Method for microwave low-temperature treatment of acid mud and synchronous recovery of selenium and mercury

A technology for low-temperature treatment and recovery of selenium, applied in the field of environmental resource utilization, can solve the problems of small mercurous chloride market, long process flow, high energy consumption, etc., and achieve great environmental and economic benefits, high purity, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

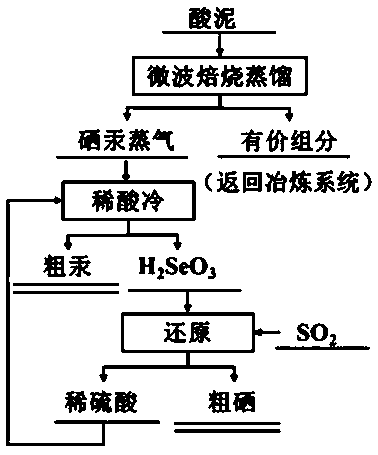

[0020] Such as figure 1 Shown, this microwave low-temperature treatment acid mud synchronously reclaims the method for selenium mercury, and it comprises the following steps:

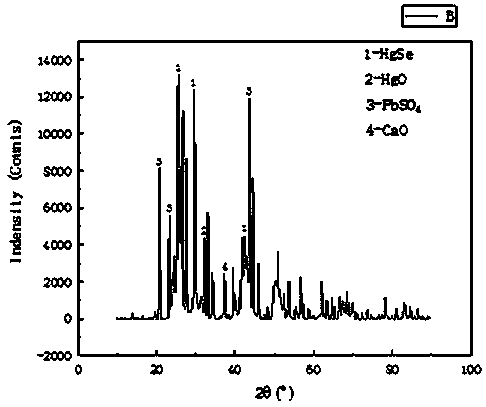

[0021] Step 1. Acid mud (the source of acid mud includes copper acid mud, the main components include: valuable components of lead, zinc and copper, selenium-containing components and mercury-containing components, the acid mud XRD diagram is as follows figure 2 As shown, the phases in which mercury exists include HgO, HgS, HgSO 4 and HgSe, the phases of selenium include HgSe, the content of Hg in the acid mud is 1wt%, and the content of Se is 50wt%) using microwave roasting and distillation to 300°C, keeping it for 5min to obtain selenium mercury vapor and valuable components;

[0022] Step 2, pass the selenium mercury vapor obtained in step 1 into dilute acid (dilute sulfuric acid, dilute acid concentration is 5wt%), the crude mercury enrichment time is 5min, obtain crude mercury precipitation and s...

Embodiment 2

[0026] Such as figure 1 Shown, this microwave low-temperature treatment acid mud synchronously reclaims the method for selenium mercury, and it comprises the following steps:

[0027] Step 1. Acid mud (the source of acid mud includes lead-acid mud, the main components include: valuable components of lead, zinc and copper, selenium-containing components and mercury-containing components, wherein the phases of mercury include HgO, HgS, HgSO 4 and HgSe, the phases of selenium include HgSe, the content of Hg in the acid mud is 25wt%, and the content of Se is 25wt%) using microwave roasting and distillation to 450°C, holding for 30min to obtain selenium mercury vapor and valuable components;

[0028] Step 2, pass the selenium mercury vapor obtained in step 1 into dilute acid (dilute sulfuric acid, dilute acid concentration is 15wt%), the crude mercury enrichment time is 30min, obtain crude mercury precipitation and selenic acid solution;

[0029] Step 3, reducing the selenic acid ...

Embodiment 3

[0032] Such as figure 1 Shown, this microwave low-temperature treatment acid mud synchronously reclaims the method for selenium mercury, and it comprises the following steps:

[0033] Step 1. Acid mud (the source of acid mud includes zinc acid mud, the main components include: valuable components of lead, zinc and copper, selenium-containing components and mercury-containing components, wherein the phases of mercury include HgO, HgS, HgSO 4 and HgSe, the phases of selenium include HgSe, the content of Hg in the acid mud is 50wt%, and the content of Se is 1wt%) using microwave roasting and distillation to 600°C, holding for 60min to obtain selenium mercury vapor and valuable components;

[0034] Step 2, pass the selenium mercury vapor obtained in step 1 into dilute acid (dilute nitric acid, dilute acid concentration is 20wt%), the crude mercury enrichment time is 60min, obtain crude mercury precipitation and selenic acid solution;

[0035] Step 3, the selenic acid solution tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com