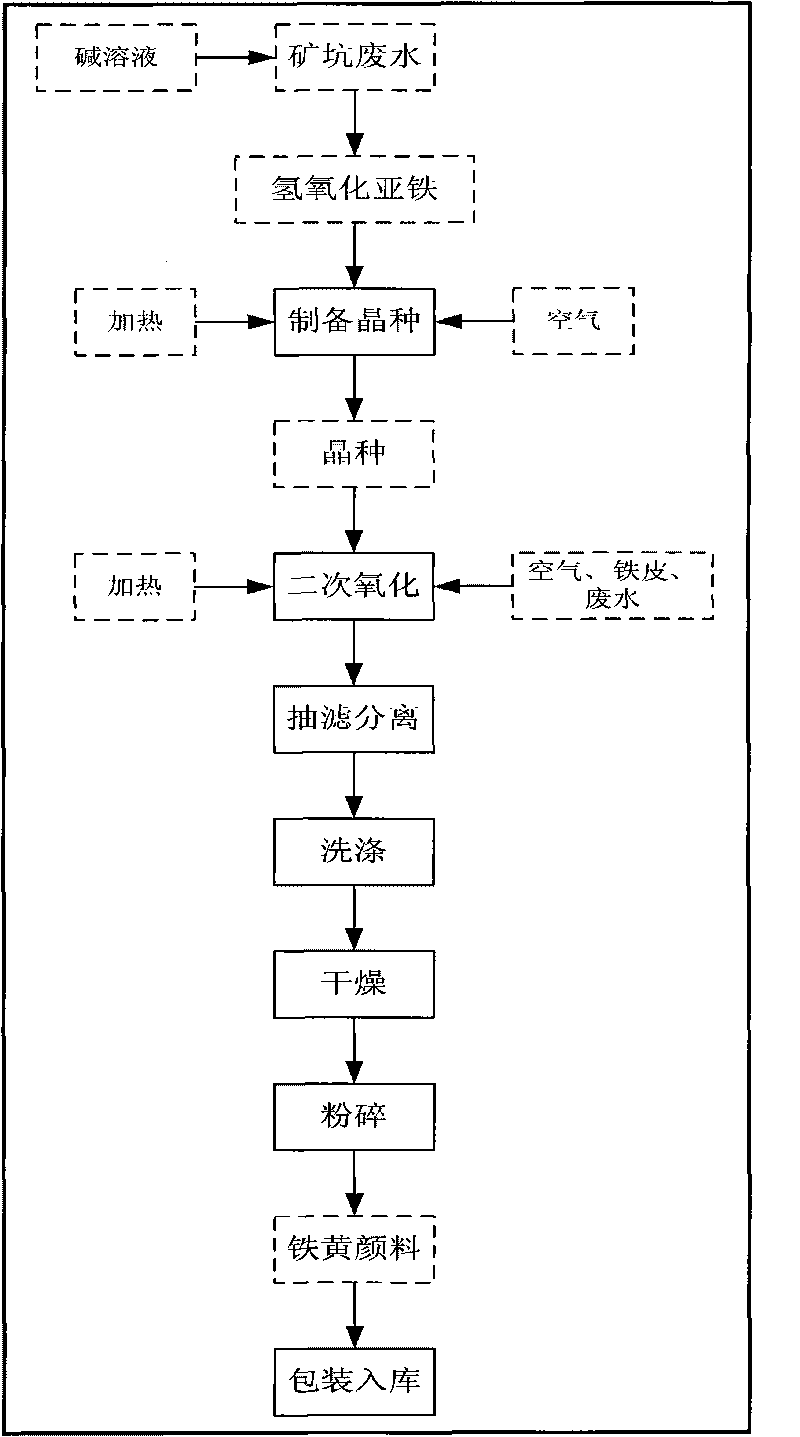

Method for preparing iron oxide yellow pigment by carrying out resourceful treatment on pyrite wastewater

A technology for iron oxide yellow and pyrite, applied in iron oxide, mining wastewater treatment, chemical instruments and methods, etc., can solve the problems of long treatment period, inapplicability, and large initial investment, and achieve obvious social and environmental benefits, Realize the effect of resource processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A. Add NaOH aqueous solution (10wt%) to 500ml of pyrite wastewater (Niujiaowan closed mine wastewater under Zhejiang Juhua Chemical Co., Ltd.) to adjust the pH value to 5. Stand still to obtain the precipitate ferrous hydroxide and the supernatant, discard the supernatant.

[0047] B. In the reactor, add the precipitated ferrous hydroxide, pass through 1m 3 / h of air and heating for oxidation reaction, the temperature is controlled at 20°C, and the stirring speed is 100r / min. After 4 hours of reaction, the pH value of the reaction system is 3.5, and the reaction is stopped. Prepare 300ml of pure yellow iron oxide topaz seeds.

[0048] C, iron oxide topaz seed is dropped into oxidation tank, then add the pyrite waste water of 600ml (detection wherein the content of ferrous sulfate is 6wt%, the density of pyrite waste water is 1g / ml, what use below is the same batch of sulfur Iron ore wastewater, the content of ferrous sulfate is the same) and 20g iron powder, pass into...

Embodiment 2

[0052] Other operations and conditions are the same as in Example 1, except that NaOH aqueous solution (30wt%) is added in step A to adjust the pH value to 7.5. Other operations and conditions are the same as in Example 1 to obtain 4.0232g of iron oxide yellow pigment.

Embodiment 3

[0054] Other operation and condition are the same as embodiment 1, and difference is, the amount of air that feeds in the step B is 3m 3 / h, other operations and conditions were the same as in Example 1 to obtain 4.0369g of iron oxide yellow pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com