Method for preparing monodisperse Fe3O4 magnetic nanoparticles

A magnetic nanoparticle, monodisperse technology, applied in the direction of inorganic material magnetism, ferrous oxide, iron oxide/ferric hydroxide, etc., can solve the problems of expensive and toxic reagents, achieve stable quality, simple synthesis process, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

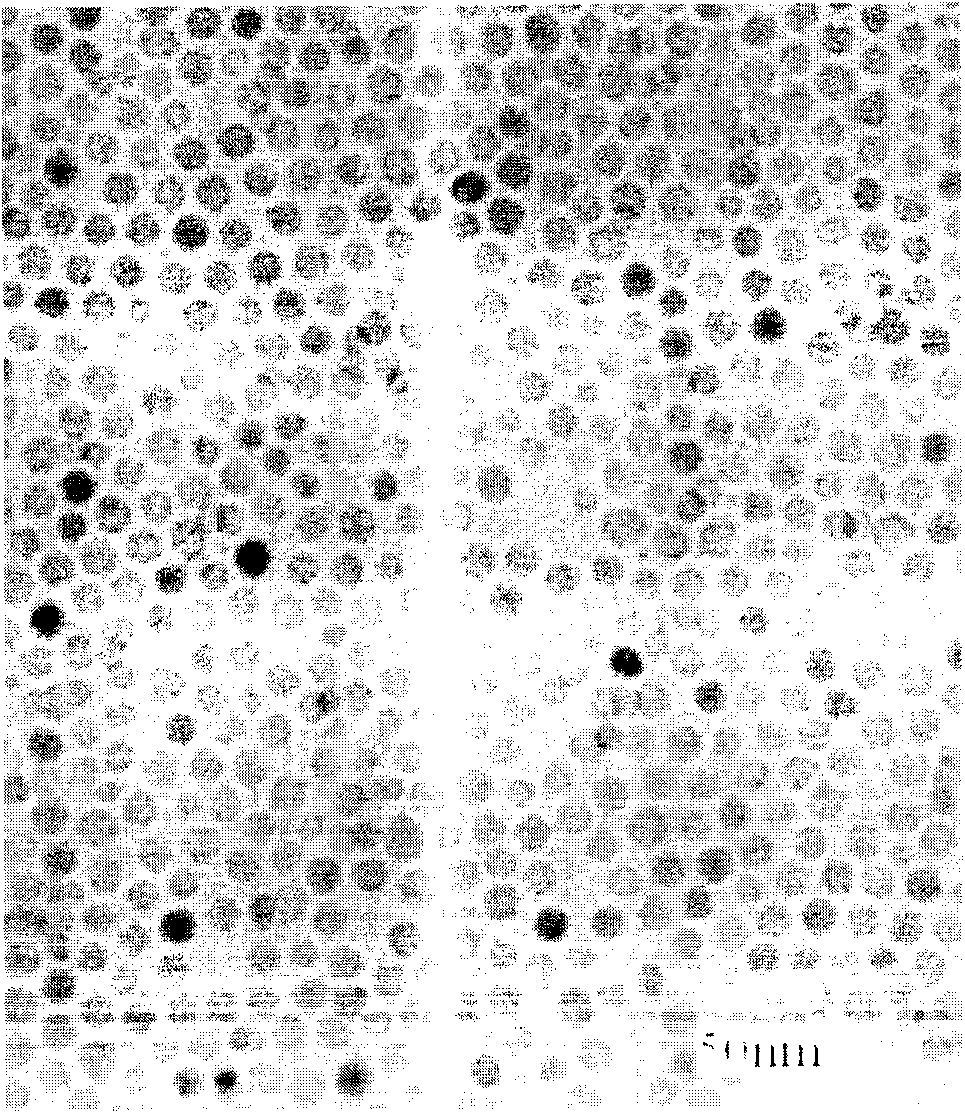

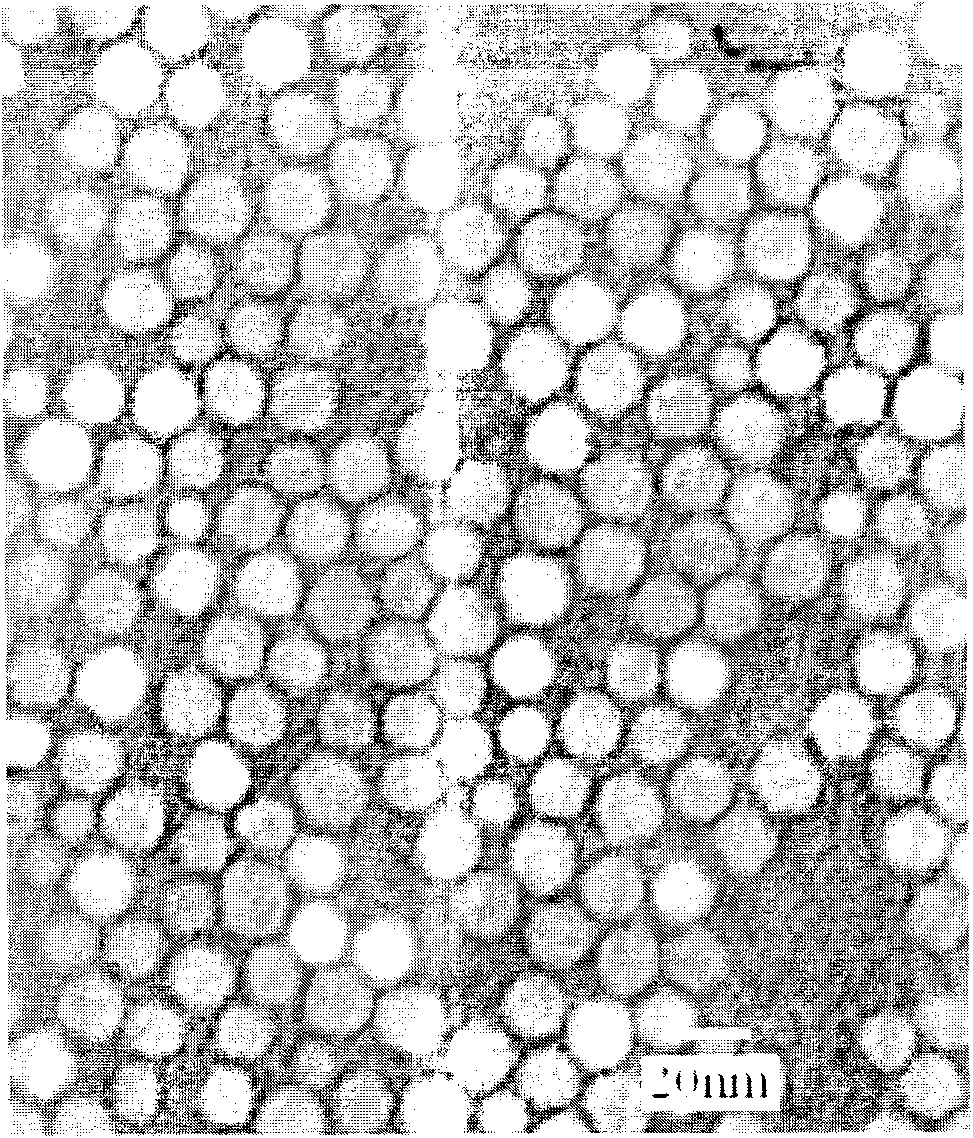

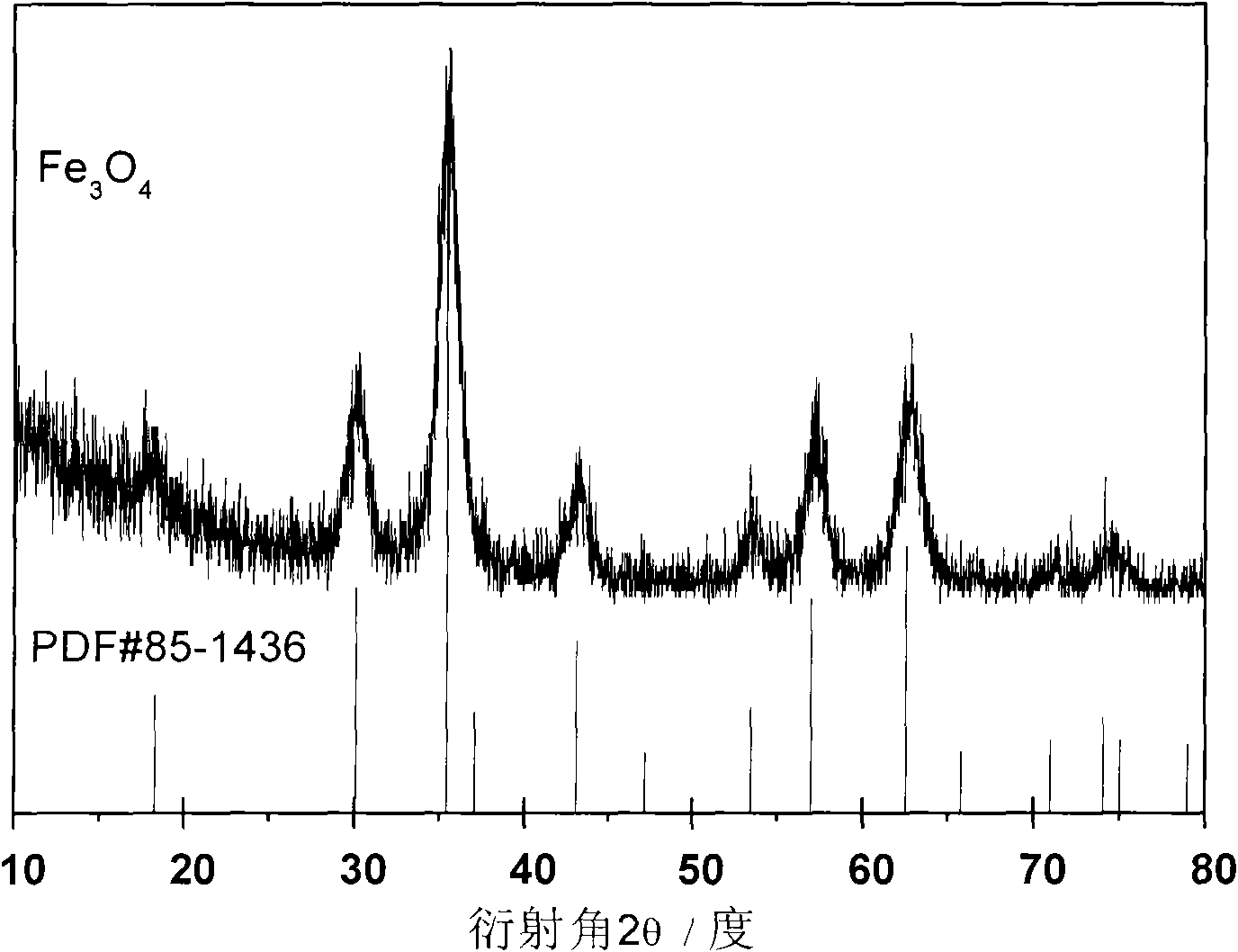

[0014] According to the molar ratio of precursor: stabilizing agent is 1: 4, and the molar ratio of precursor: high temperature organic solvent is 1: 10, accurately weigh the precursor iron oxide yellow (Fe 2 o 3 ·H 2 O) 10mmol, stabilizer oleic acid 40mmol and high-temperature organic solvent 1-octadecene 100mmol (35.5mL) were added to a 250mL three-necked flask reactor, an air condenser was installed, and then, magnetically stirred, reacted at 320°C for 10 hours, and the reaction After finishing, cool down to room temperature naturally. Then, add 180mL of precipitating agent of toluene and absolute ethanol mixed solution (volume ratio is 1: 2), ultrasonic treatment for 20 minutes, after separating with permanent magnet or centrifuge, obtain black precipitate, so far is called separation step; The separation step was repeated twice, and the obtained black precipitate was dried at 50°C. Its yield is about 1.5g, the product Fe 3 o 4 The average particle size of the magneti...

Embodiment 2

[0016] According to the molar ratio of precursor: stabilizing agent is 1: 7, and the molar ratio of precursor: high temperature organic solvent is 1: 10, accurately weigh the precursor iron oxide yellow (Fe 2 o 3 ·H 2 O) 10mmol, stabilizer oleic acid 70mmol and high-temperature organic solvent 1-octadecene 100mmol (35.5mL) were added in a 250mL three-necked flask reactor, an air condenser was installed, and then, magnetically stirred, reacted at 300°C for 6 hours, and the reaction After finishing, cool down to room temperature naturally. Then, add the precipitant of 180mL of toluene and isopropanol mixed solution (volume ratio is 1: 3), ultrasonic treatment 20 minutes, after separating with permanent magnet or centrifuge, obtain black precipitation, so far is called separation step; The separation step was repeated twice, and the obtained black precipitate was dried at 50°C. Its yield is about 1.3g, the product Fe 3 o 4 The average particle diameter of the magnetic nanopa...

Embodiment 3-14

[0017] Embodiment 3-14: implement according to the parameters in the table, the operation method is the same as embodiment 1 or 2.

[0018] Example 3-14 parameter table

[0019]

[0020] Acetone 1 / 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com