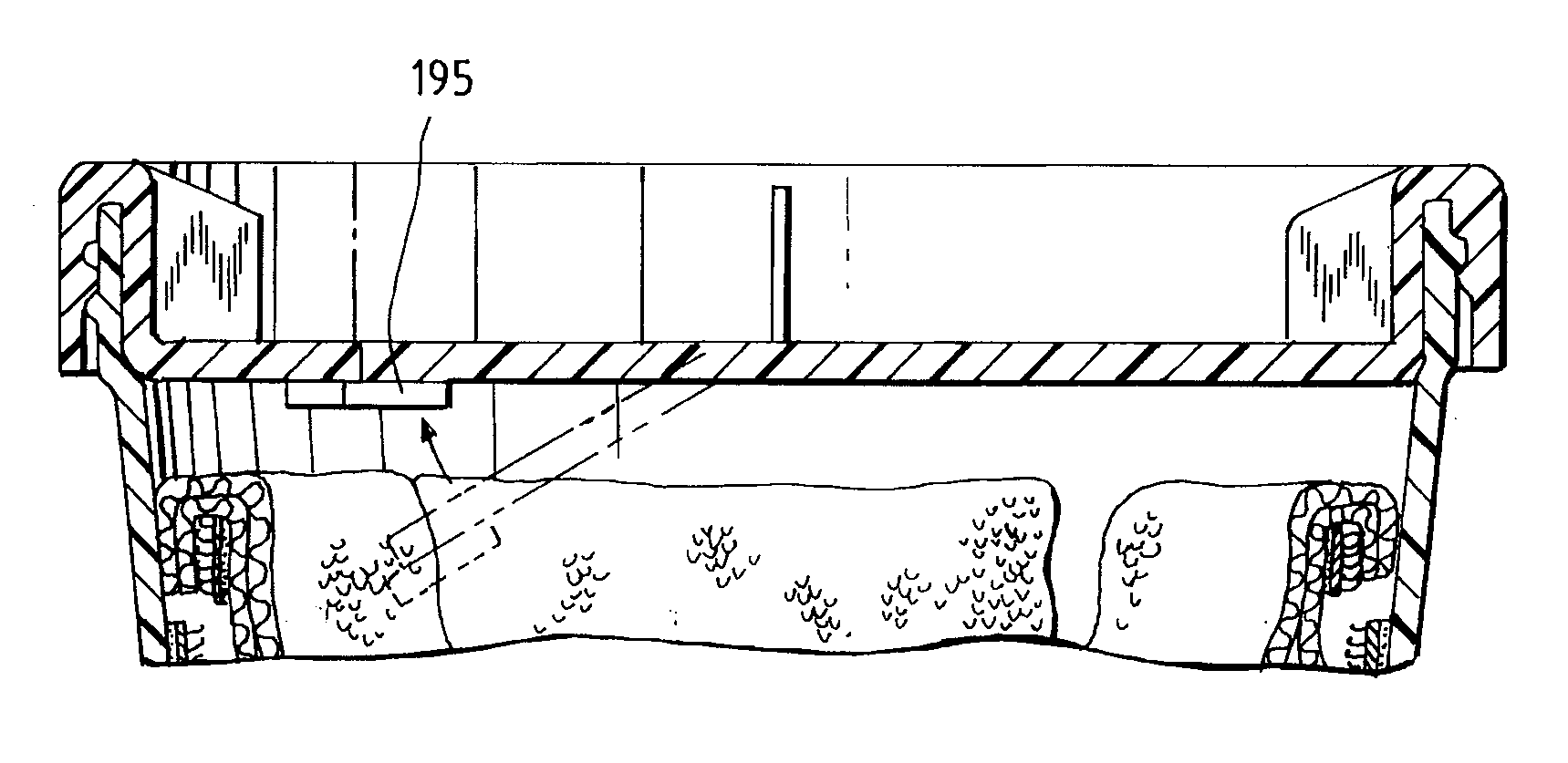

Apparatus and method of disinfecting footwear

InactiveUS20080308748A1Pose health riskDisinfect and sanitize footwearMaterial analysis using wave/particle radiationPhotometryEngineeringMercury vapour

A footwear sterilization and disinfection apparatus and method using UV-C light to sterilize or disinfect the inside of the footwear is provided. The source of the UV-C light may be a singular or a plurality of sources and may include a solid state source, mercury vapour bulb or one or more light emitting diodes. The apparatus for sterilizing and disinfecting footwear may either be a separate device which may be positioned within the footwear or can be provided as part of the footwear during construction regarding manufacture of the footwear. For safety purposes, a sealed housing or shrouding curtain may be provided so that the radiation of UV-C light takes place within the sealed housing or behind the shrouding curtain so that a user is protected from radiation by UV-C light.

Owner:BURROWS CHRISTO NICO WILLIAM

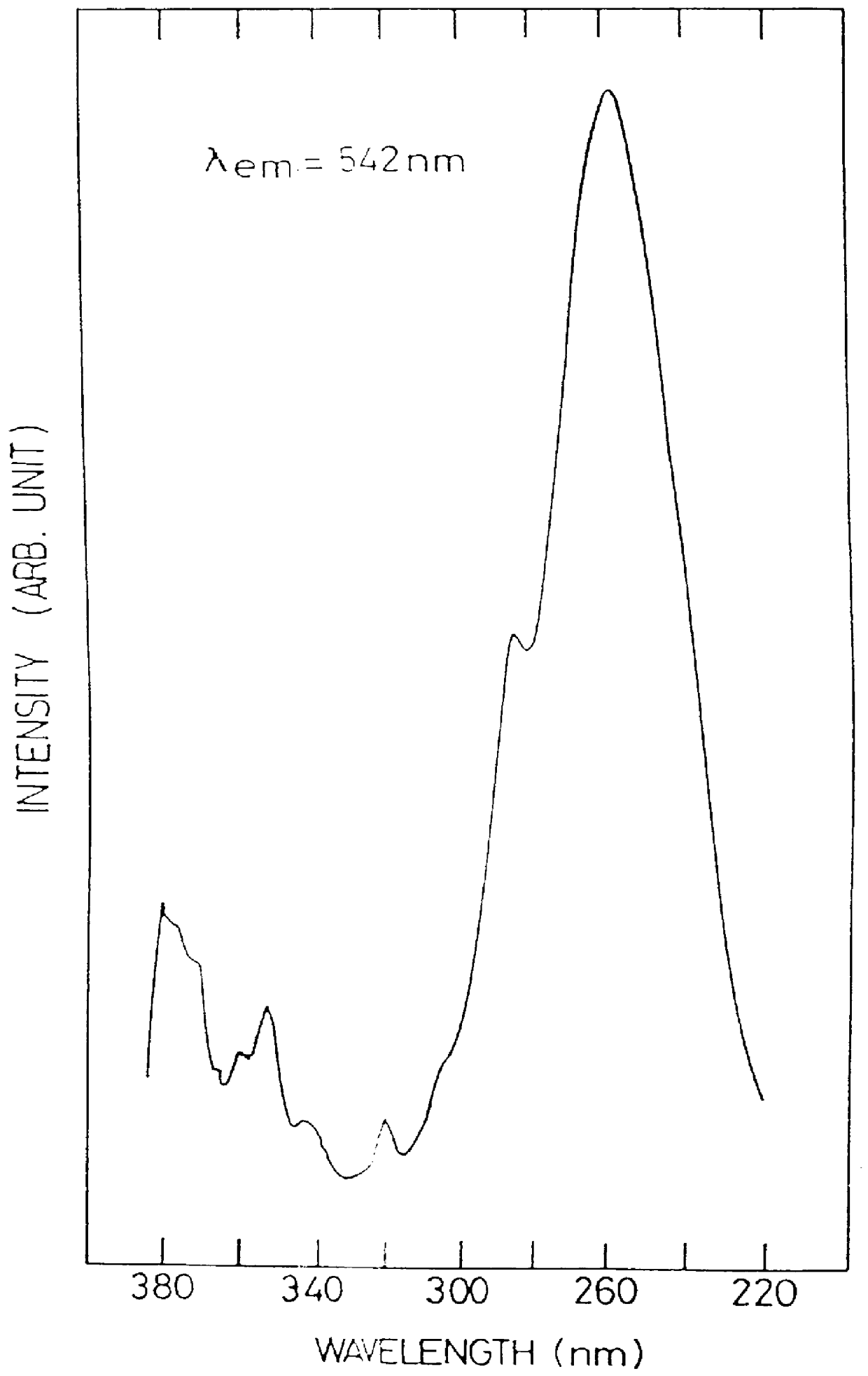

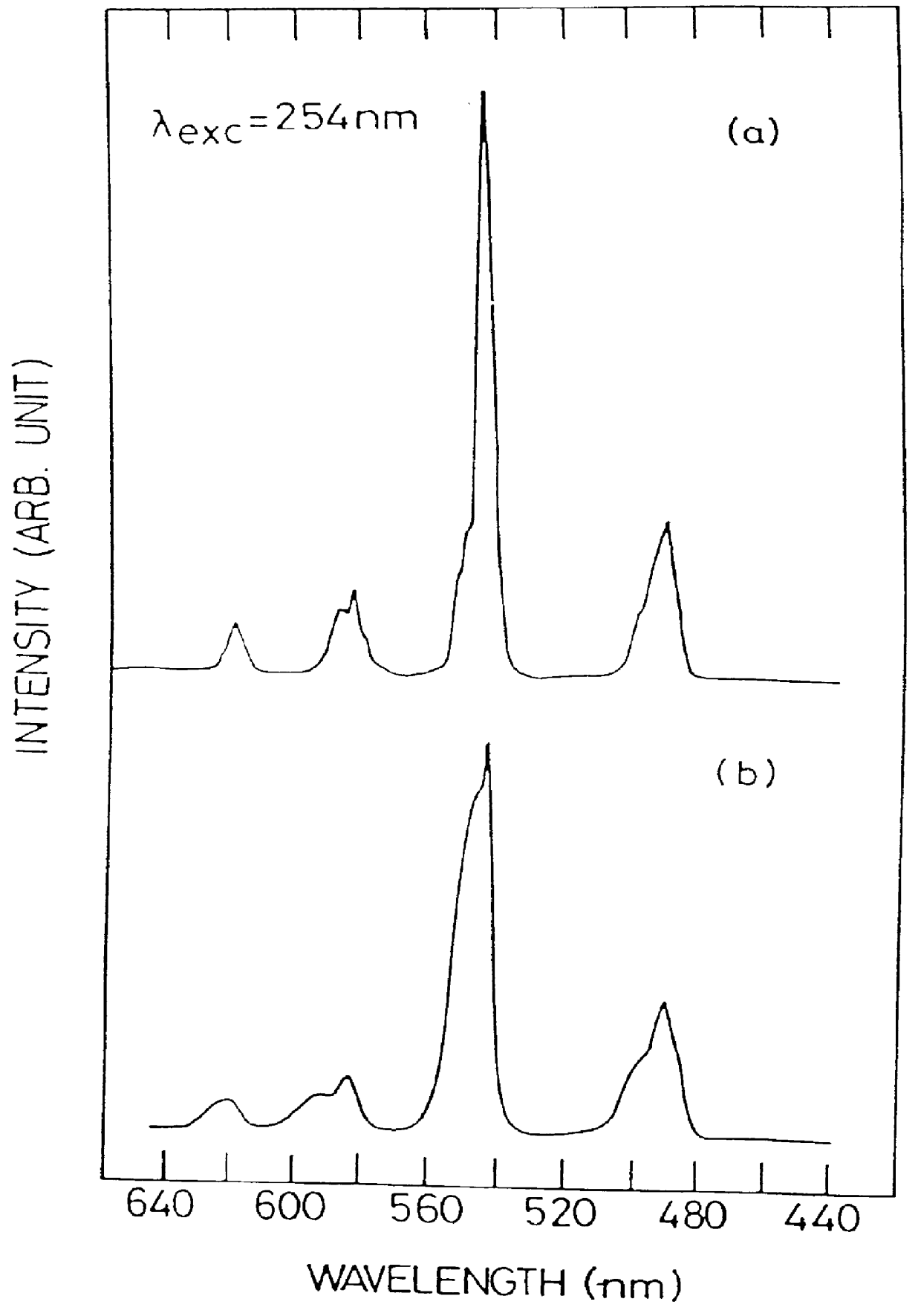

Green emitting TB3+ activated borate phosphors used in low pressure mercury vapour lamps and a process for synthesizing the same

Owner:COUNCIL OF SCI & IND RES

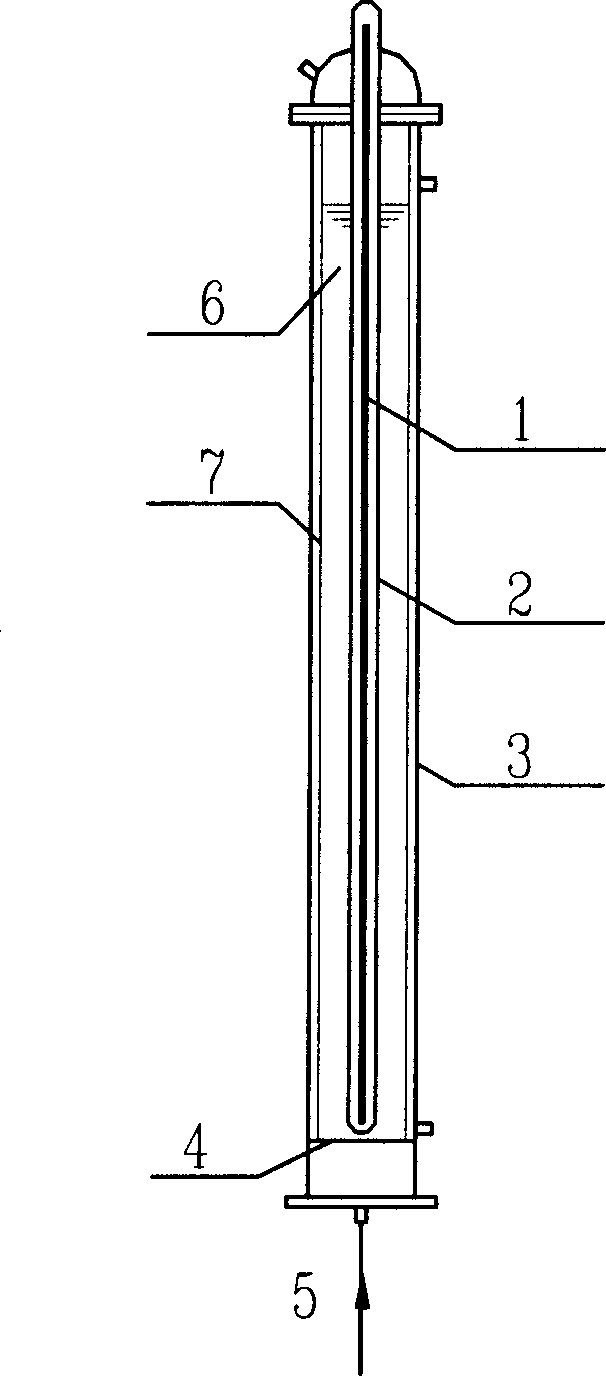

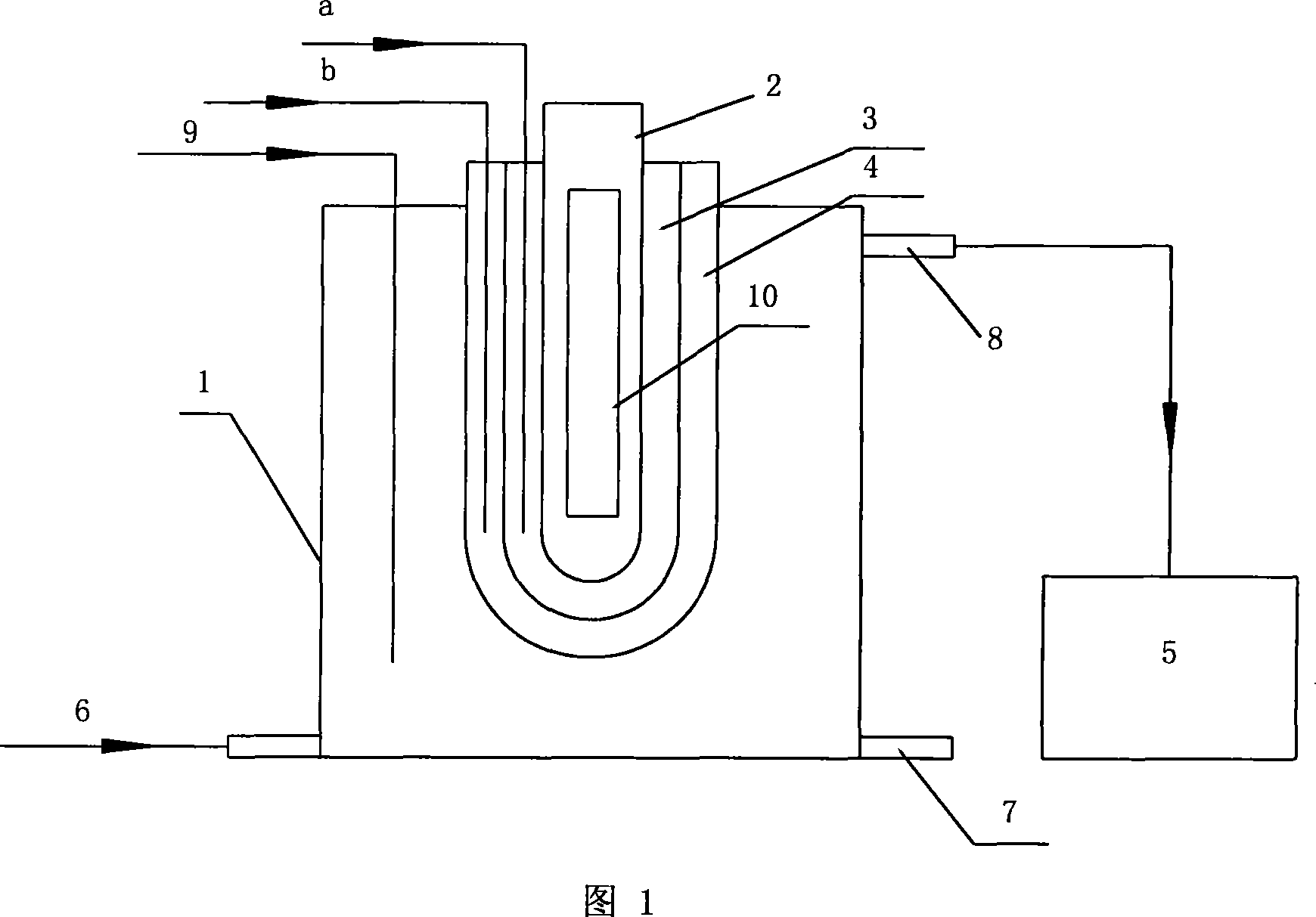

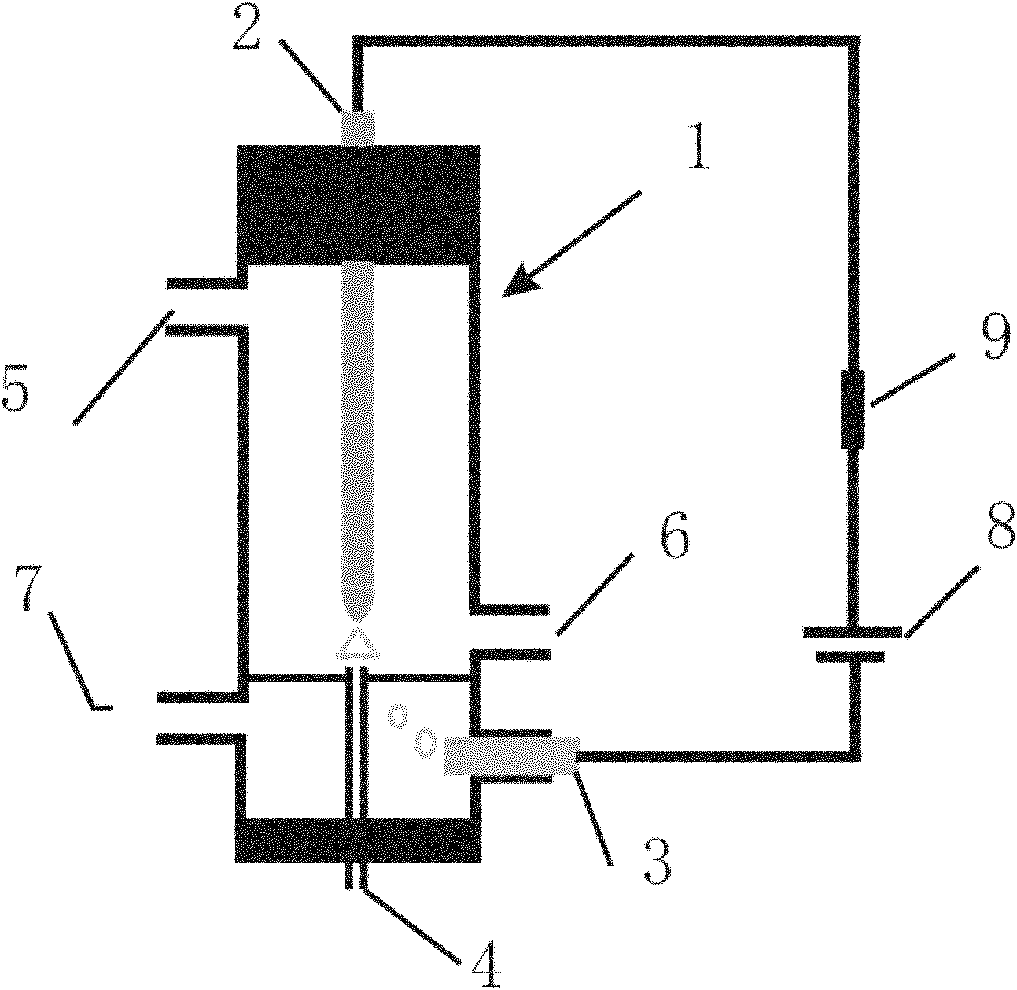

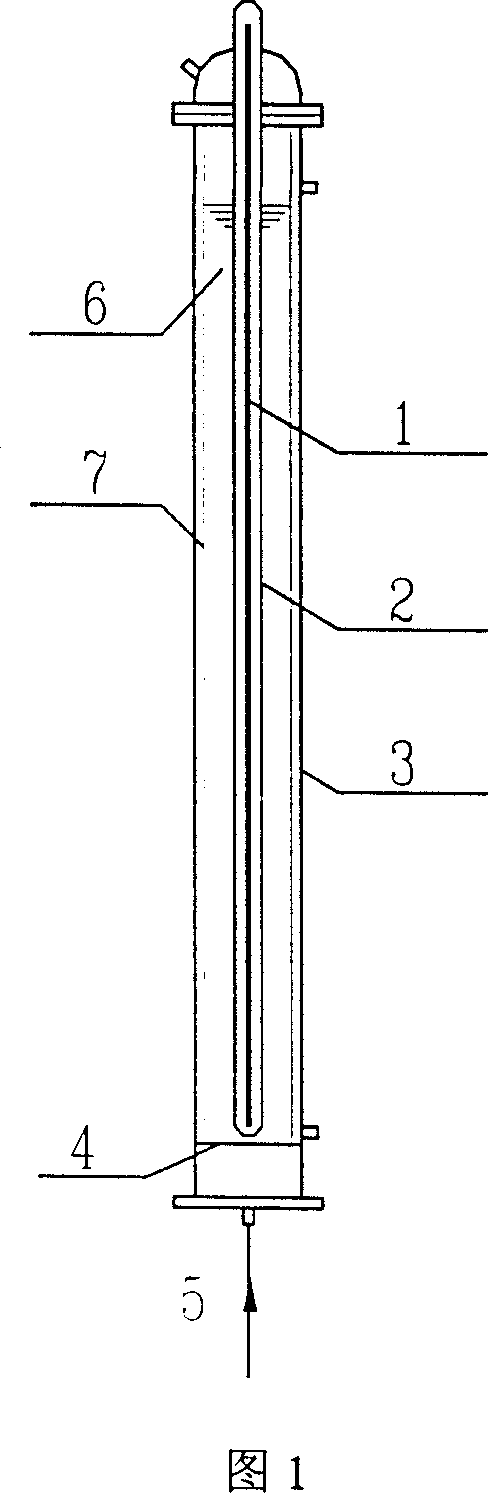

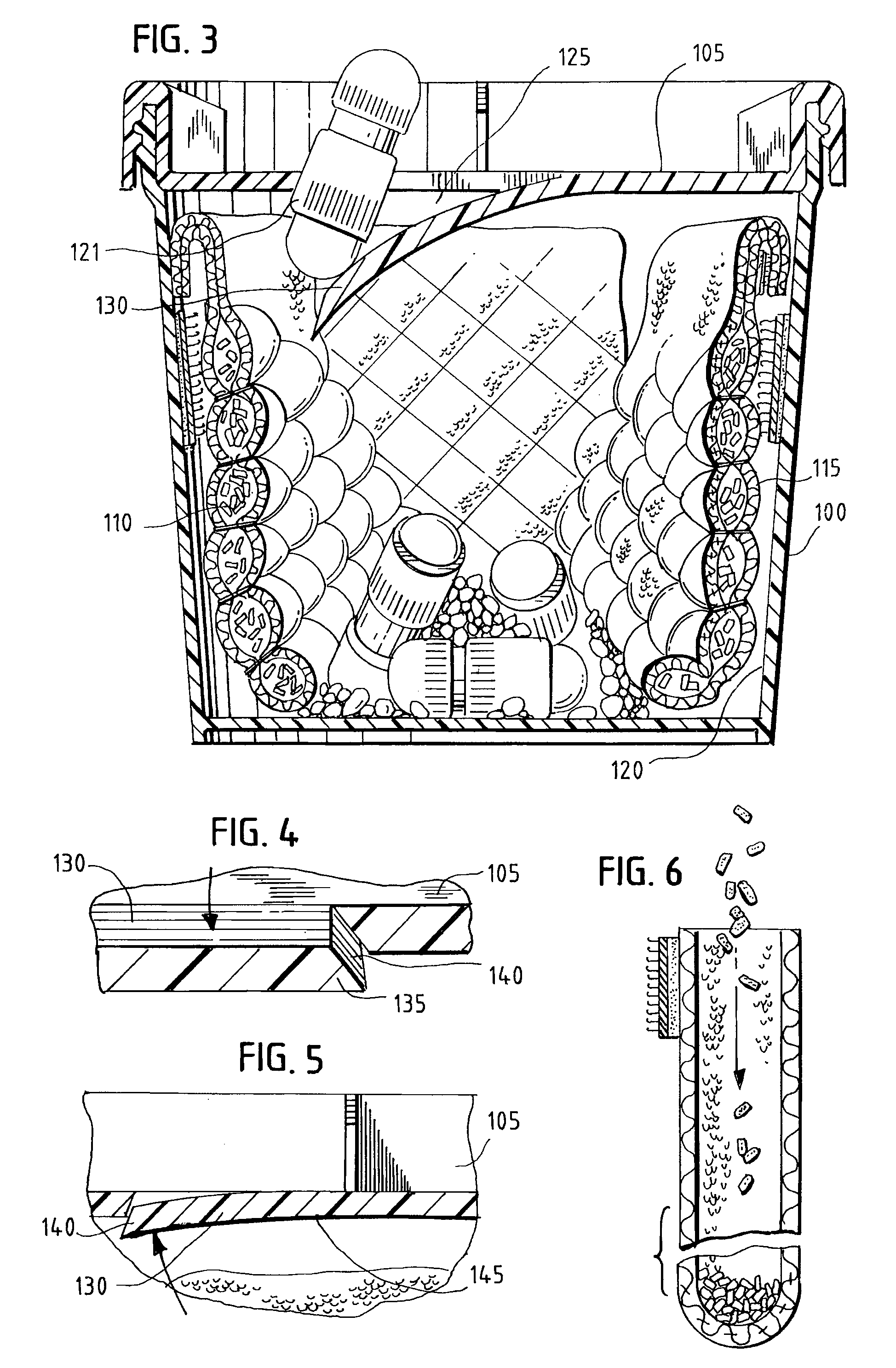

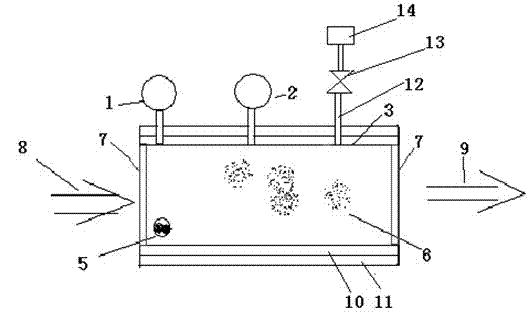

Actinic chemistry reaction device and method for synthesizing provitamin D3

ActiveCN101085755AReduce yieldGood bubblingOrganic chemistryEnergy based chemical/physical/physico-chemical processesNitrogen gasBottle

The invention discloses a photochemical reaction device and a method for synthesizing vitamin D3 by using narrowed high-voltage mercury lamp wavelength and one- step optical isomerism, relating to a vitamin D3. It comprises container, internal pipe, mercury vapour lamp, mediolateral jacket and collecting bottle, the mercury vapour lamp is installed in internal pipe, external jacket is set inside of internal pipe, internal jacket is installed outside of internal pipe, internal jacket is installed between internal tubular lamp and external jacket, the irradiation liquid export of container is connected with collecting bottle. Said method comprises following steps: preparing 7- desmesterol solution and dissloving it in ethanol; evacuating and ventilating nitrogen gas, preparing solution with sodium tungstate or acetate of lead, feeding it into external jacket as filtering liquid, preparing solution with cobalt sulfate, nickel sulfate, sulphuric acid and water, feeding it into internal jacket as filtering liquid, feeding 7- desmesterol solution from feed inlet through condenser circulation for photochemical reaction, ventilating nitrogen gas from feed inlet to mix with 7- desmesterol solution, discharging solution after photochemical process into collecting bottle.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

Method for removing acid gas from waste gas

The invention relates to a method for removing an acid gas from a waste gas. In the method, sulfur oxide, nitric oxide or mercury vapour as the acid gas is removed before the waste gas is discharged into the atmosphere by enabling the waste gas to be in contact with a composition containing organic sulfoxide.

Owner:LEXTRAN

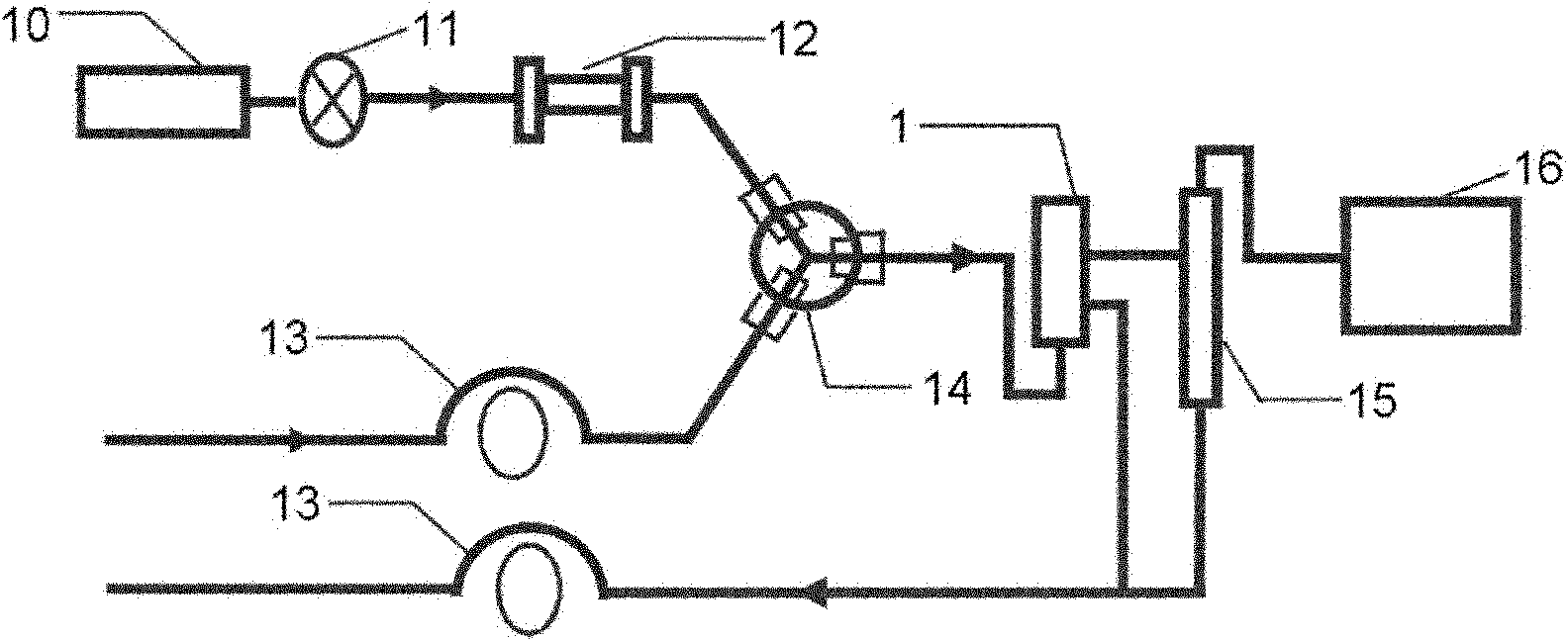

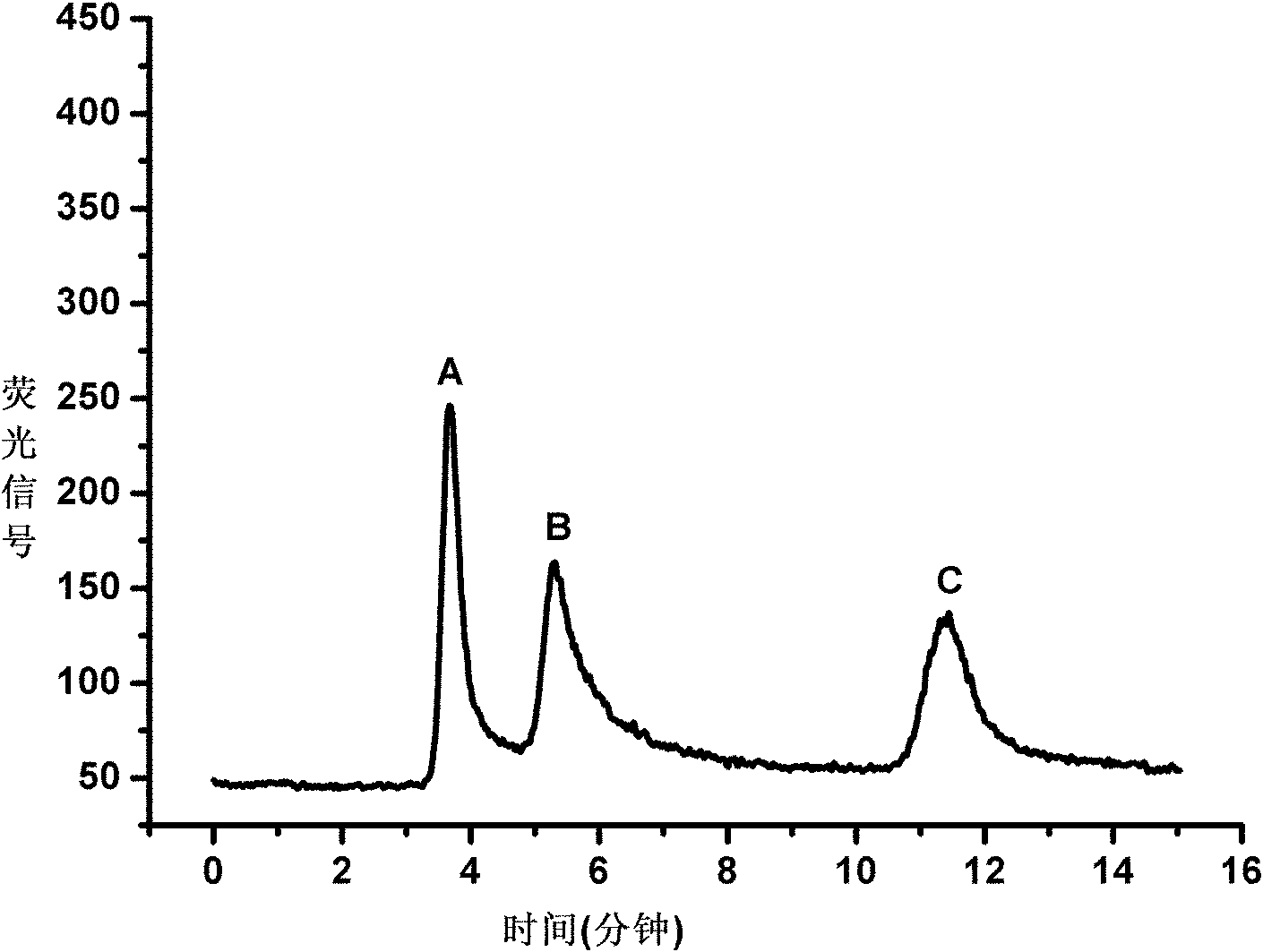

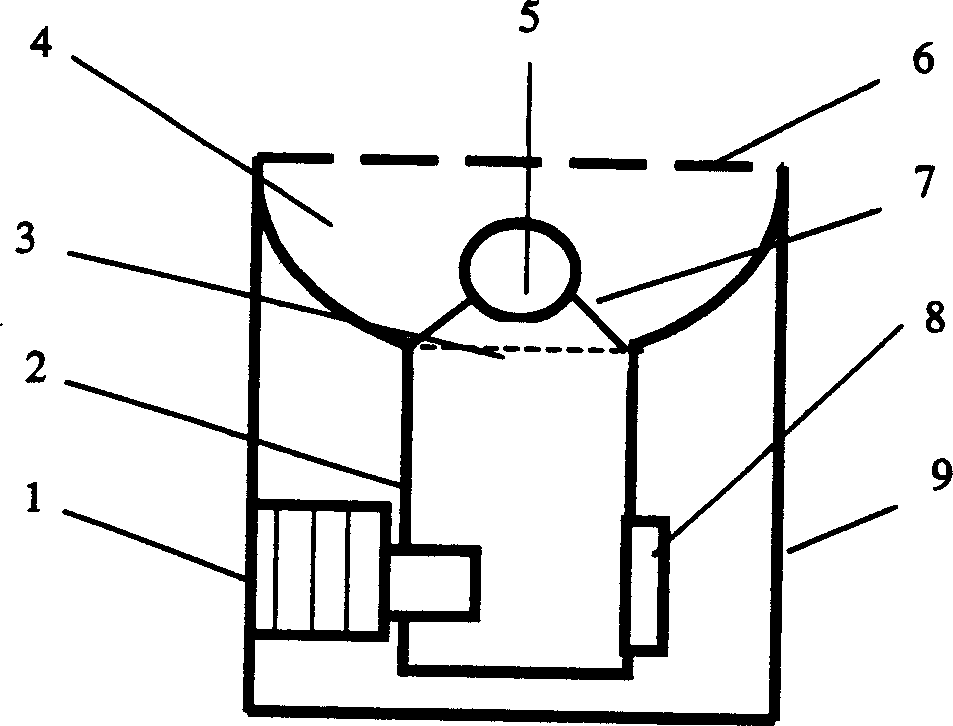

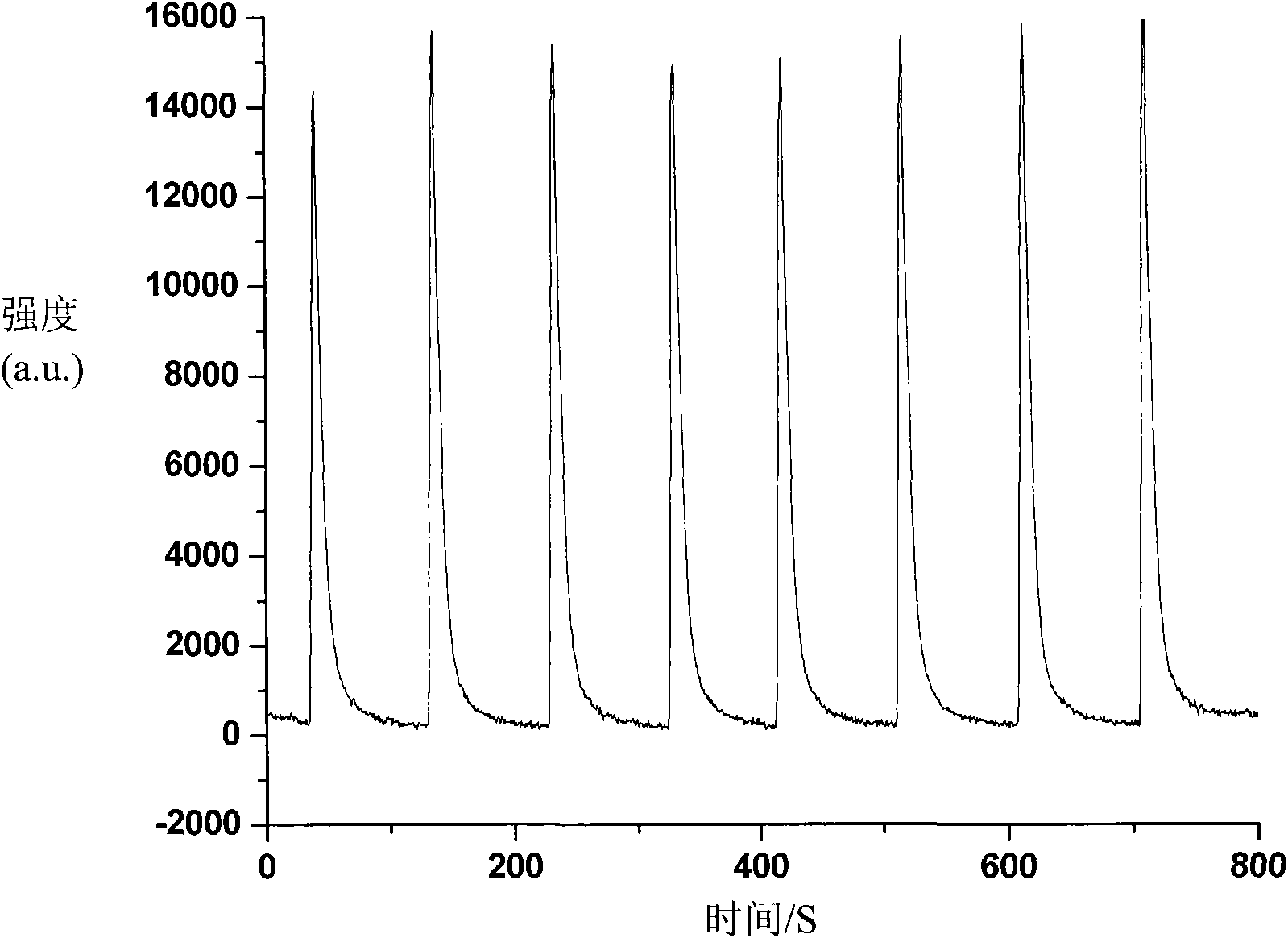

Mercury morphological analysis method based on liquid cathode discharge and mercury vapor generating device

InactiveCN102033103AAchieve steamEfficient separationComponent separationAnalysis by electrical excitationFluorescenceINTRODUCTION device

The invention discloses a mercury morphological analysis method based on liquid cathode discharge and a mercury vapor generating device. The method comprises: a mercury-containing sample solution is introduced into a chromatographic column of a liquid chromatograph; a discharge medium carrier flow passes through a sample introduction device and is introduced into a sample introduction capillary tube of a discharge pool with the effluence of the chromatographic column through a tee joint; by taking a metal electrode as an anode, and graphite, platinum or a stainless steel material as a cathode, liquid cathode discharging is carried out to generate vapor which is carried by a carrier gas into a gas-liquid separator; and finally the separated gas is detected by an atomic fluorescence spectrometer to obtain the morphology of mercury. Through the method provided by the invention, organic mercury and inorganic mercury in an object to be detected are effectively separated and detected; and the method has the advantages of small volume, low energy consumption, high mercury vapor generation efficiency and low matrix interference, is simple in operation and can be used for analyzing the morphology of mercury in a biological sample.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method and apparatus for NOx and Hg removal

InactiveUS20080044333A1Prevent buildupStabilizing iron EDTANitrogen compoundsDispersed particle separationCyclic processMercury vapour

A cyclic process for the removal of NOx from a NOx containing feed gas, and optionally removal mercury vapour and / or sulfur dioxide is provided. A process is also provided by which an iron chelate absorbent may be thermally regenerated.

Owner:HAKKA LEO E +3

Microwave ultra violet light source

InactiveCN1549300ANo electrode degradationNo electrode lossElectric discharge lampsEtchingUltraviolet

The present invention discloses a microwave UV light source. It is composed of magnetron, microwave waveguide, microwave energy-feeding hole, microwave resonant cavity, UV lamp, microwave screening net, lamp stand, fan and base. It is characterized by that after the UV lamp is evacuated, its interior can be filled with inert gas, mercury vapour or metal halide vapour and mixture of the above-mentioned gases. Said light source can be used for implementing disinfection and sterilization of gas, liquid and solid, photochemical synthesis of chemical substance and UV etching and UV information erasion of electronic material and device.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Method for recovering mercury from multi-element mercury-containing hazardous solid wastes by high-temperature rotary roasting

The invention discloses a method for recovering mercury from multi-element mercury-containing hazardous solid wastes by high-temperature rotary roasting, and belongs to the field of environmental protection and metallurgy. The method comprises the following steps: crushing multi-element mercury-containing solid wastes namely nonferrous metallurgy slag, flue dust and waste catalysts until the granularity is 130-150 microns; adding quicklime accounting for 20-40% of the total weight of the mercury-containing solid wastes, and stirring continuously at 70-90 DEG C for 2 hours to ensure that mercury compounds are converted into mercury oxide; roasting in a high-temperature rotary furnace at a roasting temperature of 75-850 DEG C for 2-8 hours to ensure that mercury oxide is decomposed into mercury vapor; performing cyclone dust collection, and then performing bag dust collection to remove dust from the mercury vapor; performing two-stage condensation recovery on the mercury vapor by adopting tubular condensing equipment, and condensing and collecting the mercury vapor in a mercury collecting tank; and recovering mercury-containing tail gas by adopting a filler adsorption tower. By adopting the method disclosed by the invention, the problems of difficult stacking of the multi-element mercury-containing solid wastes, environmental pollution and mercury recovery are solved, and the economic value of mercury is improved.

Owner:贵州重力科技环保股份有限公司

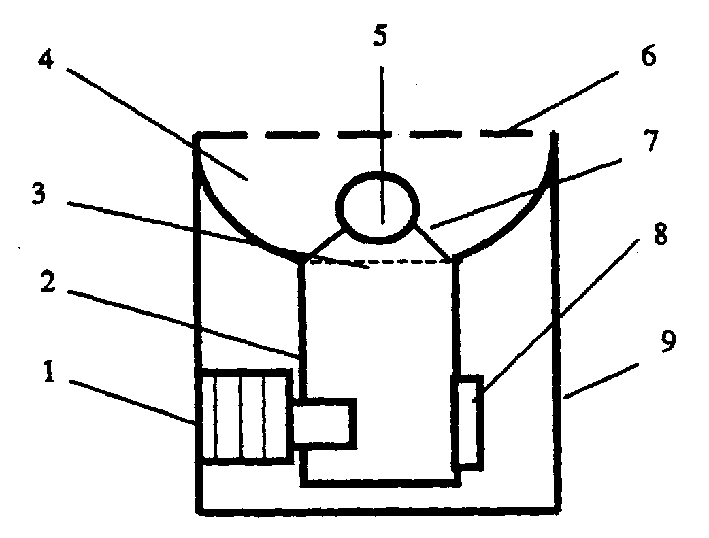

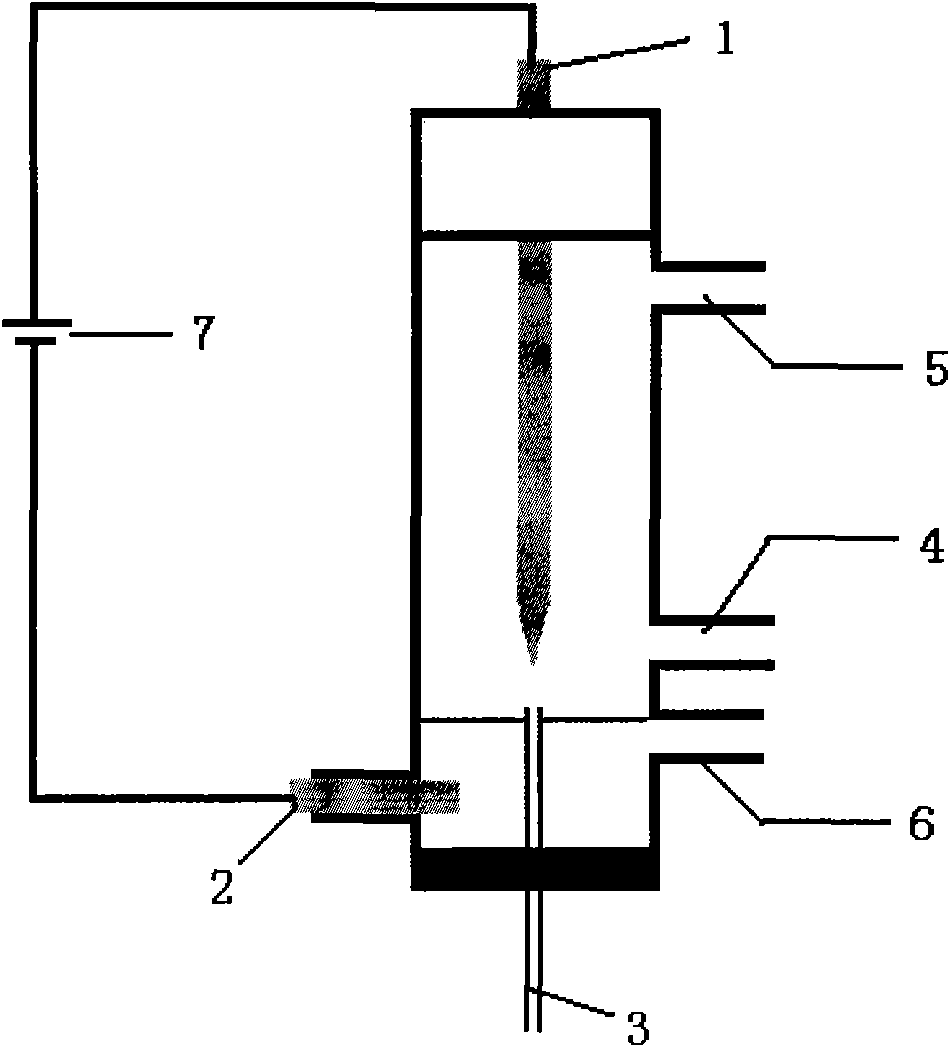

Mercury vapour generation method and device

InactiveCN101556246AReduce lossReduce riskAnalysis by electrical excitationMaterial analysis by electric/magnetic meansElectricityMercury vapour

The invention discloses a mercury vapour generation method and a device; the method realizes the generation of mercury in liquid sample in vapour form by the discharge of liquid cathode, comprising the following steps: first putting an anode and a cathode connected with two electrodes of a direct current power supply in a sealed discharging device, leading electrolyte solution of the sample containing mercury in the discharging device by a capillary, generating the discharging between the anode and the liquid sample on the sharp end of the capillary so as to generate the mercury vapour. The invention also provides a mercury vapour generation device, comprising the anode and the cathode connected with the two electrodes of the direct current power supply, wherein the anode and the cathode are placed in the discharging device; the discharging device is provided with the capillary with inner diameter of 01-5mm; the sample containing mercury is led in the discharging device by the capillary; the distance between the opening of the capillary and the anode is 1-4mm. The invention realizes the vapour generation of mercury by discharging without any reducing agent so as to reduce the reagent wastage and pollution danger.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for defluorinating and degrading complete fluorine substituted compounds

InactiveCN100347137CLow toxicityEasy to handleSolid waste disposalOrganic decompositionUltravioletPerfluorooctanyl sulfonate

A defluorinating and degrading method of fluorine substituted compound is characterized by vacuum ultraviolet irradiating PFOS and PFOA etc. fluorine substituted compound at anaerobic condition, defluorinating reacting fluorine substituted compound at irradiation of 185nm ultraviolet mercury vapour light or 172nm xenon quasi molecule laser light, inducing protective inert gas or reducing gas for realizing anaerobic condition, or adding reducing substance or semiconductor catalyst with high conducting band energy level during reacting process to improve defluorinating and decomposing ratio. It achieves simple operation and non-toxic.

Owner:TSINGHUA UNIV

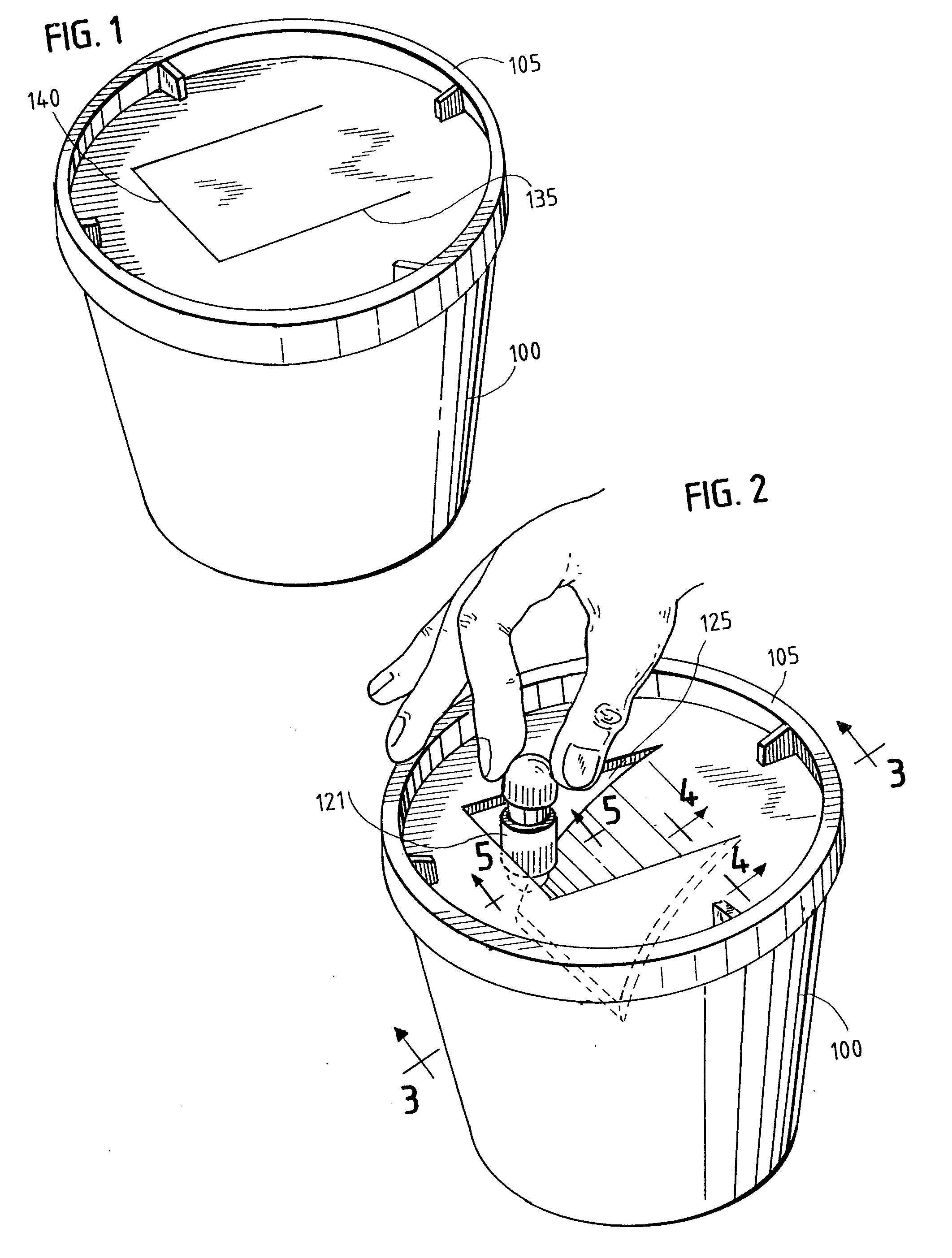

Recycling container for the collection and temporary storage of mercury contaminated wastes in dental facilities

InactiveUS20080257759A1Prevents and reduce releaseReduce releaseDiagnosticsSurgeryWaste treatmentEngineering

The present invention is directed to a container for the collection and temporary storage of amalgams and other mercury wastes. The container can include a hollow body with air-tight lid, and one or more mercury sorbents contained in a filter bag. The filter bag covers the inside surface of the hollow body and has holes that allow air exchange between the air in the hollow body and the sorbents. As air exchange occurs, mercury vapors released from dental wastes binds to the mercury binding materials. A self-closing door was made on the lid, which automatically closes after each waste disposal.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

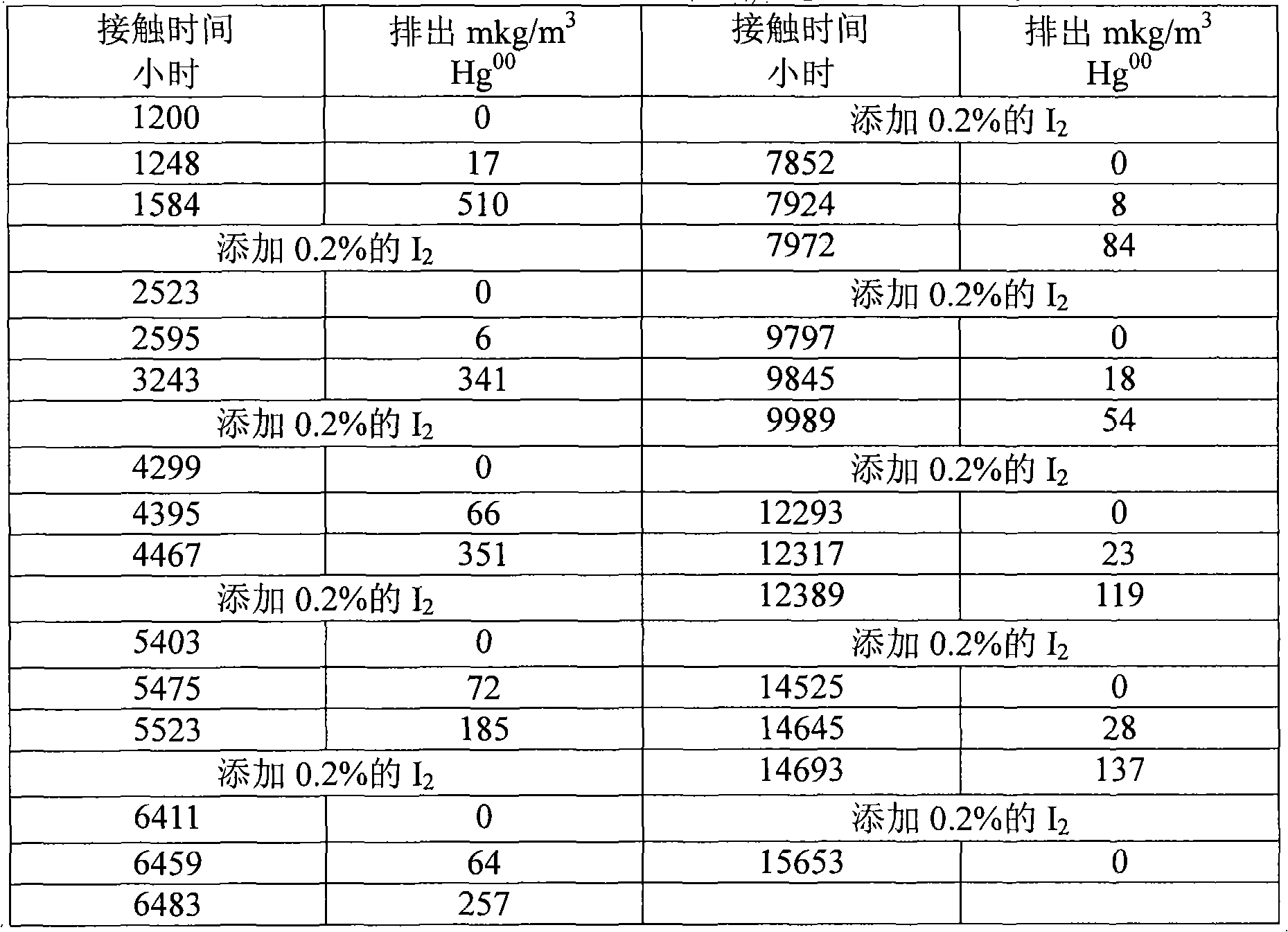

Method and apparatus for producing mercury vapor with standard concentration

InactiveCN102253168ANo pollution in the processSimple structurePreparing sample for investigationTemperature controlPhysical chemistry

The invention discloses a method and an apparatus for producing mercury vapor with a standard concentration. The method comprises steps that a sample cell is vacuumized, added with liquid mercury or amalgam, and sealed; the sample cell is heated or cooled; a mercury vapor pressure in the sample cell is changed with the temperature, and pressure and temperature of the mercury vapor are detected by a pressure gauge; a mercury saturated vapor pressure is obtained from a mercury vapor saturated pressure and temperature parallel table according to the detected pressure and temperature; then a mercury saturated vapor concentration is obtained by calculating according to a formula; and mercury vapor with a standard concentration is obtained. A mercury vapor generator for calibration comprises a pressure gauge, a thermometer, a sample cell, refrigeration and heating equipment, liquid mercury or amalgam, and transparent quartz window. The invention has beneficial effects that the mercury vapor concentration is controlled by adjusting temperature, and the liquid mercury and the amalgam are all sealed in the sample cell, so as to avoid discharge to generate environment pollution, and simplify a structure of a current mercury vapor generator for environment monitoring calibration and an exhaust-gas treatment system.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

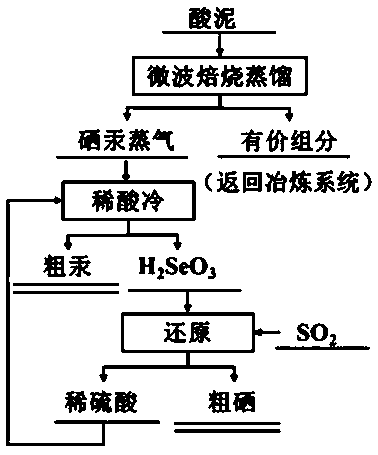

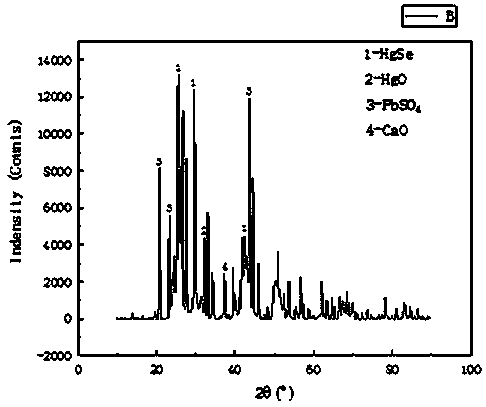

Method for microwave low-temperature treatment of acid mud and synchronous recovery of selenium and mercury

ActiveCN111057852AAchieve separationIncrease dielectric lossProcess efficiency improvementElemental selenium/telluriumPhysical chemistryHeat conservation

Owner:KUNMING UNIV OF SCI & TECH

Amalgam balls having an alloy coating

ActiveUS20140055026A1High measurement accuracyIncrease contentLiquid surface applicatorsDischarge tube luminescnet screensGas-discharge lampAlloy coating

Energy-saving lamps contain a gas filling of mercury vapour and argon in a gas discharge bulb. Amalgam balls are used for filling the gas discharge bulb with mercury. Novel coated balls whose operating life in the case of automatic metered introduction is increased by coating of the balls with an alloy powder and conglutination of the amalgam balls during storage and processing is prevented are proposed.

Owner:UMICORE AG & CO KG

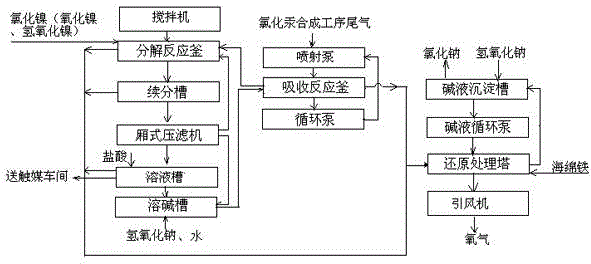

Processing method of chlorine-containing tail gas produced by mercuric chloride production

ActiveCN104084026APromote decompositionGood catalyticDispersed particle separationMercury halidesChlorine dioxideReduction treatment

The invention discloses a processing method of chlorine-containing tail gas produced by mercuric chloride production. The processing method comprises the following steps: producing a sodium hypochlorite solution from tail gas which contains chlorine and mercuric chloride vapor, and then adding nickel chloride (or nickel oxide or nickel hydroxide) for nickel oxide hydroxide generating reaction; mixing sodium hypochlorite with nickel oxide hydroxide in a decomposition reaction kettle for two to three hours; performing coexistence of a solution from the decomposition reaction kettle with nickel oxide hydroxide in a continuous decomposition tank for three to five days, wherein when the pH value approaches to seven to eight, decomposition is completed; then putting a sodium chloride solution into a soluble alkali trough, adding alkali until the concentration of sodium hydroxide reaches 5% to 10%, and then returning to an absorption reaction kettle to be used again; sucking chlorine dioxide, chlorine and hydrochloric acid gas which are decomposed everywhere into a reduction treatment tower by negative pressure generated by a fan to enable the gases to contact with alkali liquor, wherein sodium chloride returns to an alkali liquor precipitation tank, and gases are exhausted by an induced draft fan. With the processing method, stable by-products can be obtained, highly toxic mercury chloride can be recycled, and the up-to-standard release of tail gas can be realized.

Owner:贵州重力科技环保股份有限公司

Waste gas treatment process including removal of mercury

A process for removing contaminants from a waste gas stream comprises treating the waste gas stream to remove at least one of SO2 and NOx and to obtain a lean stream having a reduced level of at least one of SO2 and NOx and, contacting the lean gas stream with a mercury absorbent solution comprising permanganate to remove mercury vapour and to obtain a mercury lean stream and a mercury rich absorbent solution. The mercury rich absorbent solution may be subsequently treated on a batch basis to remove precipitated manganese dioxide and obtain a solution containing mercury ions.

Owner:CANSOLV TECH INC

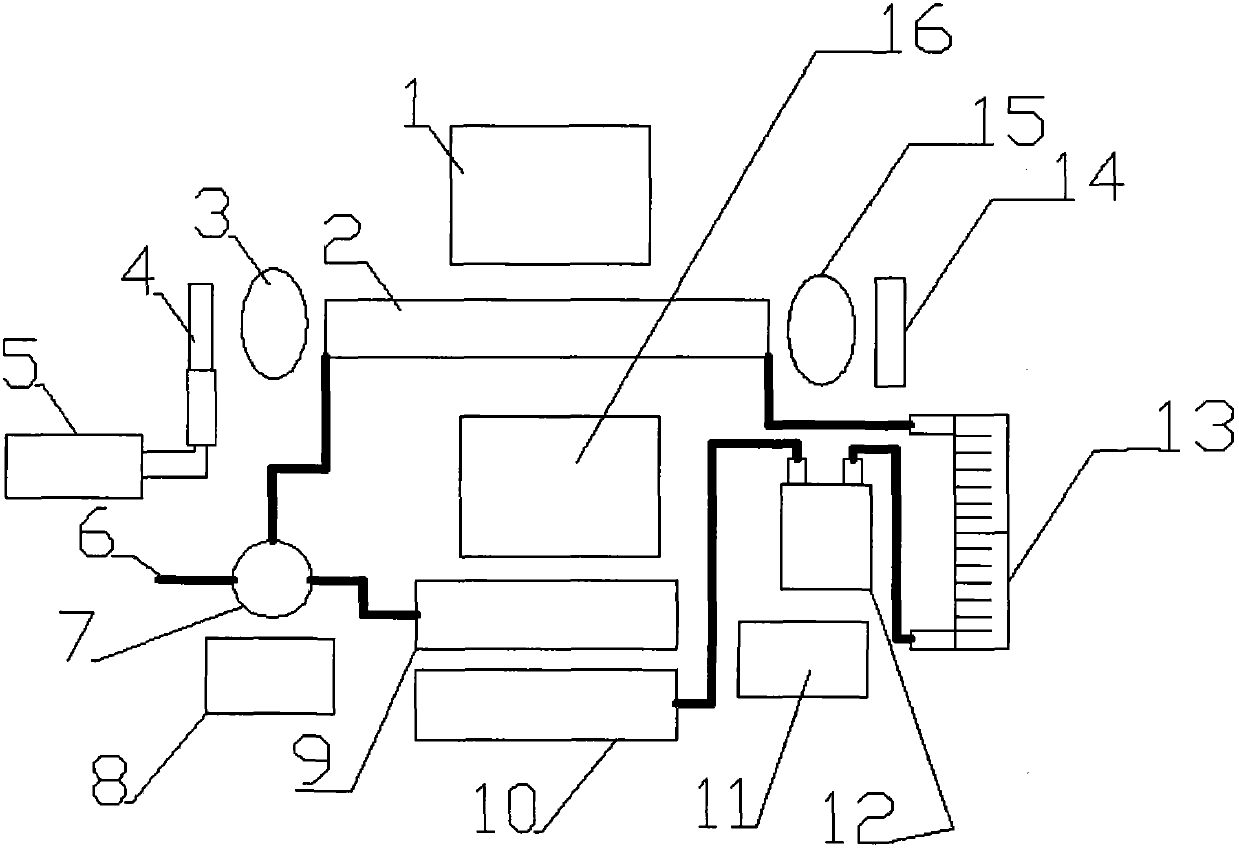

Smoke mercury online monitoring instrument

InactiveCN102998268AReduce pollutionEffective absorptionColor/spectral properties measurementsData displayControl system

The invention relates to a smoke mercury online monitoring instrument, and belongs to the technical field of environment monitoring. The instrument is composed of a touch screen display system, a CPU (central processing unit) control system, a detection system, a sampling system and an absorption tower, wherein the touch screen display system finishes data display, data calculation and communication with the CPU control system; the CPU control system carries out a series of actions of sampling, air pumping and AD collection and the like; the detection system finishes absorption detection of mercury vapor; the sampling system finishes sampling switching of smoke and zero gas, and the absorption tower finishes adsorption of mercury in sample gas. The smoke mercury online monitoring instrument can be used for continuously monitoring the concentration of the mercury in the smoke on line, has the characteristics of high precision, high sensitivity, high efficiency, and the like and is suitable for real-time monitoring of the mercury in various smokes.

Owner:中科天融(北京)科技有限公司

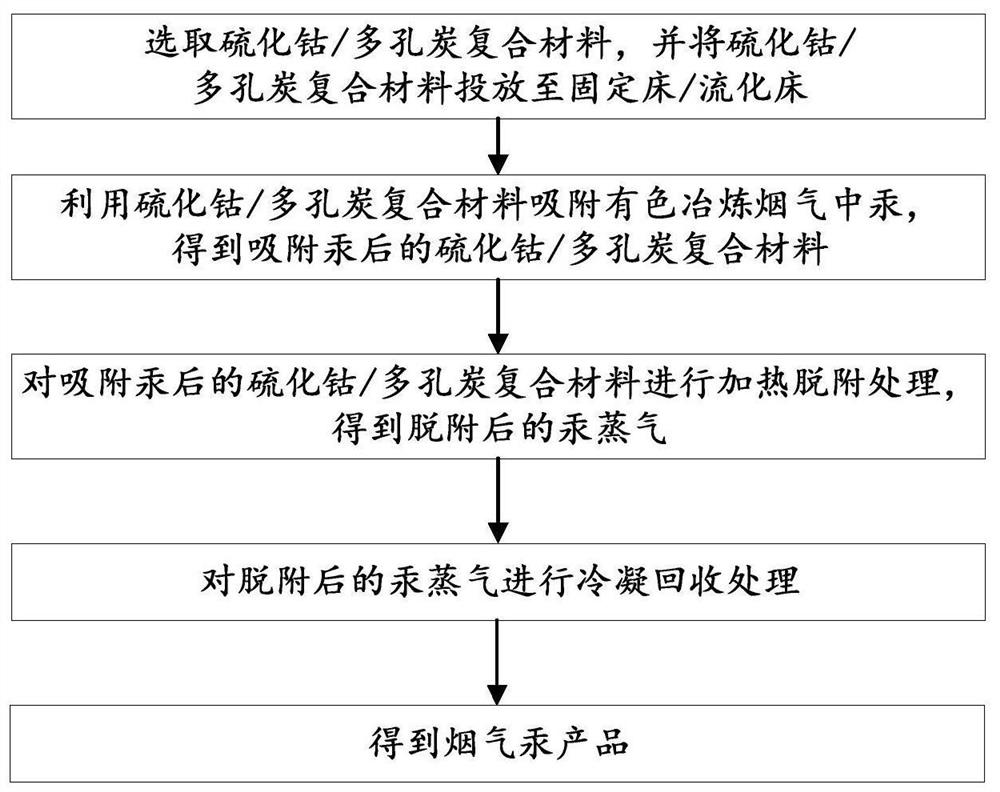

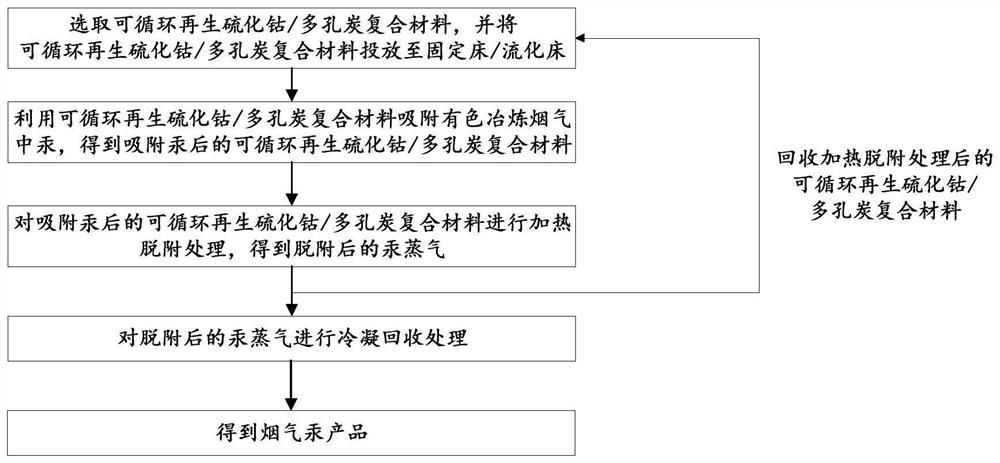

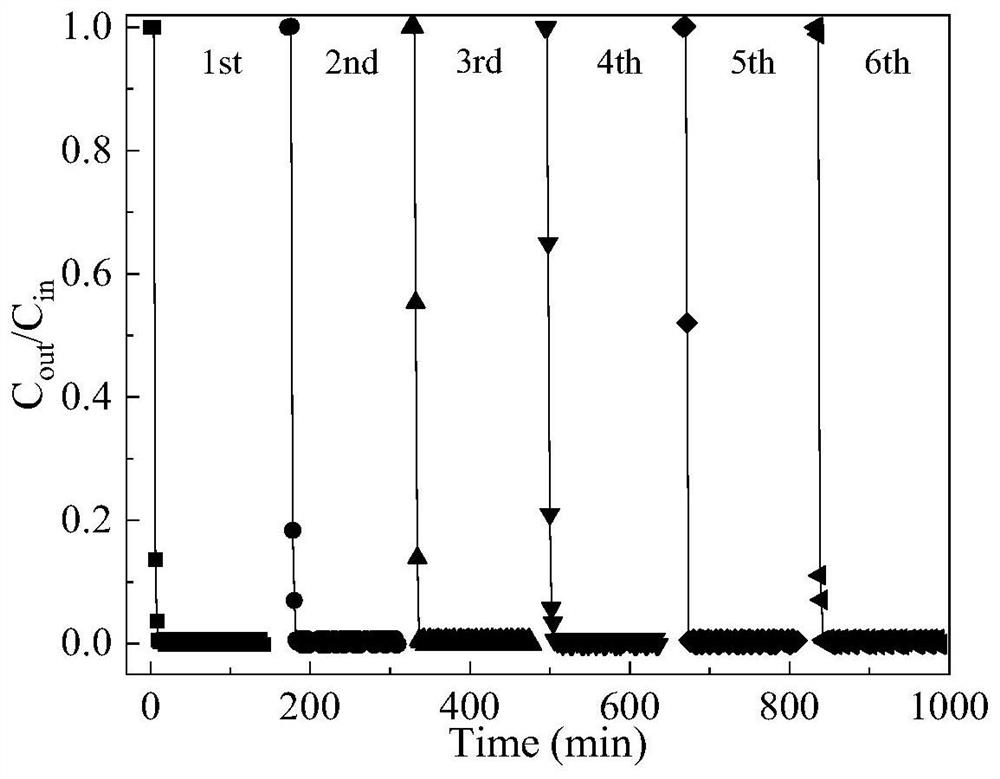

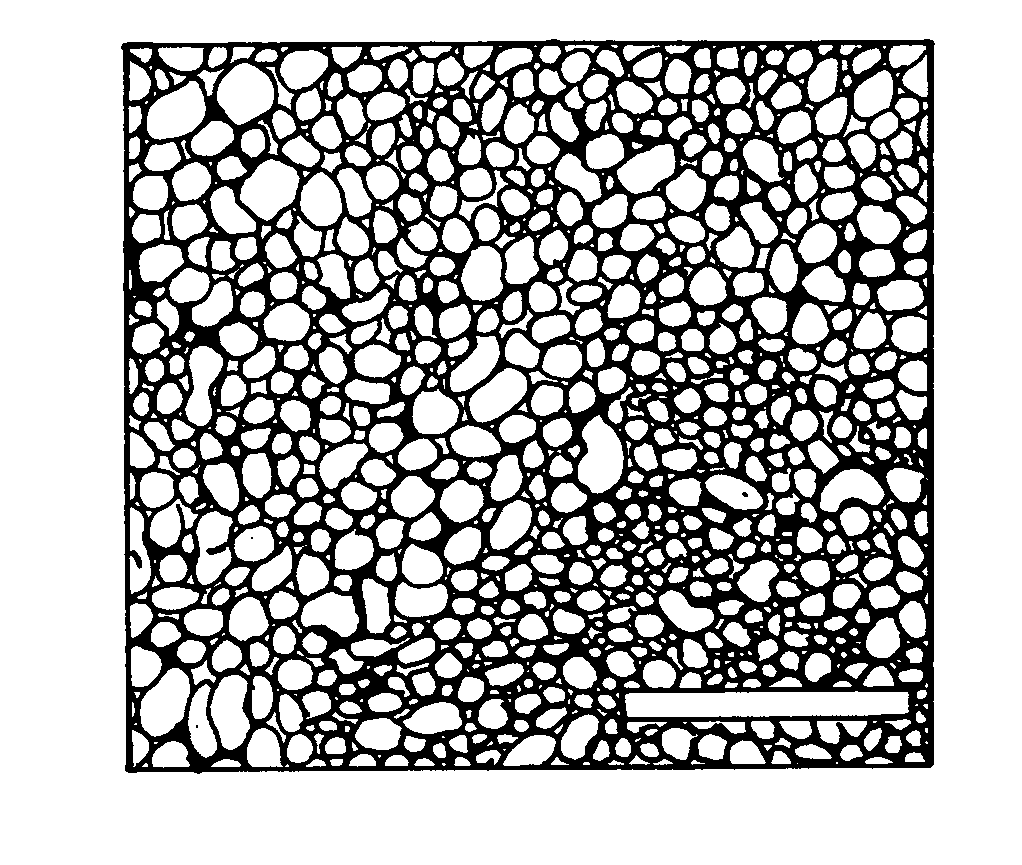

Method for recovering elemental mercury in non-ferrous smelting flue gas

ActiveCN112237822AChemically fixedCompletely break down and releaseGas treatmentOther chemical processesPorous carbonSmelting process

The invention discloses a recovery method of elemental mercury in nonferrous smelting flue gas, and the method comprises the following steps: adsorbing elemental mercury in nonferrous smelting flue gas at the temperature of less than 50 DEG C by using a cobalt sulfide / porous carbon composite material as an adsorbing material, and heating the cobalt sulfide / porous carbon composite material adsorbing elemental mercury to 200 DEG C or above to perform mercury removal treatment, and recycling the volatilized mercury vapor through condensation; wherein the cobalt sulfide / porous carbon composite material subjected to mercury removal treatment can be directly returned to be used for adsorbing elemental mercury in nonferrous smelting flue gas, flue gas mercury generated in the nonferrous smeltingprocess can be effectively recycled, mercury resource waste is avoided, and the economic benefits of nonferrous smelting are increased.

Owner:CENT SOUTH UNIV

Preparation method of absorbent used for removing mercury vapor pollutant

InactiveCN102513056AImprove adsorption capacityStrong ion exchangePhysical/chemical process catalystsOther chemical processesAlcoholSilicic acid

The invention discloses a preparation method of an absorbent used for removing mercury vapor pollutants. The invention belongs to the technical field of chemical engineering. The method comprises steps that: bentonite, cetyl trimethyl ammonium bromide, dodecylamine, polyhexylene alcohol, and tetraethoxysilane are prepared; a bentonite suspension liquid is mixed with cetyl trimethyl ammonium bromide; the mixture is uniformly mixture, dodecylamine and polyhexylene alcohol are added to the mixture, and the obtained mixture is mixed; tetraethoxysilane is added to the mixture, until precipitate is formed; the precipitate is separated and dried, such that powder of the precipitate is obtained; a mixed solution of titanium tetrachloride and dialuminium trichloride is prepared; the prepared powder is soaked in the mixed solution; the mixed solution is stood; excess dilute ammonia water is dropped into the mixed solution, and a reaction is carried out for 12h; the obtained product is subject to drying treatment; the product is annealed, such that the absorbent is prepared. With the method, thermal stability of a system is greatly improved, and the method is environment friendly.

Owner:JIANGSU SIFANG BOILER

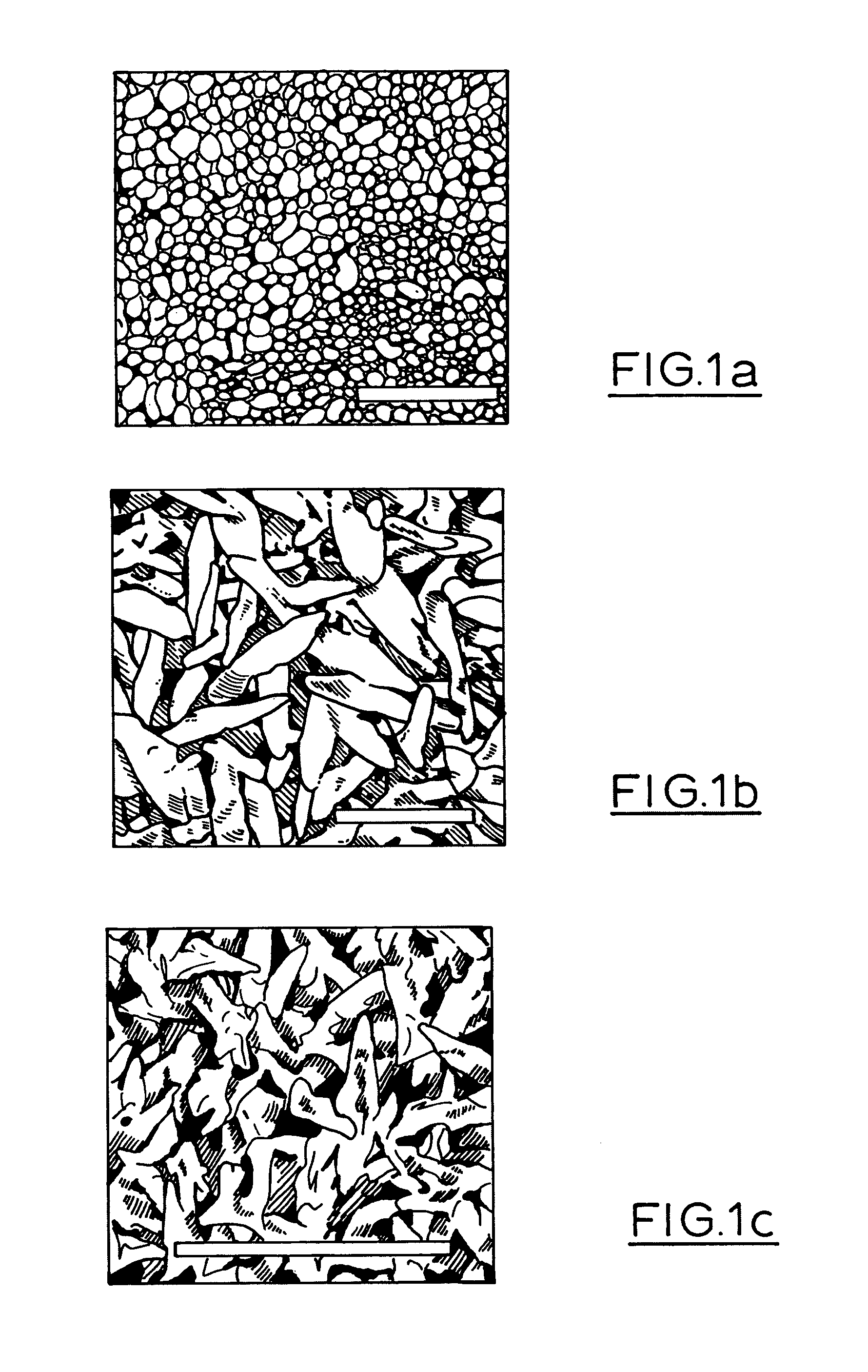

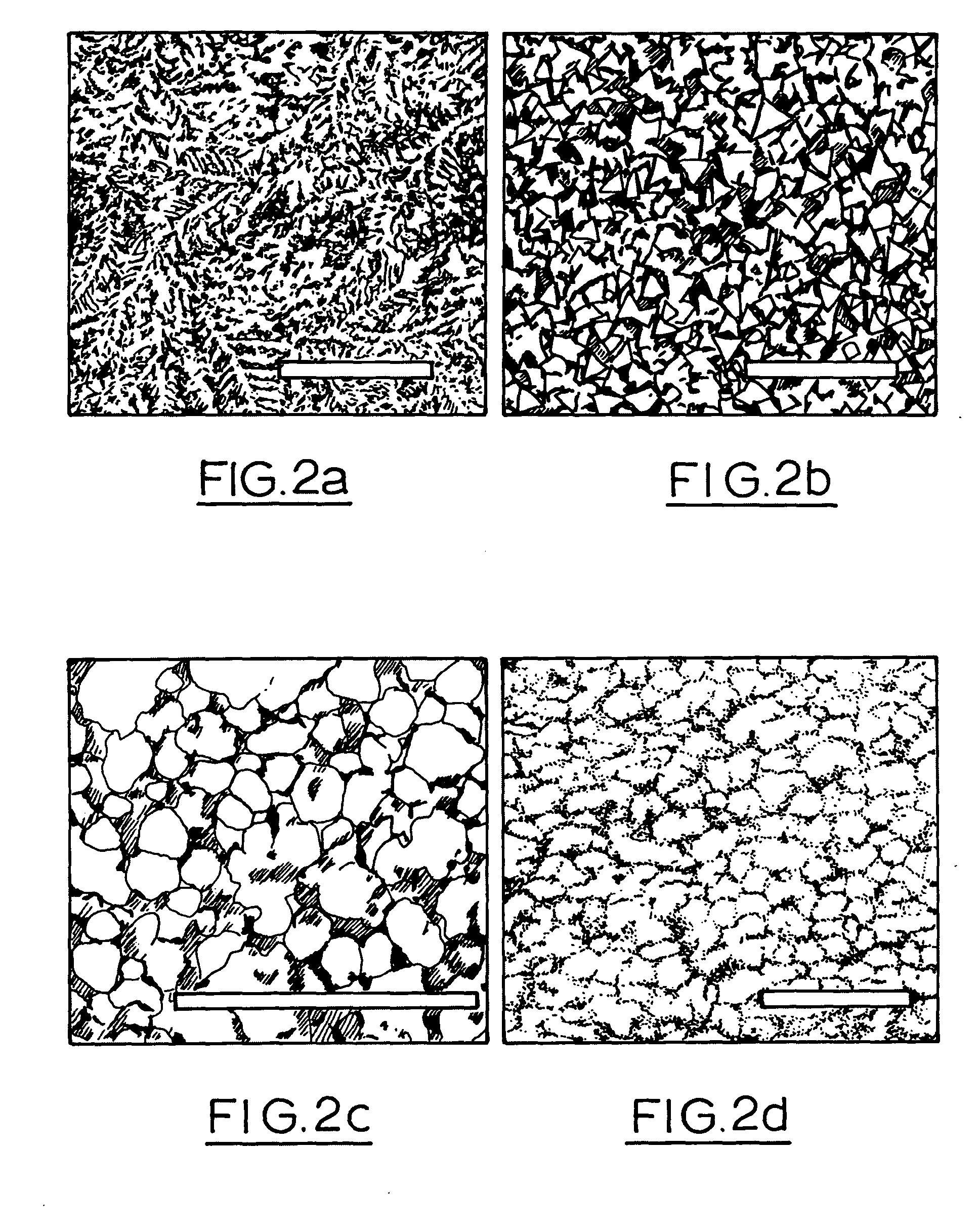

Electrodeposited gold nanostructures

InactiveUS20120073358A1Increase magnitudeImprove performanceTesting metalsThin material handlingNanostructureFacet

A mercury vapour sensor in which the sensor surface is a gold substrate, and gold nanostructures with controlled crystallographic facets are strongly adhered to the substrate. A substantial increase in response magnitude and stability of a quartz crystal microbalance (QCM) based mercury vapour sensor is achieved using this sensor surface. The method of forming gold nanostructures on a gold substrate includes the steps of electrodepositing gold onto a gold working electrode from a solution of hydrogen or alkali metal tetrahaloaureate (III) and an additive such as lead acetate at an electro-deposition temperature between 20 and 40° C. and a deposition time of at least 15 seconds. The growth is controlled by the composition of the deposition solution, the temperature and the current density. The deposition rates may be varied as will the deposition times which are preferably about 150 seconds but may be as long as 15 minutes. The preferred deposition solution contains 2.718 g / l of hydrogen tetrachloroaurate(III) hydrate with 0.1 to 0.5 g / l of lead acetate.

Owner:ROYAL MELBOURNE INST OF TECH

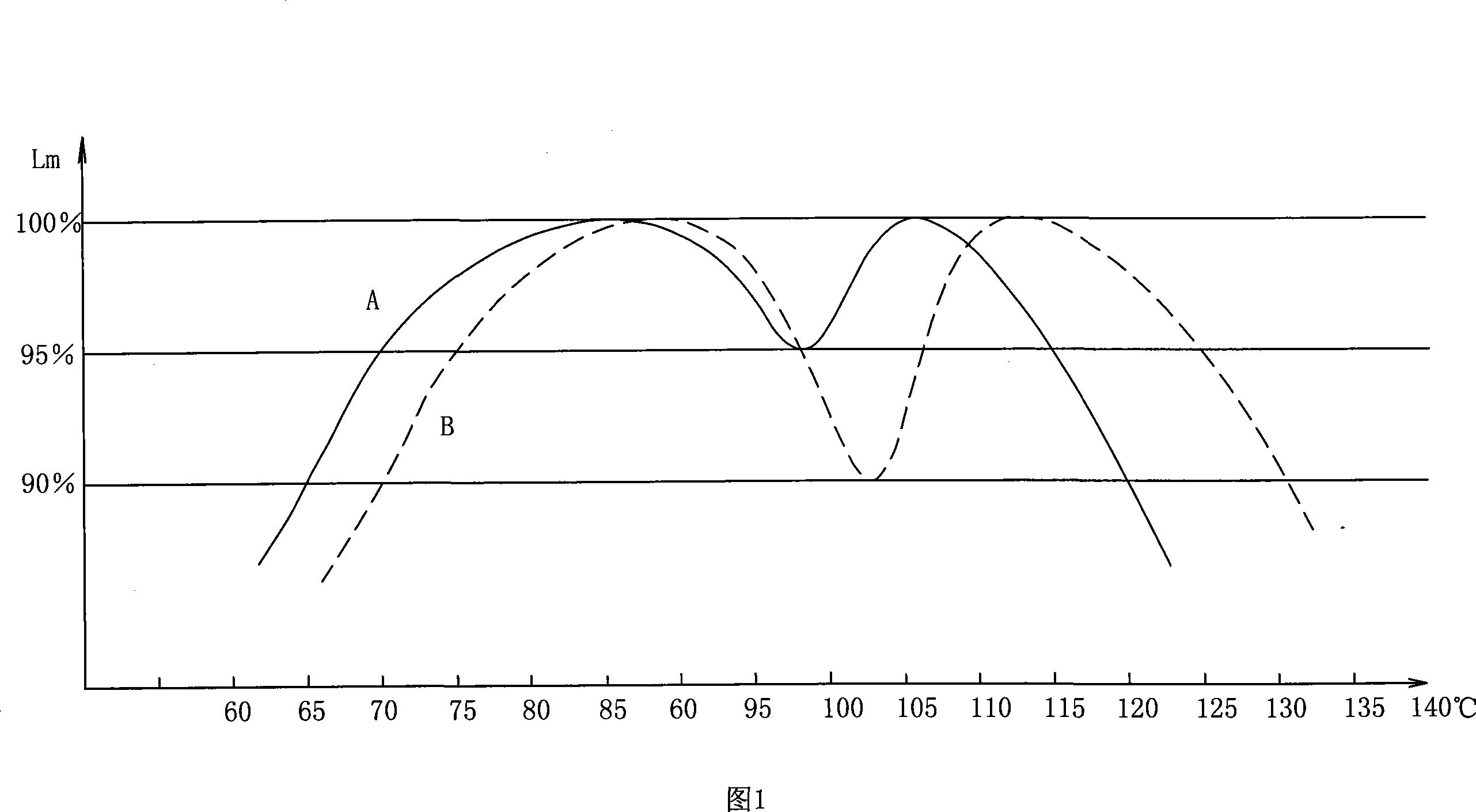

Bismuth indium mercury alloy for low-pressure gas discharging lamp

InactiveCN101041872AStabilized mercury vapor pressureImprove luminous efficiencyGas discharge lamp detailsGas-discharge lampAlloy

The invention discloses a Bi-In-Hg alloy of low-pressure gas discharge lamp, which is characterized by the following: setting the weight rate of Bi, In and Hg at 66-82:15-28:3-8; controlling mercury vapour pressure in the lamp about 1.0Pa stably between 70 and 110 deg.c; improving luminous efficiency, stability and consistency effectively.

Owner:何志明

Mercury removal agent for treating waste water containing mercury

InactiveCN102476860AHigh selectivityWill not cause secondary pollutionWater contaminantsTreatment with anaerobic digestion processesSodium bicarbonateIron sulfate

The invention discloses mercury removal agent for treating waste water containing mercury, which is formed by compounding engineering bacillus, inorganic matters and organic aldehyde. The engineering bacillus includes one or two of engineering acidithiobacillus, iron-oxidizing bacteria, mercury removal bacillus and pseudomonas cepacia, the inorganic matters include one or two of sodium chloride, sodium bicarbonate, sodium bisulfate and ferrous sulfate, and the organic aldehyde includes one or two of cyclohexyl formaldehyde, trioxymethylene, O-phthalic aldehyde and p-fluoro benzaldehyde. Undera condition with a pH (potential of hydrogen) value ranging from 6.0 to 8.0, the composite mercury removal agent is added into waste water with mercury concentration ranging from 50mg / L to 1000mg / L, the mass ratio of the fed mercury removal agent to the waste water ranges from 1:100 to 1:500, fermentation is carried out for 24 to 48 hours under an anaerobic condition, mercury in the waste water can be converted into mercury steam, the mercury steam is absorbed by hydrogen sulfide gas to generate precipitated mercuric sulfide, and accordingly the purpose of removing the mercury is achieved.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com