High temperature resistant iron oxide yellow pigment and preparation method thereof

An iron oxide yellow, high temperature resistant technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc. The effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

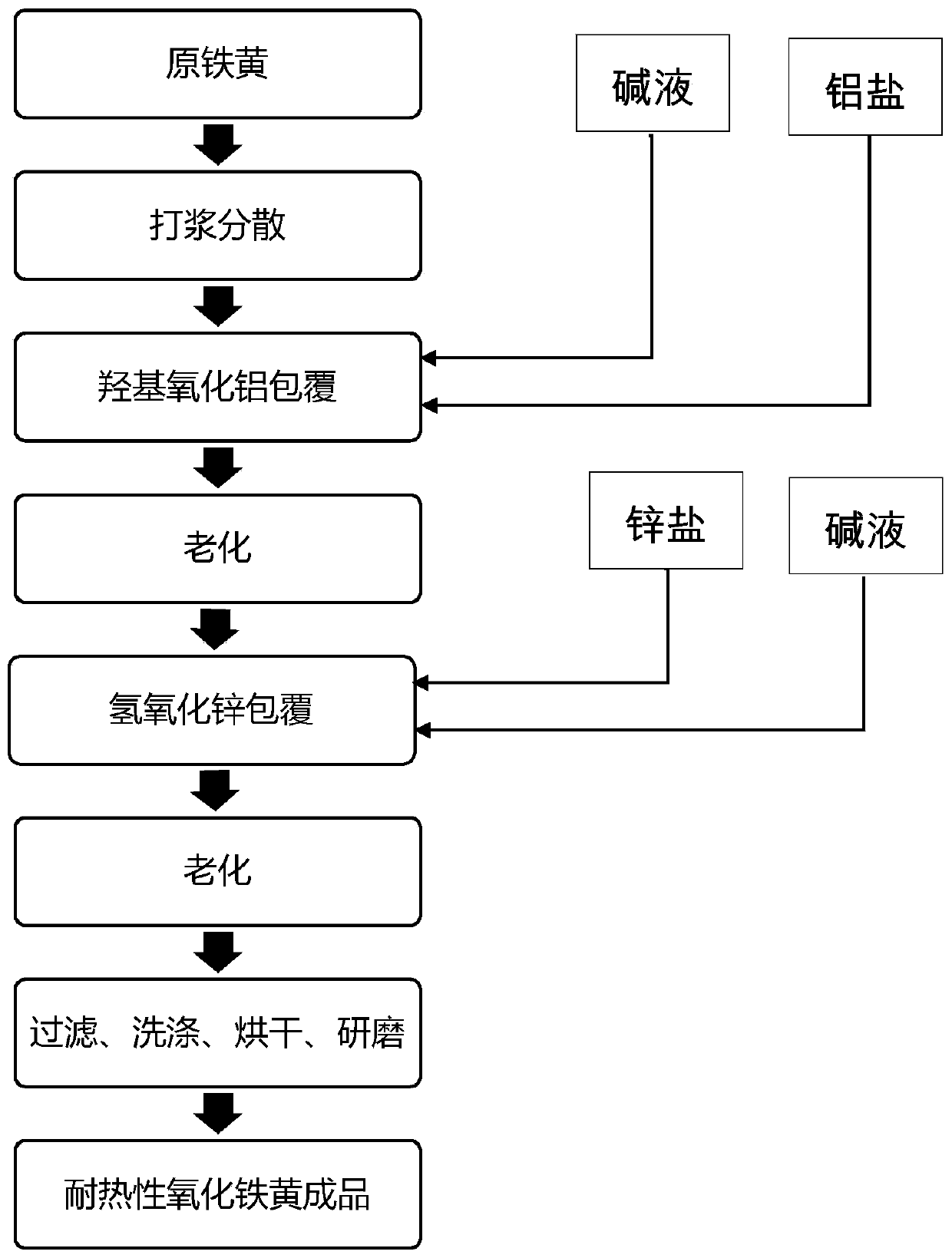

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 coating type iron yellow sample A

[0025] Weigh 10g of yellow iron oxide and disperse it in 300mL of water, sonicate for 10min, and then stir for 1h in a water bath at 80°C to form a homogeneous mixture with a content of yellow iron of 3.3%. Dissolve 0.4g of sodium hydroxide in 100mL of water and pour it into the iron yellow mixture. Then dissolve 0.71g of aluminum sulfate in 150mL of water and slowly drop it into the iron yellow mixed solution. After the solution is dripped, use 0.1wt% aluminum sulfate solution or 0.01wt% sodium hydroxide solution to fix the pH of the iron yellow mixed solution to 9, and then continue Stir and age for 3 hours; dissolve 0.16g of zinc chloride in 150mL of water and slowly drop into the above iron yellow mixture, then slowly add 0.01wt% sodium hydroxide solution into the iron yellow mixture until the pH of the iron yellow mixture reaches 7 , after the solution was dripped, continue to stir and age for 2h. Then, after sucti...

Embodiment 2

[0026] Embodiment 2 coating type iron yellow sample B

[0027] Weigh 50g of yellow iron oxide and disperse it in 500mL of water, sonicate for 10min, then stir in a water bath at 80°C for 1h to form a homogeneous mixture with a content of yellow iron of 10%. Dissolve 4g of sodium hydroxide in 100mL of water and pour it into the iron yellow mixture. Then 7.125g of aluminum sulfate is dissolved in 150mL of water and slowly dripped into the iron yellow mixed solution. After the solution is dripped, titrate the iron yellow mixed solution with 0.1wt% aluminum sulfate solution or 0.01wt% sodium hydroxide solution to make the pH equal to 9, and then Continue to stir and age for 3 hours; dissolve 5.6g of zinc chloride in 150mL of water and slowly drop into the above-mentioned iron yellow mixed solution, then slowly add 0.01wt% sodium hydroxide solution into the iron yellow mixed solution until the pH of the iron yellow mixed solution reaches 7. Continue stirring and aging for 2 hours ...

Embodiment 3

[0028] Embodiment 3 coated iron yellow sample C

[0029] Weigh 10 g of iron oxide yellow and uniformly disperse in 500 mL of water under stirring to form a mixed solution with a content of iron yellow of 2%. Take 100mL of 0.5g sodium hydroxide and dissolve it in water and pour it into the above-mentioned iron yellow mixed solution. Then 1.0g of aluminum nitrate is dissolved in 150mL of water and slowly dripped into the iron yellow mixed solution. After the solution is dripped, titrate the iron yellow mixed solution with 0.1wt% aluminum nitrate solution or 0.01wt% sodium hydroxide solution to make the pH equal to 9, and then Continue to stir and age for 3 hours; dissolve 0.91g of zinc chloride in 150mL of water and slowly drop into the above-mentioned iron yellow mixed solution, and then slowly drop into the iron yellow mixed solution with 0.01wt% sodium hydroxide solution until the pH of the iron yellow mixed solution reaches 7. Continue stirring and aging for 2 hours after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com