Processing method of chlorine-containing tail gas produced by mercuric chloride production

A treatment method and mercuric chloride technology, applied in the chemical industry, can solve the problems of sodium hypochlorite solution backlog, transportation, storage, difficulty in use, restriction on the production of mercuric chloride, etc. The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

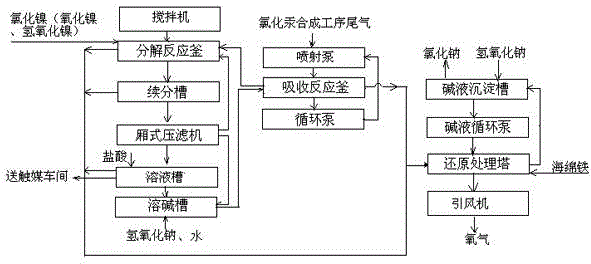

Image

Examples

Embodiment 1

[0017] A treatment method for chlorine-containing tail gas in the production of mercuric chloride, comprising the steps of:

[0018] (1) Sodium hypochlorite generation: The tail gas containing chlorine and mercuric chloride vapor from the mercuric chloride synthesis process is sucked by the jet pump, and the jet pump uses sodium hydroxide solution with a weight concentration of 10% as the transmission medium. During the stroke of the jet pump Carry out gas-liquid mixing and absorption reaction, and the generated sodium hypochlorite enters the absorption reactor: the mercuric chloride vapor cools down and dissolves in the solution in the absorption reactor, the air escapes from the surface of the solution in the absorption reactor and is drawn from the top of the reactor, and the circulation pump Continuously transport the solution in the absorption reactor to the jet pump, until the pH value of the solution in the absorption reactor is 11, the sodium hydroxide solution is all c...

Embodiment 2

[0024] A treatment method for chlorine-containing tail gas in the production of mercuric chloride, comprising the steps of:

[0025] (1) Sodium hypochlorite generation: The tail gas containing chlorine and mercuric chloride vapor from the mercuric chloride synthesis process is sucked by the jet pump, and the jet pump uses sodium hydroxide solution with a weight concentration of 10% as the transmission medium. During the stroke of the jet pump Carry out gas-liquid mixing and absorption reaction, and the generated sodium hypochlorite enters the absorption reactor: the mercuric chloride vapor cools down and dissolves in the solution in the absorption reactor, the air escapes from the surface of the solution in the absorption reactor and is drawn from the top of the reactor, and the circulation pump Continuously transport the solution in the absorption reactor to the jet pump until the pH value of the solution in the absorption reactor is 10.5, and all the sodium hydroxide solution...

Embodiment 3

[0031] A treatment method for chlorine-containing tail gas in the production of mercuric chloride, comprising the steps of:

[0032] (1) Sodium hypochlorite generation: The tail gas containing chlorine and mercuric chloride vapor from the mercuric chloride synthesis process is sucked by the jet pump, and the jet pump uses sodium hydroxide solution with a weight concentration of 8% as the transmission medium. During the stroke of the jet pump Carry out gas-liquid mixing and absorption reaction, and the generated sodium hypochlorite enters the absorption reactor: the mercuric chloride vapor cools down and dissolves in the solution in the absorption reactor, the air escapes from the surface of the solution in the absorption reactor and is drawn from the top of the reactor, and the circulation pump Continuously transport the solution in the absorption reactor to the jet pump, until the pH value of the solution in the absorption reactor is 111, the sodium hydroxide solution is all c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com