Microwave ultra violet light source

An ultraviolet light source and microwave technology, applied in the field of ultraviolet light source, can solve the problems of electrode ignition, low power and low efficiency, and achieve the effects of rapid ignition, high power and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

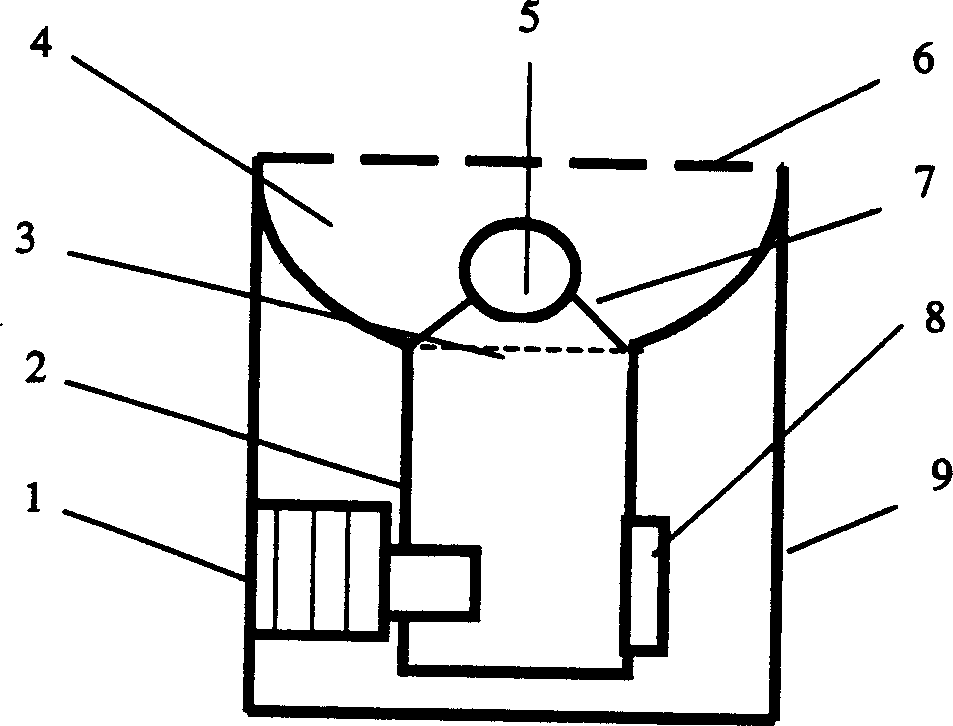

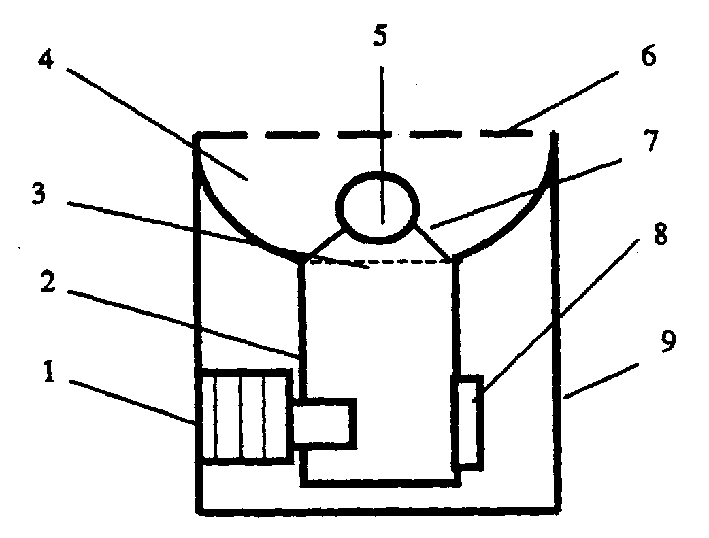

[0014] Electrodeless Microwave UV Lamp

[0015] 1kw / 2450MHz (50-1000w adjustable) microwave magnetron 1 generates microwave power of 50-1000w, the microwave is transmitted to the microwave resonant cavity 4 through the waveguide 2, and the ultraviolet lamp 5 is placed on the lamp holder 7 in the microwave resonant cavity 4 , the microwave in the microwave resonant cavity 4 passes through the shell glass of the ultraviolet lamp 5 and acts on the gas in the lamp to ionize the gas to generate plasma to emit ultraviolet light. The shell of the ultraviolet lamp 5 is made of quartz glass, and the size of the ultraviolet lamp 5 is about φ50mm spherical bulb, evacuated to 10 -3 After the Pa is filled with mercury and argon, the filling amount of mercury is 1-10 grams, and the filling amount of argon meets the working pressure of about 50-200 Pa in the lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com