Actinic chemistry reaction device and method for synthesizing provitamin D3

A technology of photochemical reaction and synthesis method, applied in the field of photochemical reactors, can solve problems such as instability and unsuitability for industrial production, and achieve the effect of high utilization rate of light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

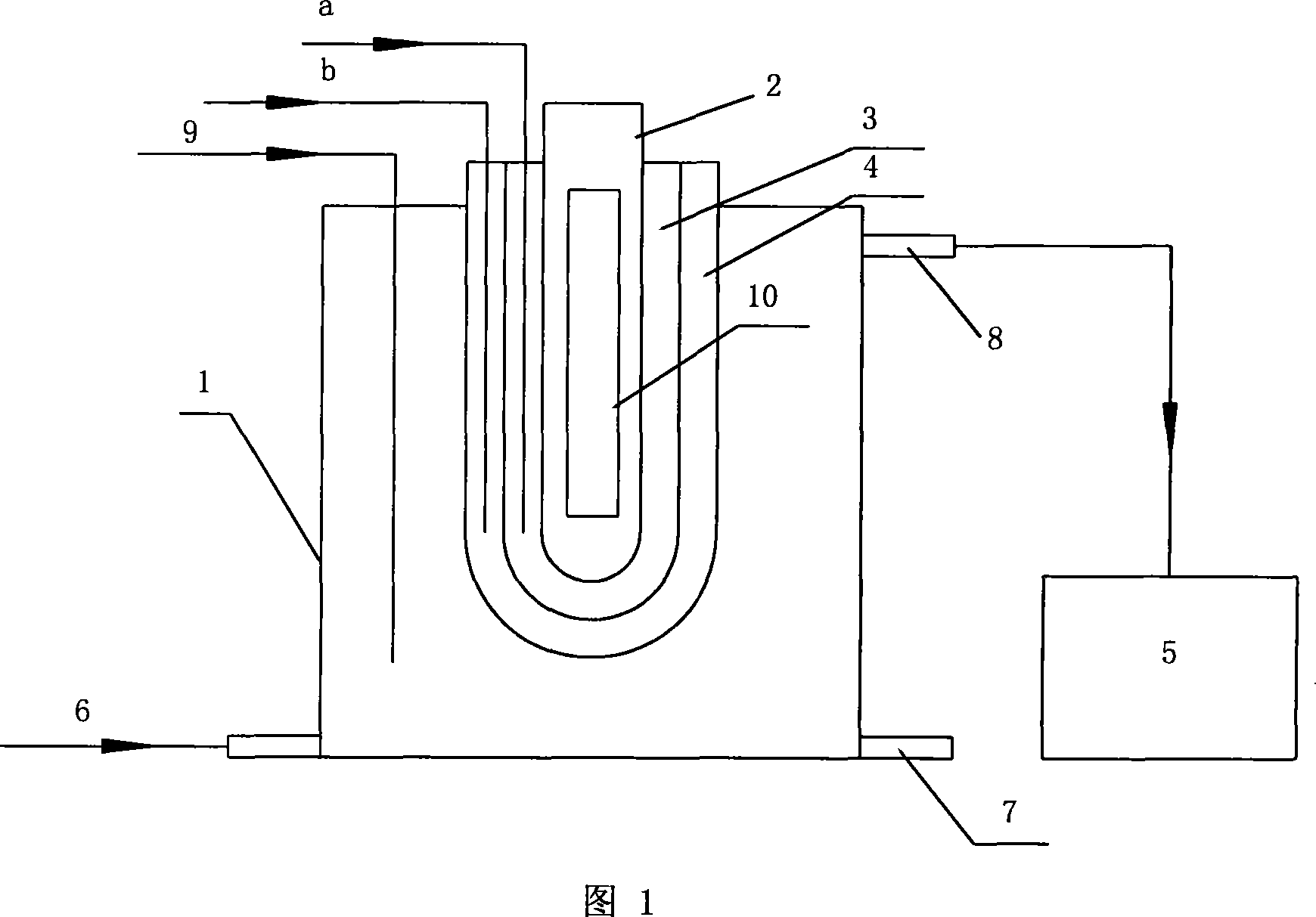

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 5 g of the 7-DHC sample in 1000 ml of ethanol, the 7-DHC content is 97.5%, and the container is evacuated and protected by nitrogen. Use 0.7M NaWO 4 As filter a, 1.1MCoSO 4 -5% H 2 SO 4 As a filter b. The filter solution a is passed through the inner jacket of the actinator, and the filter solution b is passed through the outer jacket of the actinator. The filter solution is circulated closely through the condenser to maintain a constant temperature of the filter solution at 24°C. Turn on the mercury lamp power supply, when the current reaches the rated current, start feeding, the 7-DHC solution is fed from the bottom of the actinator, adjust the flow meter to 6L / h, and at the same time pass nitrogen through the feeding tube to control the material layer of the actinator mixing. The reaction temperature under illumination is 36.3℃, and the finished solution is sampled and tested after illumination. Vitamin D is pre-examined. 3 The content is 68.7%.

[0026] Pre-vit...

Embodiment 2

[0028] Dissolve 5 g of the 7-DHC sample in 1000 ml of ethanol, and the 7-DHC content is 97.1%. The container is evacuated and protected by nitrogen. Use 0.7M NaWO 4 , 0.7MPbAc as filter a, 1.05MCoSO 4 -6%H 2 SO 4As a filter b. The filter solution a is passed through the inner jacket of the actinator, and the filter solution b is passed through the outer jacket of the photochemical device. The filter solution is circulated through the condenser to keep the filter solution at a constant temperature of 25°C. Turn on the power of the mercury lamp and start feeding when the current reaches the rated current. The 7-DHC solution is fed from the bottom of the actinator, and the flowmeter is adjusted to 6L / h. At the same time, nitrogen is introduced from the feed pipe to mix the material layer of the actinator. The reaction temperature was 35.5°C under illumination. Sampling and testing of the finished liquid after illumination, pre-vitamin D 3 The content is 68.2%.

Embodiment 3

[0030] Dissolve 5 g of the 7-DHC sample in 1000 ml of ethanol, and evacuate the container with nitrogen protection. Use 0.75M NaWO with 7-DHC content 97.7% 4 As filter a, 1.0MCoSO 4 , 0.8MNiSO 4 -5% H 2 SO 4 As a filter b. The filter solution a is passed through the inner jacket of the photochemical device, and the filter solution b is passed through the outer jacket of the photochemical device. The filter solution is circulated through the condenser to maintain a constant temperature of the filter solution at 23°C. Turn on the power of the mercury lamp and start feeding when the current reaches the rated current. The 7-DHC solution is fed from the bottom of the actinator, and the flowmeter is adjusted to 6L / h. At the same time, nitrogen is introduced from the feed pipe to mix the material layer of the actinator. Illumination reaction temperature is 36℃, sampling and testing of finished liquid after illumination, pre-vitamin D 3 The content is 68.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com