Method for preparing high purity iron oxide yellow and iron oxide red using titanium dioxide byproduct ferrous sulfate

A technology for iron oxide red and iron oxide yellow, applied in the field of preparation of iron oxide yellow and iron oxide red, can solve the problems of complex production process, low product purity and high production cost, and achieves short process flow, high impurity removal degree, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

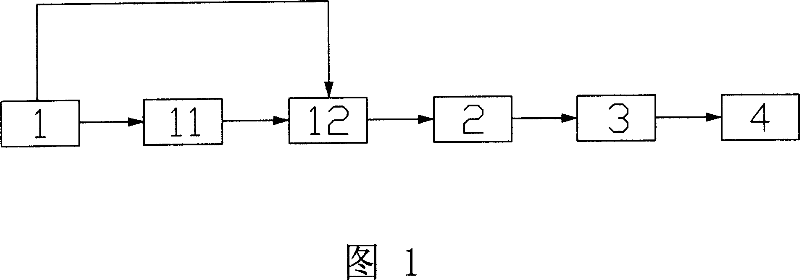

[0029] The method for preparing high-purity iron oxide yellow and iron oxide red by ferrous sulfate by-product of titanium dioxide, the concentration of ferrous sulfate is 20%, and the sulfuric acid method is used to produce titanium dioxide. Also contains Mg, Al, Si, Ca, Ti, Zn, Ba, Mn and other elements. These elements have a great influence on the production of iron oxide yellow and iron oxide red, so the first step is to refine the above-mentioned ferrous sulfate solution 1:

[0030] There are two steps of impurity removal and separation in the process of refining 1. In the present embodiment, the two steps of impurity removal are carried out at room temperature. The first step of impurity removal and separation is to remove titanium 11 and other impurities, dilute with water or adjust with dilute alkaline solution. The pH value of the above solution is greater than 1.5, so that the titanium ion Ti 3+ Complete hydrolysis to form metatitanate H 2 TiO 3 , the hydrolysis p...

Embodiment 2

[0042] In this embodiment, the concentration of ferrous sulfate is 1 mol·L -1 , after dissolving, use concentrated NaOH solution to directly adjust the pH value to 5.5, hydrolyze the titanium and ferric iron in the solution, filter, carry out impurity removal and purification 1, and adjust the pH value of the filtrate after impurity removal and purification 1 with 20% NaOH solution For 3-7, a ferrous sulfate colloid with a dark green solution is obtained. Under the condition that the temperature is lower than 60 °C, the colloid is then oxidized with air for 2 to obtain iron oxide yellow; the iron oxide yellow is calcined at a temperature of 300 °C After 4, it is converted into red iron oxide with a purity of more than 96%, which meets the national standard for producing red iron oxide by sulfuric acid method.

[0043] In the invention, under the condition that the temperature is lower than 60 DEG C, the titanium dioxide by-product ferrous sulfate solution is purified and impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com