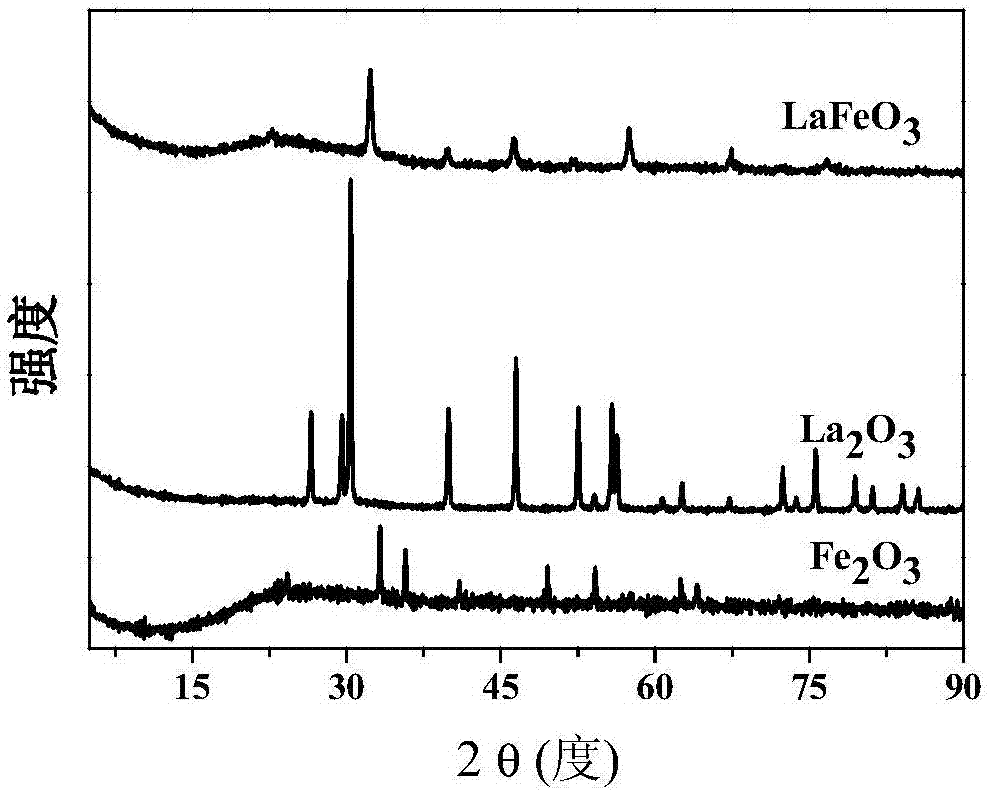

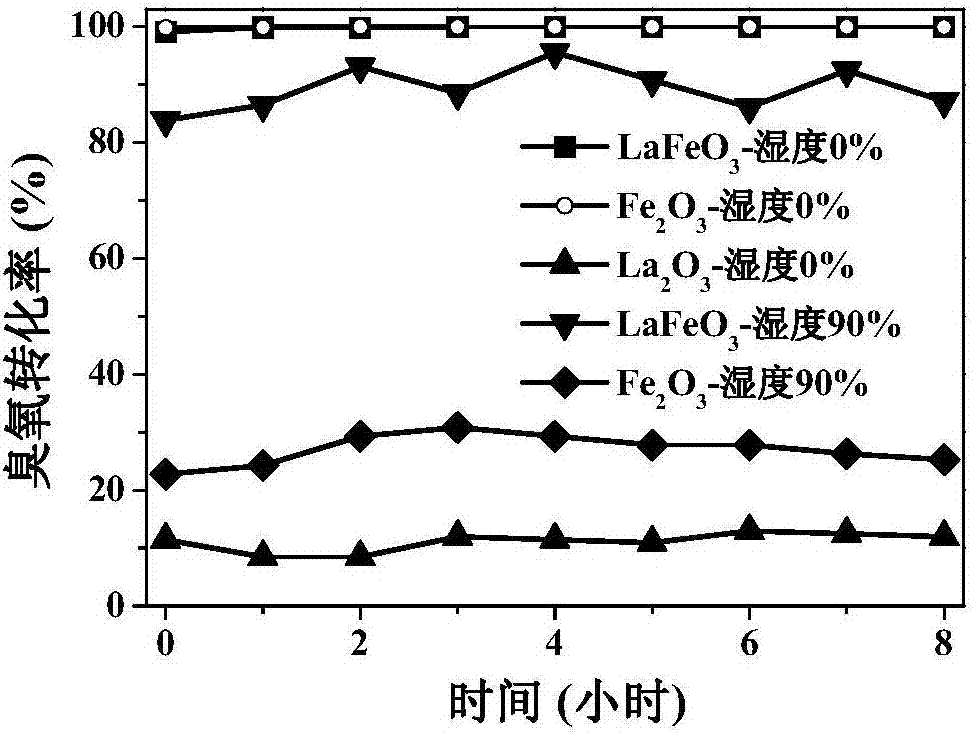

Perovskite ozone decomposition catalyst and preparation method and application thereof

A perovskite type, ozone decomposition technology, which is applied in the field of air pollution purification, can solve the problems of large interference of catalytic performance and inability to meet the requirements of ozone catalytic treatment, and achieve the effect of simple process, excellent catalytic decomposition activity and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare the perovskite type ozonolysis catalyst according to the following method:

[0043] (1) Dissolve lanthanum nitrate, ferric nitrate, and citric acid in deionized water at a molar ratio of 1:1:2, stir and dissolve to obtain a mixed solution with a concentration of lanthanum nitrate of 1mol / L; slowly add ammonia water dropwise to the mixed solution to adjust The pH value of the solution was 6.5. During this process, the solution gradually changed from reddish brown to yellow-green sol. The sol was transferred to an oil bath at 70°C and stirred for 4 hours to form a yellow-green gel;

[0044] (2) Transfer the gel obtained in step (1) to a porcelain boat and place it in a constant temperature drying oven at 130°C to dry for 12 hours. The yellow-green gel turns into a dark green xerogel; When the material is ignited, the material will self-propagate and burn. During the process, the material gradually turns into yellow coral-like particles and releases a large amount ...

Embodiment 2

[0051] Prepare the perovskite type ozonolysis catalyst according to the following method:

[0052] (1) lanthanum nitrate, ferric nitrate, copper nitrate, citric acid are dissolved in deionized water according to the molar ratio of 1:0.95:0.05:2, stirring and dissolving to obtain the mixed solution that the concentration of lanthanum nitrate is 1.5mol / L; Slowly add ammonia water dropwise to adjust the pH value of the solution to 6.8. During this process, the solution gradually changes from reddish brown to yellow-green sol. Transfer the sol to an oil bath at 65°C and stir for 3 hours to form a yellow-green gel;

[0053] (2) Transfer the gel obtained in step (1) to a porcelain boat and place it in a constant temperature drying oven at 100°C to dry for 12 hours. The yellow-green gel will turn into a dark green xerogel; When the material is ignited, the material will self-propagate and burn. During the process, the material gradually turns into yellow-green coral-like particles an...

Embodiment 3

[0059] Prepare the perovskite type ozonolysis catalyst according to the following method:

[0060] (1) Dissolve lanthanum nitrate, ferric nitrate, nickel nitrate, citric acid in deionized water according to the molar ratio of 1:0.9:0.1:2, stir and dissolve to obtain a mixed solution whose concentration of lanthanum nitrate is 2mol / L; Slowly add ammonia water to adjust the pH value of the solution to 7. During this process, the solution gradually changes from reddish brown to yellow-green sol. Transfer the sol to an oil bath at 90°C and stir for 3.5 hours to form a yellow-green gel;

[0061] (2) Transfer the gel obtained in step (1) to a porcelain boat and place it in a constant temperature drying oven at 120°C to dry for 15 hours. The yellow-green gel will turn into a dark green xerogel; When the material is ignited, the material will self-propagate and burn. During the process, the material gradually turns into dark green coral-like particles and releases a large amount of am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com