Method for low-temperature and efficient preparation of large-size graphene

A graphene, large-size technology, applied in the field of graphene preparation, can solve the problems of high cost, long preparation time, high preparation temperature, etc., and achieve the effect of simple method, large size, low-temperature and high-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

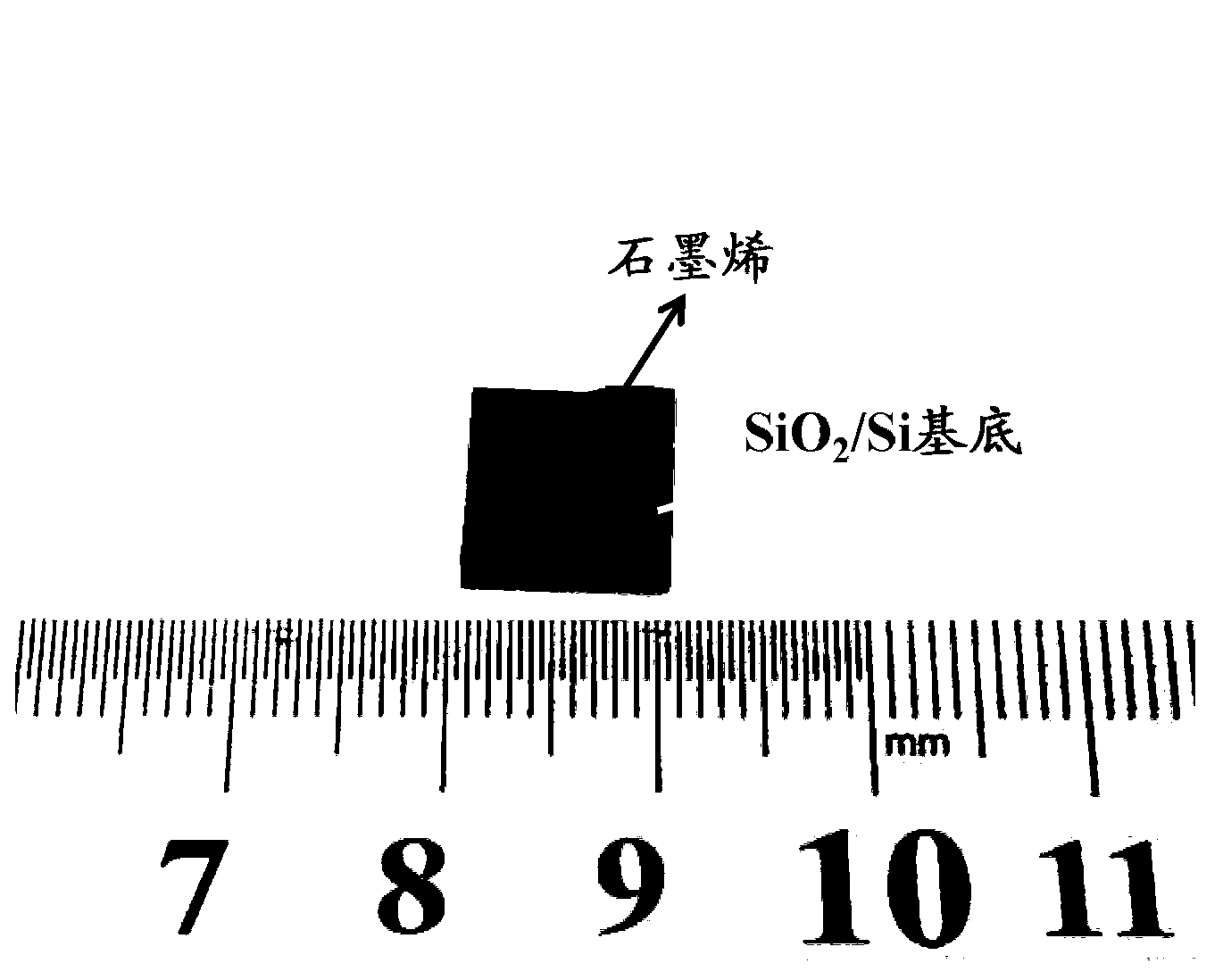

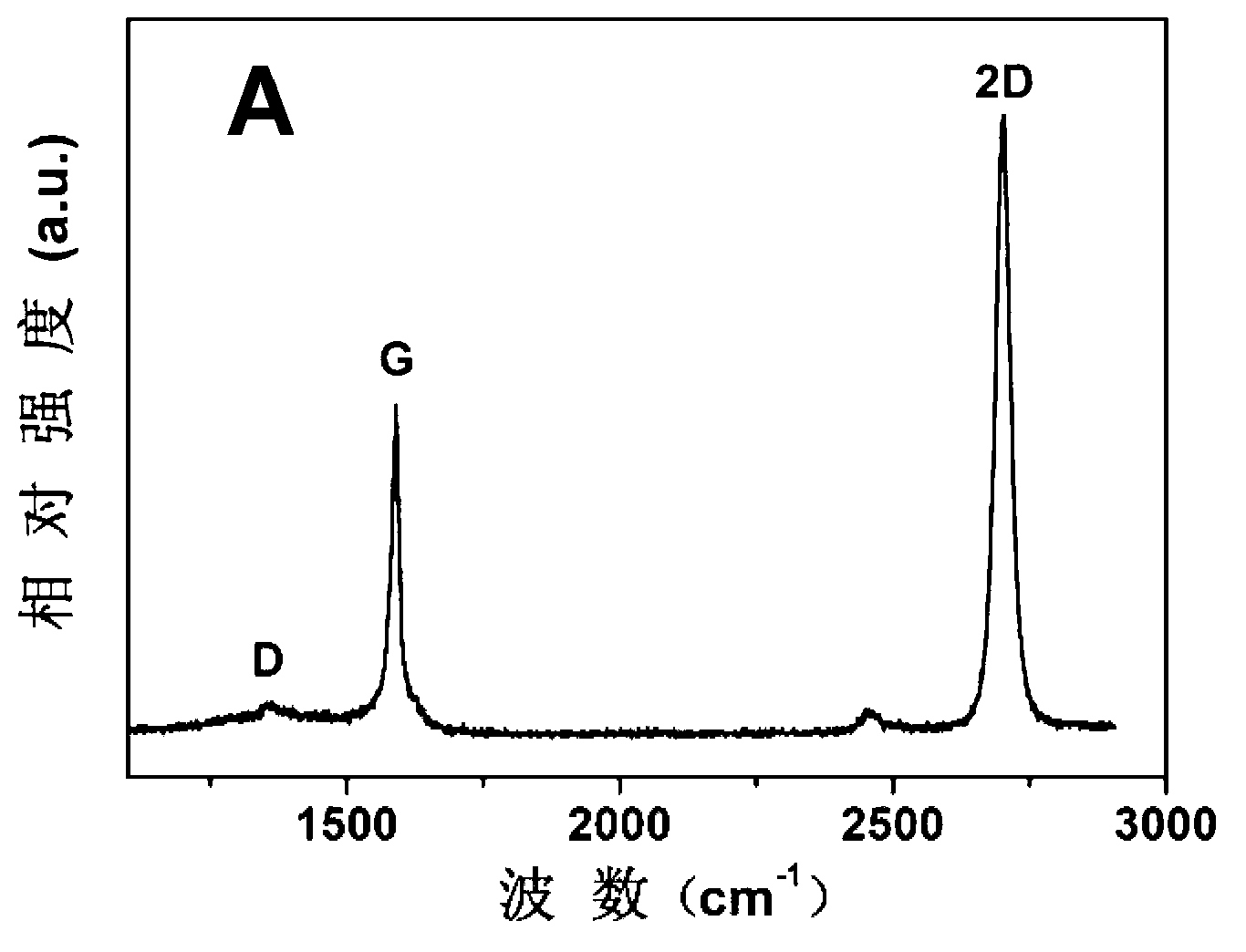

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the method for preparing large-scale graphene at low temperature and high efficiency in this embodiment is carried out according to the following steps:

[0022] 1. Put the metal substrate into the plasma-enhanced chemical vapor deposition equipment, evacuate to 5Pa, and inject H 2 , H 2 The flow rate is 20sccm, the working pressure is 200Pa, then the temperature is raised, and the working temperature is 500-700°C within 40 minutes, and the heat preservation and annealing treatment is 30 minutes;

[0023] 2. After the annealing treatment, continue to feed Ar and CH 4 gas, adjust H 2 , Ar and CH 4 The flow rates are 40sccm, 80sccm and 1-8sccm respectively, the working pressure is 1000Pa, the RF power frequency of the deposition system is 13.56MHz, the RF power is 200W, and the deposition time is 10-300 seconds;

[0024] 3. After the deposition is over, turn off the RF power supply and heating power supply, and stop feeding CH 4 gas, with Ar ...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the metal substrate used in step 1 needs to be ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10-20 minutes before use. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the working temperature in Step 1 is 510-690°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com