A kind of cellulose-based composite material for ammonia gas detection and preparation method thereof

A composite material, cellulose-based technology, applied in the field of cellulose-based composite material for ammonia detection and its preparation, can solve problems such as low percolation value, and achieve reduced permeation value, high reusability, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

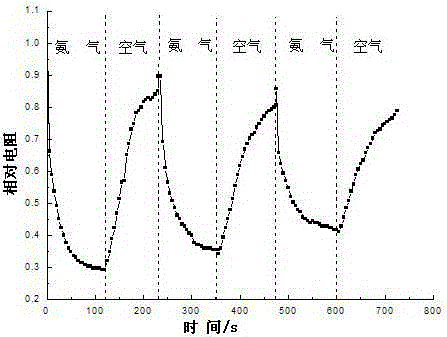

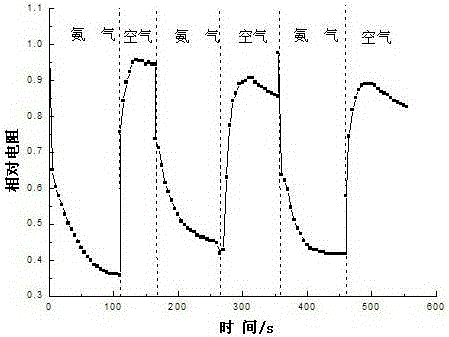

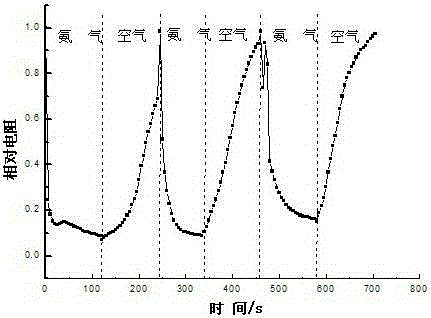

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be further described below in conjunction with examples and accompanying drawings, but the implementation and protection of the present invention are not limited thereto.

[0025] The proportioning ratio table 1 of embodiment 1~4, its preparation method concrete steps are as follows:

[0026] ① Carbon nanotubes (diameter 2nm, length 15μm, specific surface area 700m 2 / g, with a purity of 95%), heated to reflux at 120°C for 4 hours with concentrated nitric acid, and then placed in a sodium dodecylsulfonate-ethanol (sodium dodecylsulfonate mass fraction: 4%) solution at 70°C Heat and stir for 90 minutes, and finally wash with distilled water until neutral and put it in a desiccator for later use;

[0027] ②Put 1g of ionic liquid in a test tube, add 0.02g of cotton fiber according to the calculated amount (take 1 / 10 each time, add in batches), blow in nitrogen and heat and stir in an oil bath at a temperature of 100°C;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com