Method and apparatus for producing mercury vapor with standard concentration

A standard concentration and mercury gas technology, which is applied in the direction of measuring devices, test sample preparation, instruments, etc., to achieve the effect of simplifying the structure of the mercury vapor generator and the waste gas treatment system used for the calibration of environmental monitoring instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

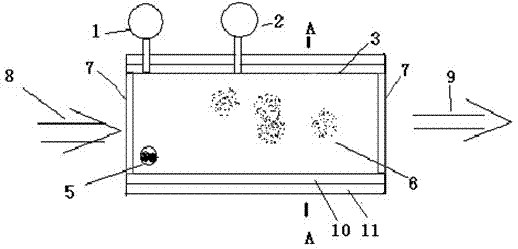

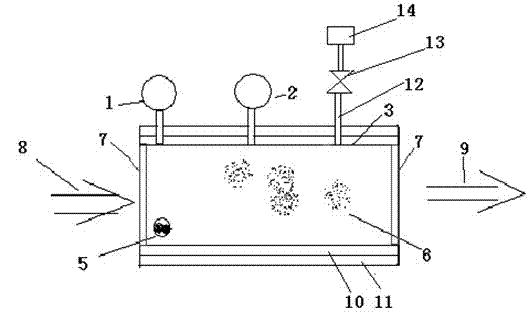

[0032] The refrigeration and heating device used in the mercury gas generator for calibration is a device heated by electric current, such as figure 2 As shown, the device is a resistance wire heating layer 10 wrapped outside the sample cell, changing the heating current, changing the temperature of the sample cell, thereby changing the saturated vapor pressure of mercury in the sample cell, and then changing the mercury gas concentration, the resistance wire The heating layer is provided with an insulation layer 11 outside, such as image 3 Shown, in order to maintain the stability of the sample cell temperature.

Embodiment 2

[0034] Depend on Figure 4 As shown, since the sample cell cannot be completely sealed, the vacuum of the sample cell will drop after long-term use, causing the measured pressure in the sample cell to be not equal to the saturation pressure of mercury vapor. Increased suction pipe 12 on the top, valve 13 is housed on the suction pipe, connects vacuum pump 14 behind. After the vacuum drops, you can open the valve, start the vacuum pump to evacuate the sample pool, then close the valve, stop the vacuum pump, and keep the vacuum in the sample pool.

Embodiment 3

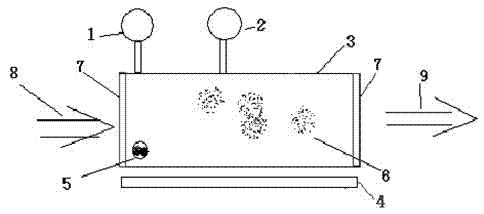

[0036] When calibrating very low concentrations, because the liquefaction pressure of mercury is very low, the mercury gas concentration corresponding to the corresponding mercury saturation pressure at room temperature may be too high. figure 1 The cooling and heating device used in the mercury gas generator for intermediate calibration is a semiconductor refrigeration device. By changing the polarity of the power supply of the semiconductor refrigeration device, the polarity of the sample cell can be cooled or heated.

[0037] Attached table: Mercury gas saturation pressure and temperature comparison table

[0038] Saturation vapor pressure of mercury at different temperatures

[0039] temperature / ℃ Vapor pressure / mmHg temperature / ℃ Vapor pressure / mmHg temperature / ℃ Vapor pressure / mmHg -38.0 1.45×10 -6 122.0 0.8198 282.0 164.39 -36.0 1.97×10 -6 124.0 0.9004 284.0 172.21 -34....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com