Cellulose-based gas-sensitive conductive composite material and preparation method thereof

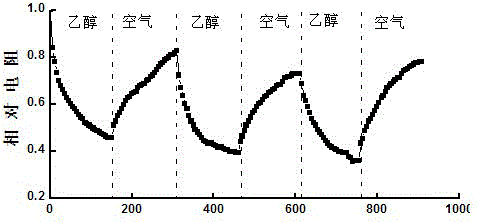

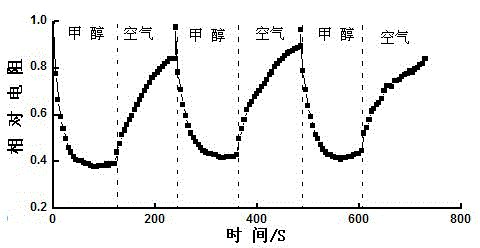

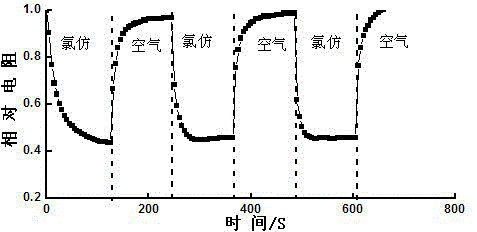

A conductive composite material and composite material technology, applied in the field of cellulose-based gas-sensitive conductive composite material and its preparation, can solve problems such as low percolation value, achieve low percolation value, high sensitivity, high stability and repeatability usability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The ratio table 1 of embodiment 1~5, its preparation method concrete steps are as follows:

[0027] ①Heat and reflux the conductive filler at 120°C for 4 hours with concentrated nitric acid, then place it in a sodium dodecylsulfonate-ethanol (4% sodium dodecylsulfonate) solution and heat and stir at 70°C 90min, and finally washed with distilled water to neutrality and then placed in a desiccator for later use;

[0028] ②Add 0.0175g of chitosan to 1g of ionic liquid, blow in nitrogen and heat and stir in an oil bath at a temperature of 100°C. After 3, add cotton fibers in batches;

[0029] ③After the above substances are completely dissolved (about 1h), add conductive filler with a mass fraction of 1.1% according to the calculated amount, and continue stirring with nitrogen gas for 10min;

[0030] ④ Apply the sticky substance obtained on a glass electrode plate, wash the deionized liquid with deionized water, and vacuum-dry it at 80°C for 10 minutes to obtain a composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com