Preparation process of medium temperature resistant iron oxide yellow

A technology of iron oxide yellow and production process, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of small color change when heated, resistance to medium temperature iron oxide yellow, red color, poor heat resistance, etc. , to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

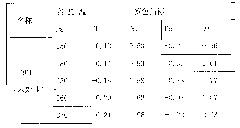

[0011] Commercially available ordinary iron oxide yellow filter cake is 80 kg, its brand name is 301, and its water content is 72%. Put the raw materials and water into the beater according to the ratio, and control the slurry concentration at about 25%. Adjust the parameters of the beater: 1200 rpm At the same time, add the auxiliary agent aluminum silicate, start beating, keep warm according to the experimental steps and put in the neutralizer, separate and beat the powder to obtain product #301, and do the temperature resistance test of the raw materials and products (Pigment dry powder heat resistance test method GB1716-79) to get The data are as follows (based on unprocessed raw materials):

[0012]

[0013]

[0014] Ordinary iron yellow begins to change color at 150°C, but the color change of iron yellow at 280°C is DE≤0.5, so its heat resistance is at 280°C

Embodiment 2

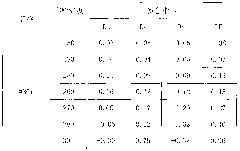

[0016] Commercially available common iron oxide yellow is 80 kg, its brand name is 301, and its water content is 72%. Put the raw materials and water into the beater according to the ratio, and control the slurry concentration at about 25%. Adjust the parameters of the beater: 1200 rpm, At the same time, add the auxiliary agent aluminum silicate, start beating, add neutralizer for heat preservation, separate and beat the powder to obtain product #301, the effect of the amount of auxiliary agent on pigment 311 is as follows:

[0017] Auxiliary dosage (%)

[0018] When the amount of additives exceeds 0.5, the conductivity and water-soluble salts both exceed the standard, so the amount of additives should be below 0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com