Compound microbial bacterial preparation for degrading crop straw and preparation method and application of compound microbial bacterial preparation

A technology for compounding microbial inoculants and crop straws, which is applied in the field of microbial fermentation, can solve the problems of inability to meet the production speed of straws, low utilization rate of straws, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

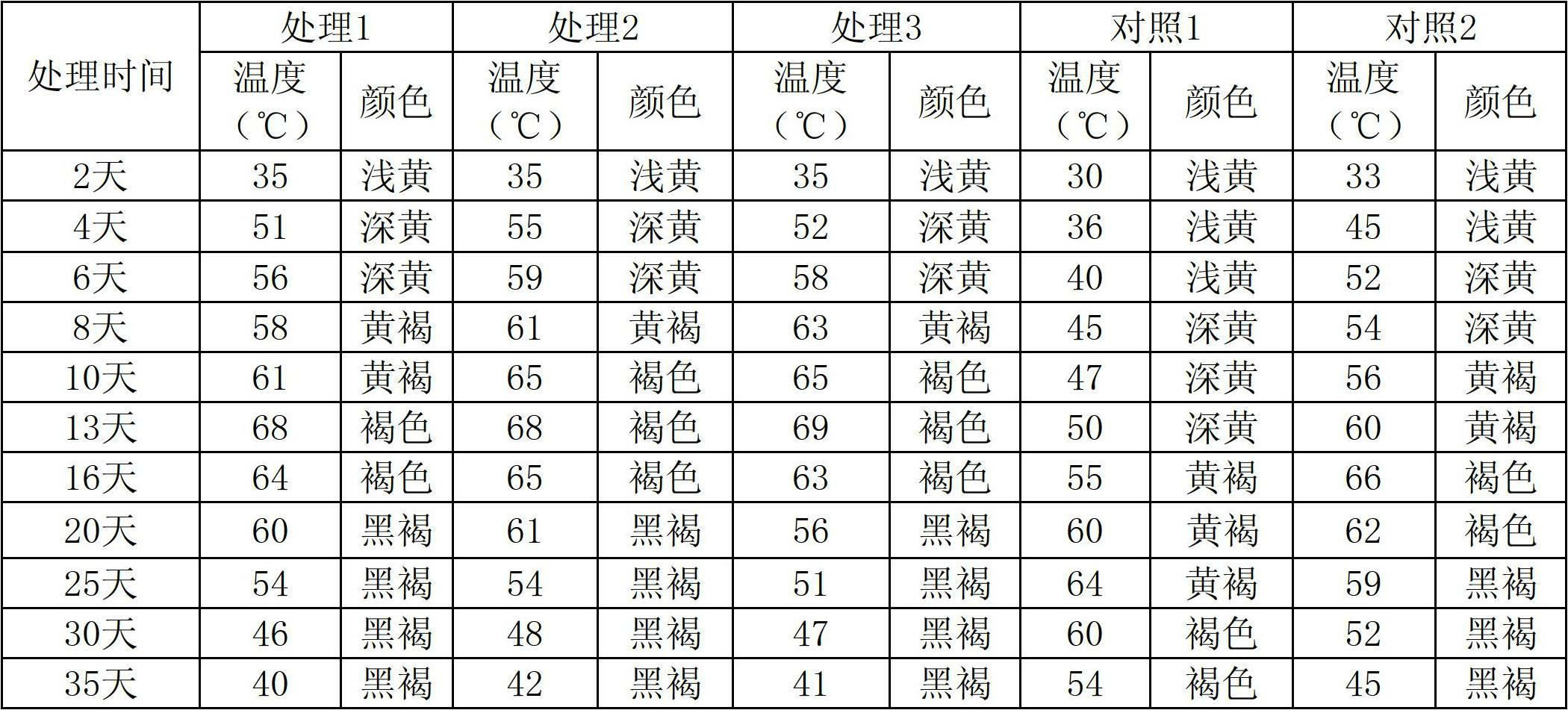

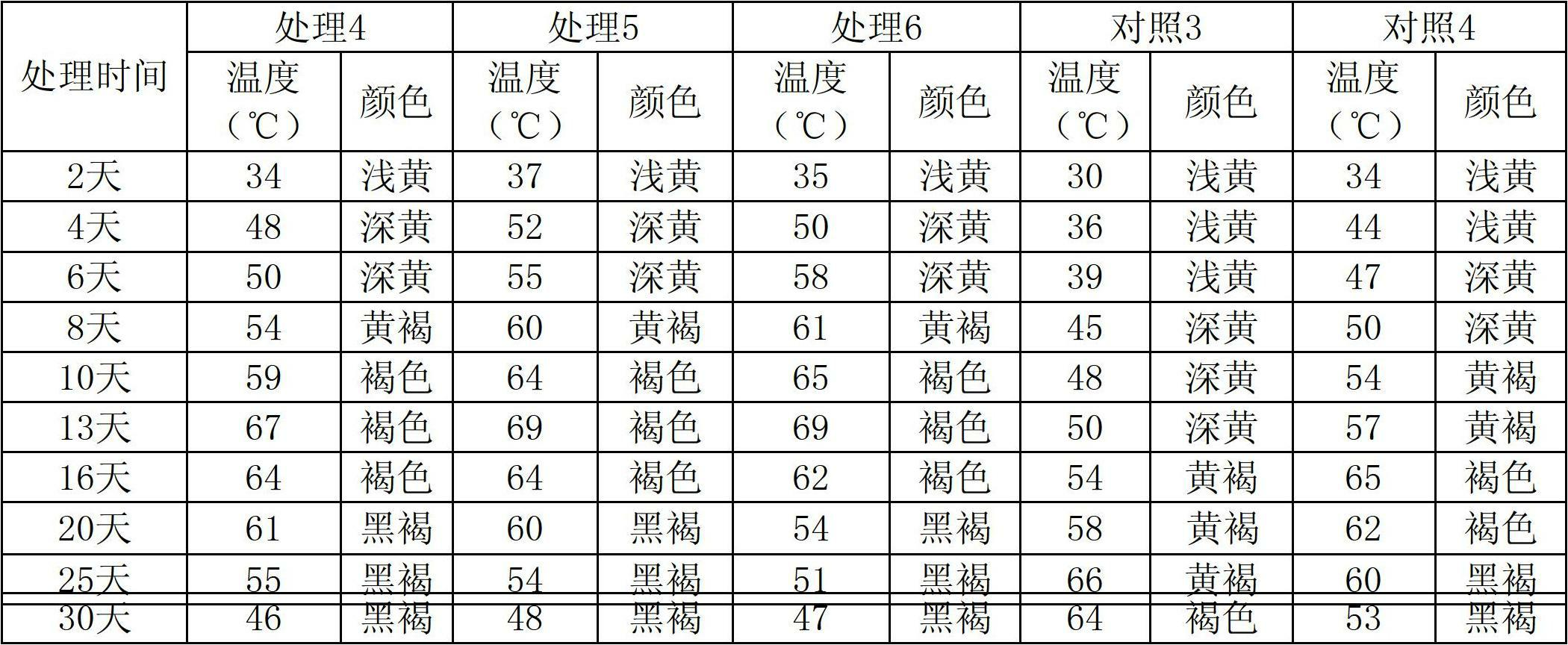

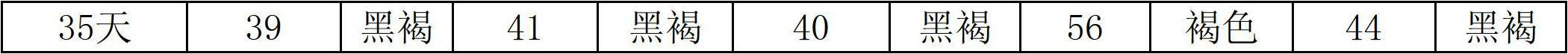

Image

Examples

Embodiment 1

[0050] A preparation method for a compound microbial bacterial agent for degrading crop stalks, comprising the following steps:

[0051] (1) Inoculate Bacillus subtilis CICC10088 in LB liquid medium, culture it at 37°C for 24 hours, then inoculate Bacillus subtilis in solid medium A at an inoculation amount of 10wt%, and culture it at 37°C for 3 days, Prepared 10 live bacteria containing Bacillus subtilis CICC10088 10 Each / g of solid microbial agent A;

[0052] (2) Inoculate Bacillus cereus ACCC03002 in LB liquid medium, culture it at 30°C for 24 hours, then inoculate Bacillus cereus in solid medium B at an inoculation amount of 10wt%, and culture it at 30°C for 3 days, the number of live bacteria containing Bacillus cereus ACCC03002 was 8×10 9 A / g of solid bacterial agent B;

[0053] (3) Inoculate Aspergillus niger CICC41130 on PDA solid medium, culture at 28°C for 60 hours, add sterile water to adjust the spore concentration to 10 8 Individual / ml, then inoculate Aspergil...

Embodiment 2

[0070] Adopt the method as described in Example 1, the difference is that step (9) solid bacterial agent A, solid bacterial agent B, solid bacterial agent C, solid bacterial agent D, solid bacterial agent E, solid bacterial agent F, solid bacterial agent The mixing weight ratio of bacterial agent G and solid bacterial agent H is 3:1:3:1:3:1:3:1.

[0071] In the prepared composite microbial agent for degrading crop stalks, each gram of the composite microbial agent contains: Bacillus subtilis (Bacillus subtilis) viable bacteria count 1.87×10 9 pcs, Bacillus cereus (Bacillus cereus) viable count 5×10 8 , Aspergillus niger (Aspergillus niger) spore number 3.75×10 8 1. Number of spores of Aspergillus niger 1.25×10 8 , the number of spores of Trichoderma reesei 2.81×10 8 The number of spores of Trichoderma viride 9.37×10 7 1. The number of spores of Sporotrichum thermophilic 1.87×10 8 1. Number of spores of Phanerochaete chrysosporium 6.25×10 7 indivual.

Embodiment 3

[0073] Adopt the method as described in Example 1, the difference is that step (9) solid bacterial agent A, solid bacterial agent B, solid bacterial agent C, solid bacterial agent D, solid bacterial agent E, solid bacterial agent F, solid bacterial agent The mixing weight ratio of agent G and solid bacterial agent H is 2:1:1:1:2:1:1:1.

[0074] In the prepared composite microbial agent for degrading crop stalks, each gram of the composite microbial agent contains: Bacillus subtilis (Bacillus subtilis) viable bacteria count 2×10 9 , Bacillus cereus (Bacillus cereus) live bacteria count 8×10 8 , Aspergillus niger (Aspergillus niger) spore count 2×10 8 , the number of spores of Aspergillus niger 2×10 8 , Trichoderma reesei spore number 3×10 8 1. The number of spores of Trichoderma viride 1.5×10 8 1, the number of spores of Sporotrichum thermophilic 10 8 Phanerochaete chrysosporium spores 10 8 indivual.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com